Working safely with beeswax is paramount. To melt it without incident, you must use an indirect heat source like a double boiler or a crockpot, keep the temperature low (around 155°F / 68°C), and never leave it unattended. Always wear protective gear and keep a fire extinguisher within reach, as beeswax is flammable.

The core principle of melting beeswax safely is temperature control. Because it is a flammable material, your entire process must be designed to heat the wax gently and indirectly, preventing it from ever reaching its flashpoint or degrading in quality.

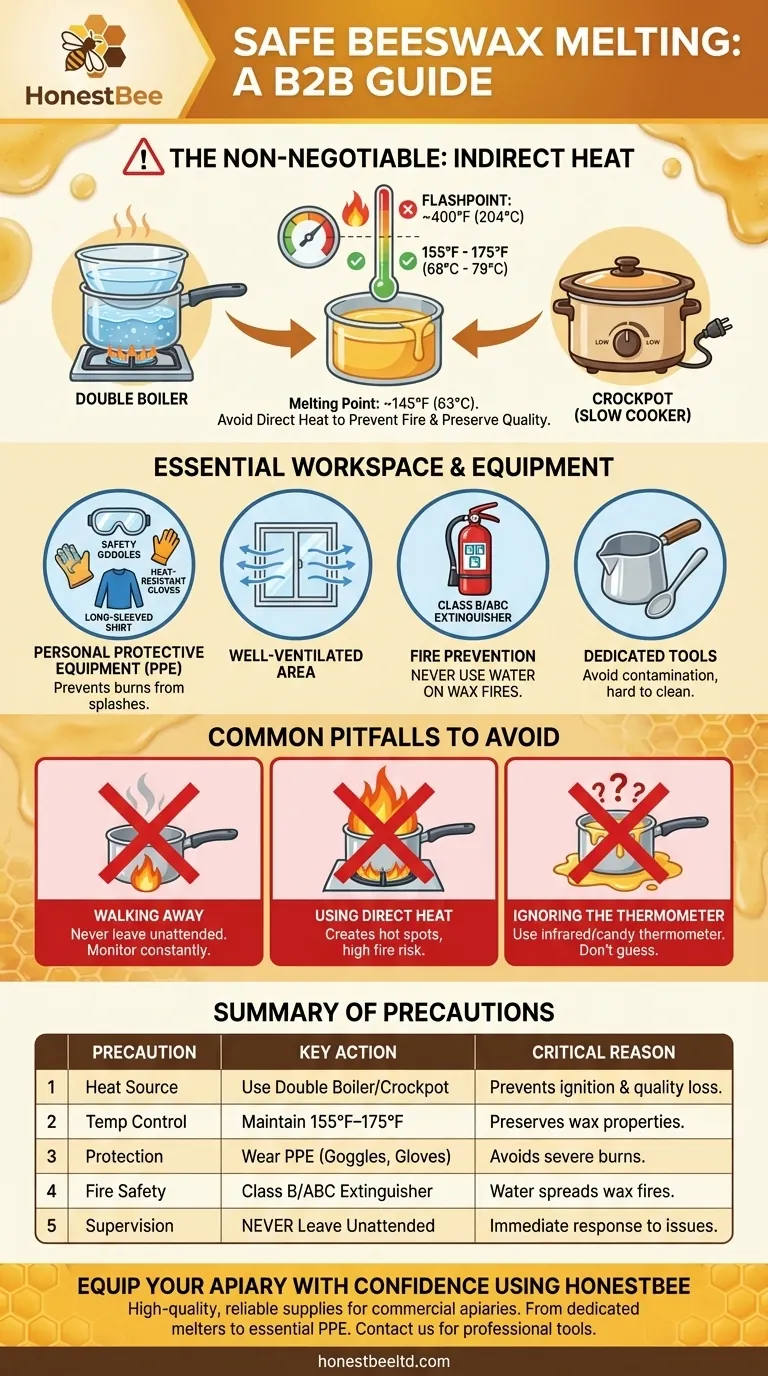

The Core Principle: Why Indirect Heat is Non-Negotiable

Melting beeswax is not like melting butter. Its unique properties require specific handling to avoid significant risks, including fire and loss of quality.

The Flammability Risk

Beeswax is an oil-based, flammable substance. When heated directly on a stove or over an open flame, it can easily overheat.

While it typically melts around 145°F (63°C), its flashpoint—the temperature at which its vapors can ignite—is approximately 400°F (204°C). Direct heat can create hot spots that reach this temperature surprisingly fast, posing a serious fire hazard.

