First and foremost, honey cappings are an incredibly valuable byproduct of your harvest, containing a significant amount of both honey and pure beeswax. The primary goal is to separate these two resources so that nothing is wasted. You can achieve this by draining, spinning, washing, or allowing the bees to clean the cappings for you before melting the remaining wax.

Your approach to handling cappings comes down to a single choice: how you want to separate the residual honey from the valuable wax. Once separated, both components can be put to excellent use, ensuring you utilize every part of your harvest.

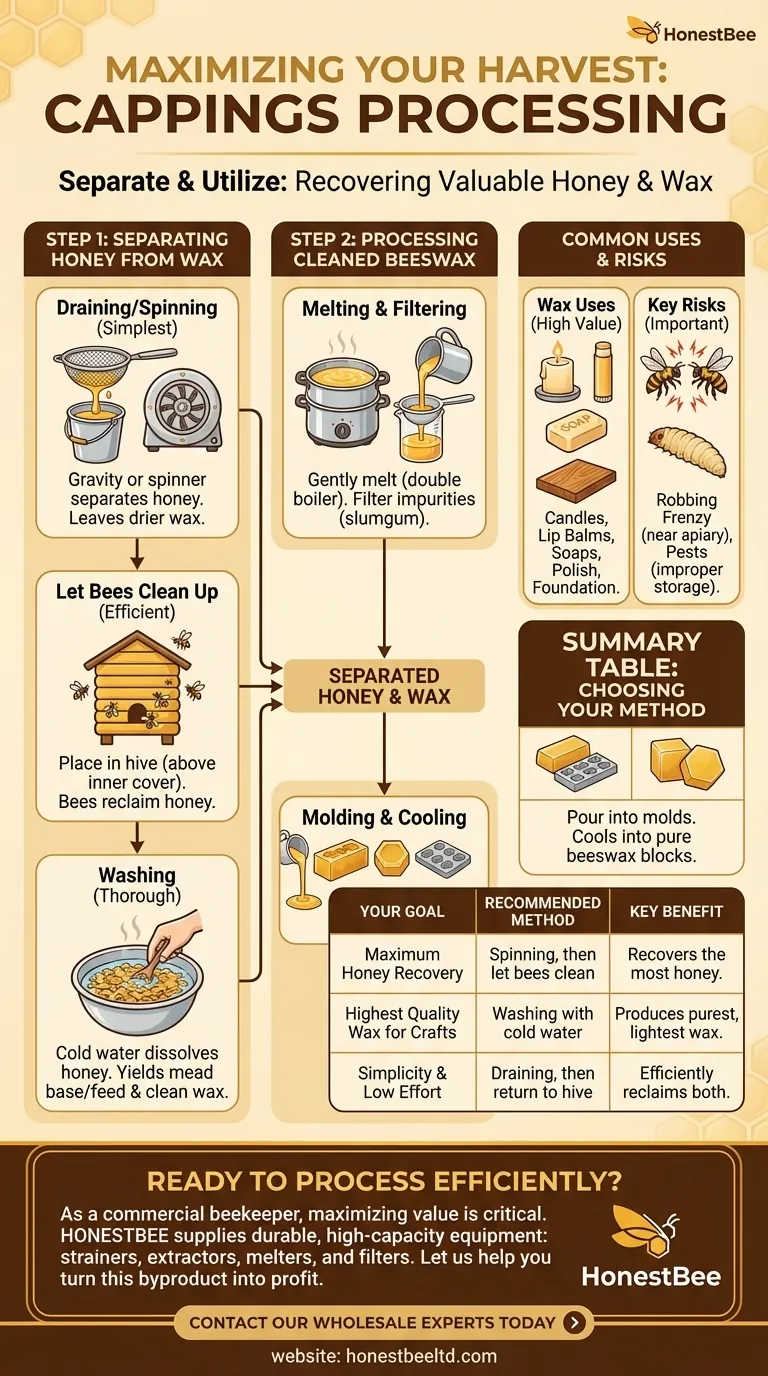

The First Step: Separating Honey from Wax

After uncapping your frames, you are left with "wet" cappings—a mixture of beeswax and a substantial amount of honey. Your first task is to reclaim that honey.

Method 1: Draining or Spinning

The simplest method is to place your cappings in a container with a mesh or screen bottom, such as a dedicated cappings strainer or even a food-grade bucket with a hole and a filter.

Gravity will slowly pull the honey down, leaving you with drier wax. This process can be accelerated significantly if you have an extractor that can spin the cappings.

Method 2: Letting the Bees Clean Up

Many beekeepers return the drained cappings to the hive. Place them in a super above the inner cover, allowing the bees to access them through the hole.

The bees will meticulously carry every last drop of honey down into the main hive. This is an efficient way to recover the honey and feed it back to the colony.

Method 3: Washing the Cappings

For a more thorough separation, you can wash the cappings in water. Use cold water, as it dissolves the honey without melting or damaging the wax.

This honey-water mixture cannot be stored as honey, but it makes an excellent base for mead or can be used as a supplementary feed for your bees. The washed wax is then ready for drying and rendering.

Processing Your Cleaned Beeswax

Once the honey has been removed, you are left with clean, pure beeswax. The next step is to render it into a usable form.

Melting and Filtering

The most common method is to use a double boiler to gently melt the wax. Melting the wax directly over a heat source can scorch it and poses a fire risk.

Once melted, carefully pour the liquid wax through a fine filter, like cheesecloth or a paint strainer, to remove any impurities or debris from the hive (often called "slumgum").

The filtered wax can then be poured into molds—silicone baking molds are a popular choice—to cool and harden into clean blocks or bricks.

Common Uses for Rendered Wax

High-quality beeswax from cappings is prized for its purity and light color. It is perfect for creating products like candles, lip balms, soaps, and furniture polish.

Within beekeeping, it can be used to coat new plastic foundation to encourage acceptance or traded to suppliers to be made into new wax foundation sheets.

Understanding the Trade-offs and Risks

While processing cappings is straightforward, there are important considerations to ensure the health of your colony and the quality of your products.

The Risk of Robbing

Placing wet cappings or frames near the apiary can incite a "robbing frenzy," where bees from your hives (and others) aggressively try to steal the exposed honey. This can lead to fighting and the weakening of colonies.

If you let your bees clean the cappings, always do so inside the hive, above the inner cover, to prevent triggering this behavior.

Pest Attraction

If you choose to store your cappings before processing, keep them in a sealed, airtight container in a cool, dark place.

Improperly stored cappings can attract pests like wax moths and hive beetles, which can quickly ruin your valuable wax.

Effort vs. Reward

Washing cappings yields the cleanest wax but requires more steps and leaves you with honey-water instead of pure honey. Draining is less work but may leave more residual honey in the wax. Choose the method that best fits your goals and available time.

Making the Right Choice for Your Goal

Your strategy for handling cappings should align with your primary objective.

- If your primary focus is maximum honey recovery: Use a spinner or a long draining period, then let the bees clean up the rest.

- If your primary focus is the highest quality wax for crafts: Wash the cappings thoroughly before melting and filtering to produce the purest, lightest-colored beeswax.

- If your primary focus is simplicity and low effort: Drain the cappings for a few days, then return them to the strongest hive for a final cleanup.

By properly processing your cappings, you honor the work of your bees and ensure that no part of their incredible effort goes to waste.

Summary Table:

| Your Goal | Recommended Method | Key Benefit |

|---|---|---|

| Maximum Honey Recovery | Spinning, then let bees clean | Recovers the most honey for your harvest |

| Highest Quality Wax for Crafts | Washing with cold water | Produces the purest, lightest-colored beeswax |

| Simplicity & Low Effort | Draining, then return to hive | Efficiently reclaims both resources with minimal work |

Ready to Process Your Harvest Efficiently?

As a commercial beekeeper or distributor, maximizing the value of every harvest is critical to your bottom line. HONESTBEE supplies the durable, high-capacity equipment you need—from cappings strainers and extractors to wax melters and filters—to process cappings efficiently at scale.

Let us help you turn this valuable byproduct into pure profit. Contact our wholesale experts today to discuss the best equipment solutions for your apiary's specific needs.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What are the key tools needed for the uncapping process? A Guide to Efficient Honey Harvesting

- What are the methods of uncapping honey? A Guide to Tools for Efficient Harvests

- What specialized tools are used for uncapping and straining honey? Professional Gear for Efficient Harvesting

- What workflow considerations can improve the efficiency of uncapping honey frames? Boost Your Honey Harvest Speed

- What is the function of high-performance automatic uncapping devices? Streamline Your Honey Extraction Efficiency

- What are the specific applications of uncapping equipment in a honey processing line? Boost Your Extraction Efficiency

- What role does a chain-type feeding device play in industrial honey uncapping systems? Optimize Your Honey Production

- What is the role of the mechanized honey uncapping machine in large-scale extraction? Boost Your Industrial Efficiency