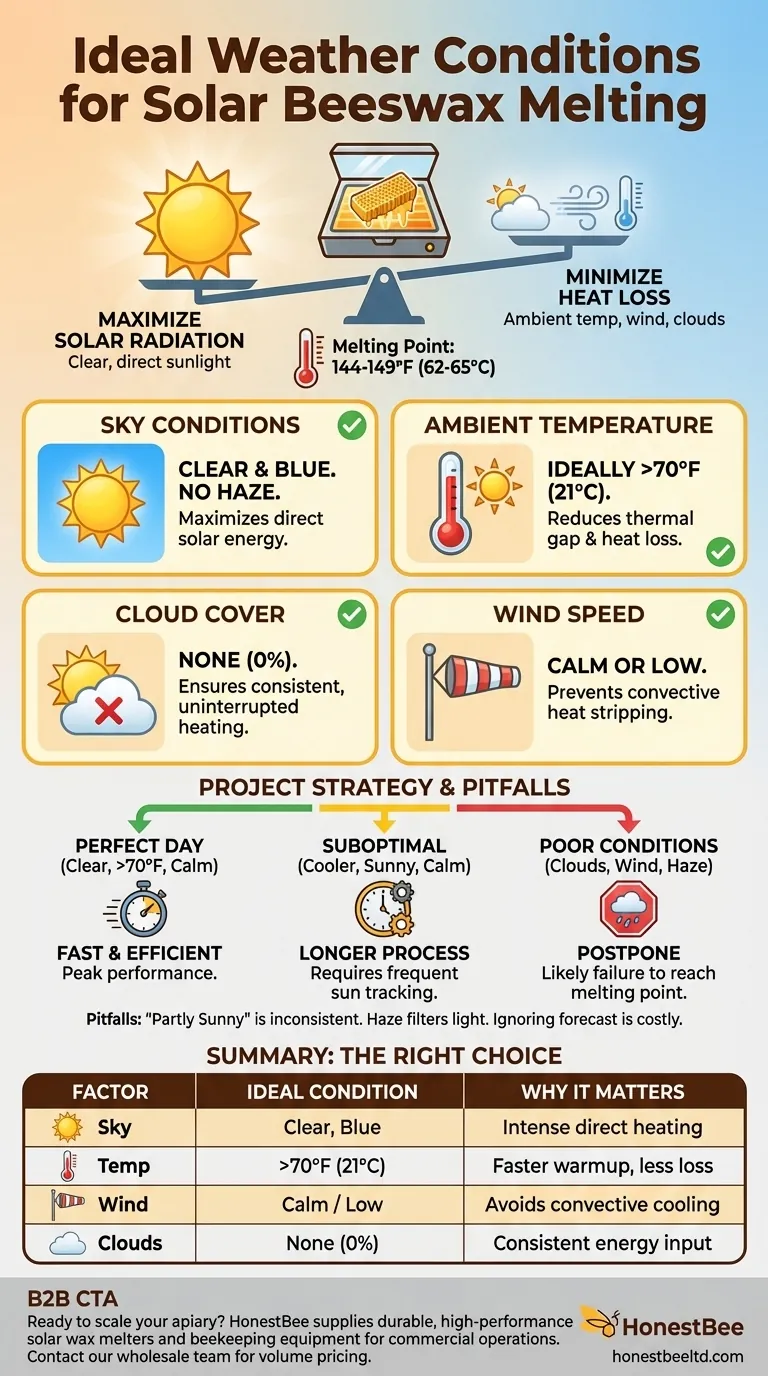

To successfully melt beeswax in a solar oven, you need a clear, warm, and sunny day. The effectiveness of the process hinges on maximizing direct solar energy while minimizing heat loss, making weather the single most critical factor for success.

The ideal conditions are less about just "heat" and more about maximizing uninterrupted solar radiation. A warm, sunny, and calm day allows your oven to absorb energy faster than it loses it to the surrounding environment, which is the fundamental principle required to reach the melting point of beeswax.