Preserving Wax Quality

Even well below the flashpoint, excessive heat damages the beeswax. Heating it above 175°F (79°C) can darken its color, diminish its natural honey-like aroma, and degrade its beneficial anti-microbial properties.

Gentle, indirect heating ensures the final product retains its beautiful, natural characteristics.

Proven Indirect Heating Methods

There are two primary methods for safely melting beeswax at home or in a workshop.

- The Double Boiler: This is the most common and accessible method. You place the beeswax in a heat-proof container (like a glass jar or metal pouring pot) and set that container in a larger pot partially filled with water. The simmering water gently and evenly heats the wax.

- The Crockpot (Slow Cooker): For larger batches, a dedicated crockpot set to "low" is an excellent choice. Place your beeswax in a heat-safe container inside the crockpot. This provides a very stable, low-temperature environment.

Essential Safety Equipment and Workspace Setup

Preparing your equipment and environment is just as important as the heating method itself. A few simple steps can prevent the most common accidents.

Personal Protective Equipment (PPE)

Hot wax can splash unexpectedly, causing severe burns. Always wear safety goggles to protect your eyes, a long-sleeved shirt, and heat-resistant gloves when handling the melting container or pouring hot wax.

Your Workspace Environment

Work in a well-ventilated area. While the fumes from natural beeswax are generally not hazardous, good airflow is a best practice for any heating process. Ensure your workspace is clean, stable, and free of flammable materials.

Fire Prevention Tools

Keep a Class B or ABC fire extinguisher nearby and ensure you know how to use it. Never use water to extinguish a wax fire, as this can cause the flaming wax to splash and spread.

Use Dedicated Equipment

Beeswax is notoriously difficult to clean from pots and utensils. It is highly recommended to use dedicated equipment for your wax projects to avoid contaminating kitchen supplies.

Common Pitfalls to Avoid

Understanding common mistakes is key to developing safe habits.

Mistake #1: Walking Away

This is the most critical rule: never leave melting wax unattended. The water in a double boiler can evaporate completely, causing the wax to scorch and potentially ignite. A thermostat on a crockpot could fail. You must always be present to monitor the process.

Mistake #2: Using Direct Heat

Never place a pot of beeswax directly on a stovetop burner or use a microwave. These methods provide intense, uneven heat that makes temperature control nearly impossible and dramatically increases the risk of a fire.

Mistake #3: Ignoring the Thermometer

Don't guess the temperature. Use an infrared or candy thermometer to ensure the wax stays in the safe zone of 155°F to 175°F (68°C to 79°C). This protects both you and the quality of your wax.

Making the Right Choice for Your Goal

Your approach should be guided by your specific project and setup.

- If you are a beginner or melting small batches: Use the double boiler method for its simplicity and excellent control.

- If you are melting larger quantities of wax: Invest in a dedicated crockpot to maintain a stable, low temperature for extended periods.

- If your priority is preserving the wax's natural color and aroma: Use a thermometer vigilantly and keep the temperature as low as possible while still achieving a liquid state.

- For all projects: Always wear your PPE, never leave the wax unattended, and keep a fire extinguisher ready.

By treating beeswax with the respect it deserves, you can ensure a safe, efficient, and successful project every time.

Summary Table:

| Safety Precaution | Key Action | Why It's Critical |

|---|---|---|

| Heat Source | Use a double boiler or crockpot | Prevents hot spots & flashpoint ignition (~400°F / 204°C) |

| Temperature Control | Maintain 155°F–175°F (68°C–79°C) | Preserves wax quality and prevents degradation |

| Personal Protection | Wear gloves, goggles, long sleeves | Protects against hot wax splashes and burns |

| Fire Safety | Keep a Class B/ABC fire extinguisher nearby | Water can spread a wax fire; be prepared to extinguish properly |

| Supervision | Never leave melting wax unattended | Allows for immediate response if water evaporates or equipment fails |

Equip Your Apiary with Confidence Using HONESTBEE

Melting beeswax safely is a fundamental skill for any serious beekeeper. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, reliable supplies needed to operate safely and efficiently. From dedicated wax melters and temperature-controlled equipment to essential personal protective gear, our wholesale-focused operations ensure you get the professional tools required to handle beeswax without risk.

Let us help you build a safer, more productive operation. Contact our team today to discuss your specific needs and explore our catalog of trusted beekeeping solutions.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- Why is it important to heat honey slowly and evenly? Preserve Flavor, Nutrients & Value

- At what temperature does honey flow? Preserve Quality with the Perfect 95°F Sweet Spot

- What is melter honey used for? A Low-Cost Ingredient for Bakers and Brewers

- Is it safe to heat crystallized honey? Restore Your Honey's Liquid State Safely

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey