Ultimately, the choice comes down to the product's physical nature. Horizontal Form Fill Seal (HFFS) machines are better suited for products that are delicate, unstable, sticky, or viscous. Unlike their vertical counterparts, HFFS systems provide the controlled handling necessary for items that cannot be simply dropped into a bag.

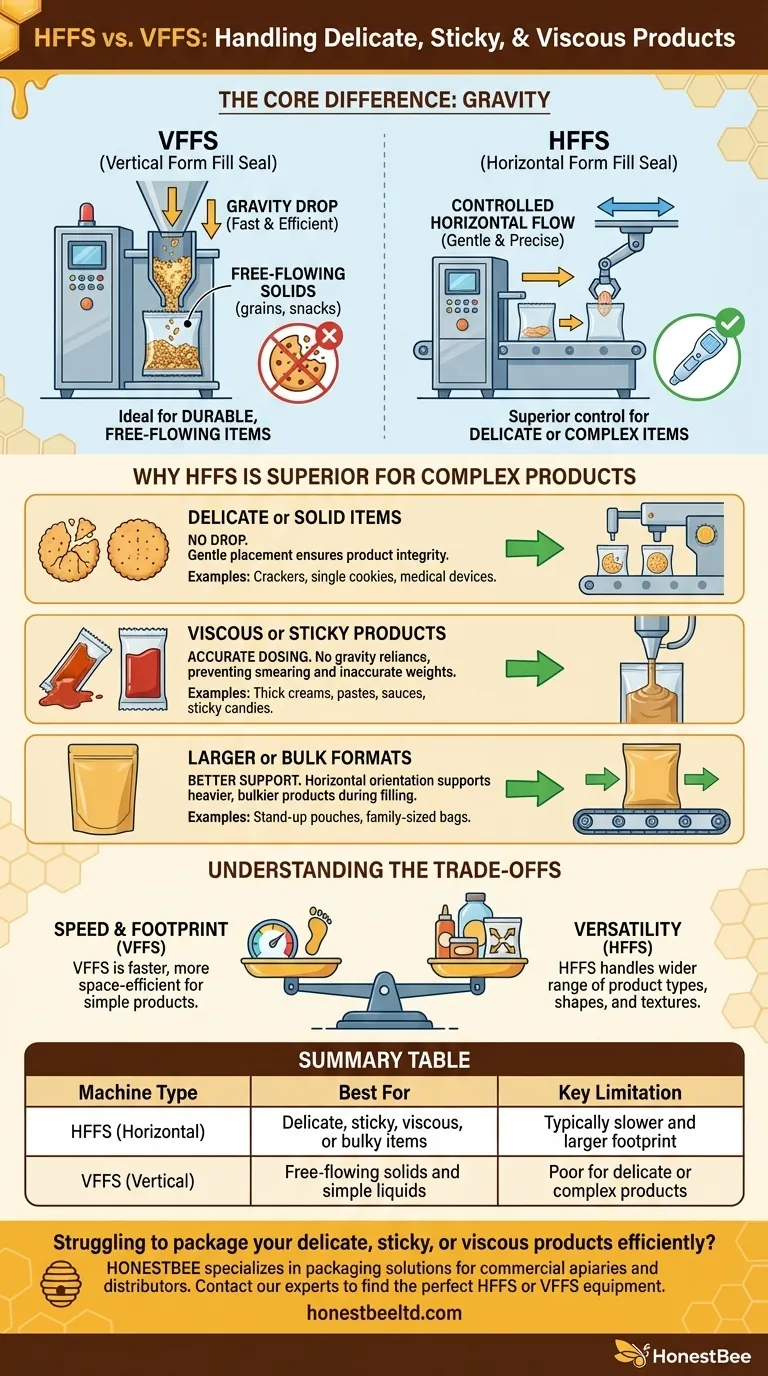

The core difference is gravity. Vertical (VFFS) machines leverage gravity for high-speed filling of free-flowing products, while Horizontal (HFFS) machines operate on a level plane, offering superior control for delicate or complex items that require careful placement.

The Core Difference: Horizontal vs. Vertical Operation

The names "Horizontal Form Fill Seal" and "Vertical Form Fill Seal" describe the fundamental orientation in which the machines operate. This orientation dictates which products they can handle efficiently.