The Core Components of Ideal Weather

A solar oven works by converting light into heat. To melt beeswax, which has a melting point of approximately 144-149°F (62-65°C), the oven must consistently absorb more energy than it loses.

Maximizing Solar Radiation (Direct Sunlight)

The primary driver of your solar oven is direct sunlight. The sky should be clear and blue, not hazy or white.

This is why the time of day and year are also crucial. The sun is most powerful between late morning and early afternoon, when it is highest in the sky.

The Role of Ambient Temperature

A higher outside air temperature gives your oven a significant head start. It reduces the temperature difference between the inside of the oven and the outside air.

This smaller temperature gap means the oven loses heat to the environment more slowly, allowing it to reach and maintain the necessary melting temperature much more efficiently.

The Impact of Cloud Cover

Clouds are the biggest obstacle to solar cooking. Even thin, intermittent clouds can dramatically reduce the amount of solar energy reaching your oven.

Each time a cloud passes, the temperature inside the oven will begin to drop. A consistently overcast sky will almost certainly prevent the beeswax from ever reaching its melting point.

The Hidden Factor: Wind Speed

Wind is a critical but often overlooked variable. It strips heat from the exterior of your solar oven through a process called convection.

A windy day, even if it is sunny and warm, can prevent your oven from getting hot enough. The constant cooling effect of the wind can overpower the heating effect of the sun.

Common Pitfalls to Avoid

Understanding what doesn't work is as important as knowing what does. Many failed attempts can be traced back to underestimating the impact of suboptimal conditions.

"Partly Sunny" Is Deceptive

A "partly sunny" forecast often means inconsistent heating. While you might see some melting during sunny periods, the wax may begin to re-solidify during cloudy intervals, dramatically extending the time required.

Haze vs. Clouds

A hazy or milky-looking sky, while technically not cloudy, still filters and scatters sunlight. This significantly reduces the intensity of the solar radiation reaching your oven, leading to poor performance.

Ignoring the Forecast

Starting a project on a promising morning only to have clouds roll in by noon is a common mistake. Always check the forecast for the entire day to ensure you have a long enough window of clear skies.

Making the Right Choice for Your Project

Use this guidance to plan your beeswax melting for maximum efficiency and success.

- If your primary focus is speed and efficiency: Wait for a perfect day with a forecast of clear, blue skies, temperatures above 70°F (21°C), and low wind.

- If you are working with less-than-ideal conditions: On a cooler (but still sunny and calm) day, expect the process to take significantly longer and be prepared to adjust your oven's position frequently to track the sun.

- If the forecast includes significant cloud cover or high winds: Postpone your project. These conditions are the most common causes of failure and will likely prevent your oven from reaching the necessary temperature.

Ultimately, your success depends on choosing a day where the sun's energy input decisively wins the battle against heat loss.

Summary Table:

| Weather Factor | Ideal Condition | Why It Matters |

|---|---|---|

| Sky Conditions | Clear, blue sky | Maximizes direct solar radiation for intense heating. |

| Ambient Temperature | Above 70°F (21°C) | Reduces heat loss, allowing the oven to reach melting point faster. |

| Wind Speed | Calm or low wind | Prevents convective heat loss from the oven's exterior. |

| Cloud Cover | None (0% cloud cover) | Ensures consistent, uninterrupted solar energy input. |

Ready to upgrade your beekeeping operation? Melting wax efficiently is just one part of a successful harvest. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations. From solar wax melters to full hive management systems, we provide the reliable tools you need to scale your productivity.

Contact our wholesale team today to discuss your equipment needs and volume pricing.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield

- How do steam wax melting machines support the biological control of Varroa mites? Stop Parasite Spread and Recover Wax

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency

- What is the role of beeswax processing equipment? Maximize Your Apiary Profit Through Full Resource Utilization