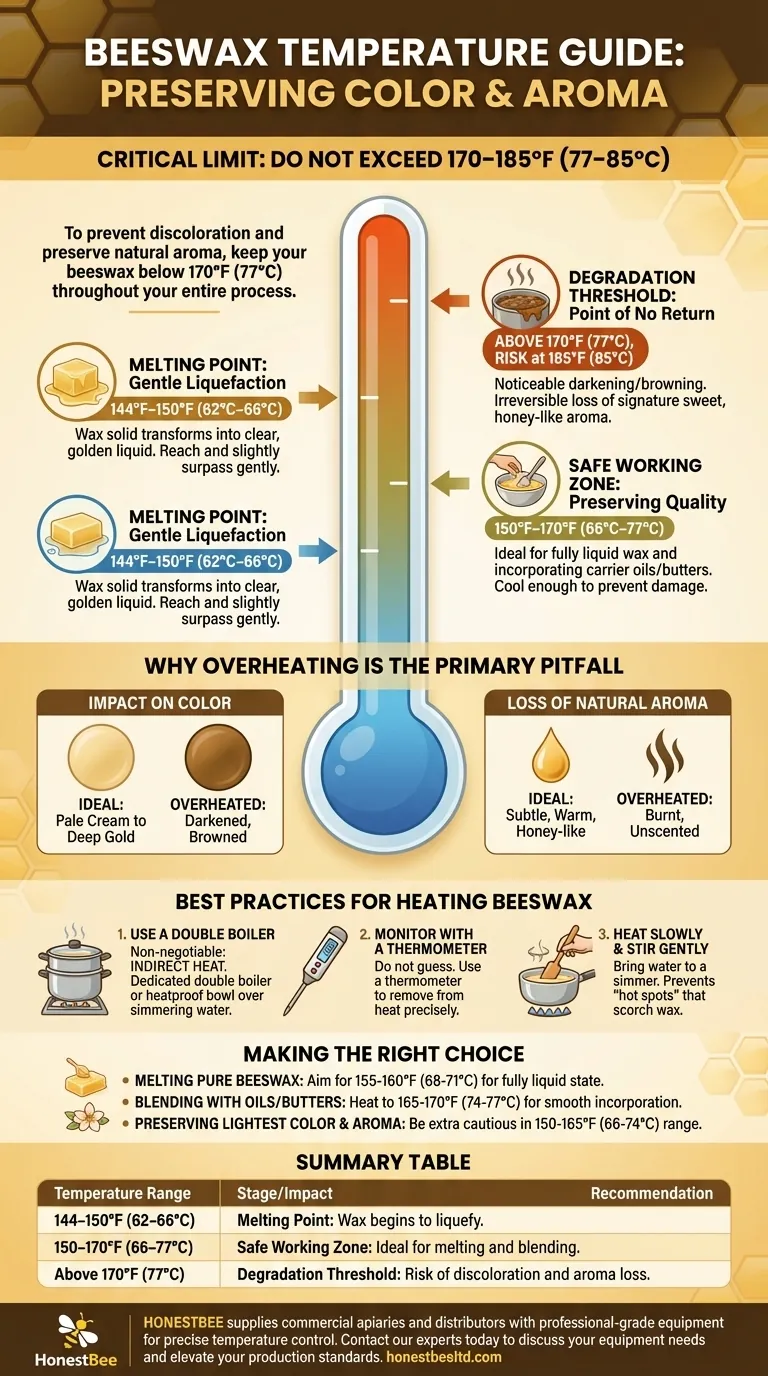

To prevent discoloration and preserve its natural aroma, your beeswax should not be heated above 170–185°F (77–85°C). For the highest quality results, the most reliable and conservative recommendation is to keep the temperature below 170°F (77°C) throughout your entire process.

The key to working with beeswax is not just avoiding a single peak temperature, but maintaining a controlled, low heat. Aim to melt the wax slowly using indirect heat and hold it just above its melting point to preserve its delicate color and aroma.

Understanding Beeswax Temperature Milestones

Heating beeswax is a process with distinct stages. Understanding these temperature milestones is crucial for achieving a professional-quality product without accidental degradation.

The Melting Point: Gentle Liquefaction

Beeswax begins to melt between 144°F and 150°F (62°C and 66°C). At this stage, the solid wax transforms into a clear, golden liquid.