How VFFS Machines Work

VFFS machines operate vertically. A roll of film is formed into a tube, the bottom is sealed, and the product is dropped from above using gravity. Once filled, the top is sealed and the bag is cut.

This process is extremely fast and efficient for the right kind of product. It is ideal for durable, free-flowing items that can withstand a drop.

How HFFS Machines Work

HFFS machines work on a horizontal plane. The pouch is formed or fed onto a conveyor, moves to a filling station, is filled from the side or top, and then moves to be sealed.

This horizontal movement allows for much gentler and more precise handling. The product doesn't need to be dropped, which opens up a wider range of packaging possibilities.

Why HFFS Is Superior for Complex Products

The controlled, horizontal process of an HFFS machine makes it the clear choice for several challenging product categories that are difficult for VFFS systems.

Handling Delicate or Solid Items

Products that could be damaged by a drop, such as crackers, single cookies, or medical devices, can be gently placed into an open pouch on an HFFS line.

This careful placement ensures product integrity and presentation, which is impossible in a gravity-fed vertical system.

Managing Viscous or Sticky Products

Thick creams, pastes, sauces, or sticky candies do not flow predictably with gravity. Filling these with a VFFS machine can lead to inaccurate weights and product smearing in the seal area, causing faulty packages.

HFFS machines use specialized dosing systems that can accurately fill these challenging products into the pouch without relying on gravity, ensuring a clean seal.

Accommodating Larger or Bulk Formats

While VFFS machines excel at smaller, single-serve pouches like chip bags, HFFS machines are often better equipped to handle larger stand-up pouches or family-sized bags.

The horizontal orientation provides better support for heavier, bulkier products during the filling and sealing process.

Understanding the Trade-offs

Neither machine is universally better; they are engineered for different purposes. The decision involves balancing speed, versatility, and product characteristics.

The Speed and Footprint of VFFS

For simple, granular products like coffee, sugar, or snacks, a VFFS machine is typically faster and more space-efficient. Its vertical design gives it a smaller footprint on the factory floor.

The Versatility of HFFS

HFFS machines offer far greater versatility. They can handle a much wider array of product types, shapes, and textures, from solid blocks to thick liquids, making them a more flexible long-term asset for companies with diverse product lines.

Making the Right Choice for Your Product

To select the correct machine, analyze your product's core characteristics and your primary packaging goal.

- If your product is a free-flowing solid or simple liquid (like grains, powders, or snacks): A VFFS machine is the most efficient and cost-effective choice.

- If your product is delicate, sticky, viscous, or requires careful placement (like a baked good, a thick sauce, or a medical kit): An HFFS machine provides the necessary control and gentle handling.

- If you are packaging larger formats or require a stand-up pouch with a zipper: An HFFS machine is generally better suited for these more complex packaging styles.

Choosing the right technology begins with understanding how your product behaves during the filling process.

Summary Table:

| Machine Type | Best For | Key Limitation |

|---|---|---|

| HFFS (Horizontal) | Delicate, sticky, viscous, or bulky items | Typically slower and larger footprint |

| VFFS (Vertical) | Free-flowing solids and simple liquids | Poor for delicate or complex products |

Struggling to package your delicate, sticky, or viscous products efficiently?

HONESTBEE specializes in providing commercial apiaries and beekeeping equipment distributors with the right packaging solutions. Whether you need to package honey, creams, or delicate wax products, we can help you select the optimal HFFS or VFFS equipment to protect your product integrity and boost your packaging line's efficiency.

Contact our experts today to discuss your specific needs and find the perfect packaging machine for your operation.

Visual Guide

Related Products

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Automatic In-Line Flat Surface Labeling Machine

- Professional Durable Customizable Blister Packing Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

People Also Ask

- What is the purpose of induction sealing in honey packaging? Ensure Quality & Build Consumer Trust

- How does an induction sealing machine work? Enhance Honey Packaging with Hermetic Seals & Tamper Evidence

- What is the function of a sealing machine? Protect Product Integrity with Airtight Heat & Pressure Seals

- How does a bottle sealing machine work? Ensure Tamper-Evident, Hermetic Seals for Your Products

- What role do high-barrier sterile packaging and automatic induction sealing equipment play in honey safety management?