This is the first critical threshold. Your goal is to reach and slightly surpass this point gently, not to rush past it with high heat.

The Safe Working Zone: Preserving Quality

The ideal working temperature for melted beeswax is between 150°F and 170°F (66°C and 77°C).

This range is hot enough to ensure the wax is fully liquid and can easily incorporate other ingredients like carrier oils or butters, but cool enough to prevent damage.

The Degradation Threshold: The Point of No Return

Pushing the temperature beyond 170°F (77°C) introduces risk. As you approach 185°F (85°C), the wax begins to degrade.

This results in a noticeable darkening or browning of the color and the loss of its signature sweet, honey-like aroma. This damage is irreversible.

Why Overheating Is the Primary Pitfall

The unique qualities of beeswax are sensitive. Exposing it to excessive heat causes distinct and undesirable changes.

Impact on Color

The beautiful natural color of beeswax, ranging from pale cream to deep gold, comes from pollen and propolis. High heat effectively "burns" these delicate organic compounds, causing the wax to darken and turn brown.

Loss of Natural Aroma

The subtle, warm scent of beeswax is one of its most valued characteristics. This aroma comes from volatile compounds from honey and flowers. Overheating causes these compounds to evaporate, leaving the wax with a burnt or unscented smell.

Best Practices for Heating Beeswax

The primary cause of overheating is improper technique. Direct heat is the most common mistake and should always be avoided.

Use a Double Boiler

The non-negotiable rule for melting beeswax is to use indirect heat. A dedicated double boiler or a simple heatproof bowl set over a saucepan of simmering water provides gentle, even heating that is easy to control.

Monitor with a Thermometer

Do not guess the temperature. Use a candy or digital kitchen thermometer to monitor the wax continuously. This allows you to remove it from the heat precisely when it reaches the target range.

Heat Slowly and Stir Gently

Bring the water in your double boiler to a simmer, not a rolling boil. Slow heating prevents localized "hot spots" at the bottom of the container that can scorch the wax before the entire batch has even melted.

Making the Right Choice for Your Goal

Your target temperature depends on your specific application. Use the following guidelines to ensure success.

- If your primary focus is simply melting pure beeswax for pouring: Aim for a temperature just above its melting point, around 155-160°F (68-71°C), to ensure it's fully liquid.

- If your primary focus is blending beeswax with other oils or butters: Heat your beeswax toward the top of the safe zone, around 165-170°F (74-77°C), to ensure all ingredients melt and incorporate smoothly.

- If your primary focus is preserving the lightest color and strongest natural aroma: Be extra cautious by working in the 150-165°F (66-74°C) range, removing the wax from heat the moment it is fully melted.

Controlling the temperature is the single most important step to guaranteeing the quality and integrity of your final beeswax product.

Summary Table:

| Temperature Range | Stage/Impact | Recommendation |

|---|---|---|

| 144–150°F (62–66°C) | Melting Point | Wax begins to liquefy. |

| 150–170°F (66–77°C) | Safe Working Zone | Ideal for melting and blending. |

| Above 170°F (77°C) | Degradation Threshold | Risk of discoloration and aroma loss. |

Ready to produce high-quality beeswax products consistently? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the reliable, professional-grade equipment needed for precise temperature control. From durable double boilers to accurate thermometers, our wholesale-focused operations ensure you have the right tools to protect your beeswax's integrity. Contact our experts today to discuss your equipment needs and elevate your production standards.

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What kinds of wax can be melted with a double boiler? Best Safe Methods for Beeswax, Soy, and Paraffin

- How does a solar melter work to process beeswax? The Eco-Friendly Way to Pure Wax

- What are the optimal storage conditions and expected shelf life for processed beeswax? Ensure Indefinite Wax Purity

- What are some alternative methods for melting beeswax? Safely Melt Wax with Slow Cookers & Solar Melters

- What are the key features of the Solar Wax Melter? Efficient, Sustainable Wax Rendering

- What are the operational advantages of using submerged beeswax extraction equipment? Maximize Yield and Reduce Labor

- What is the distillation method for extracting beeswax? Efficient Steam Processing for Pure Results

- What is the solar wax melting process? Harness Free Solar Energy to Purify Beeswax