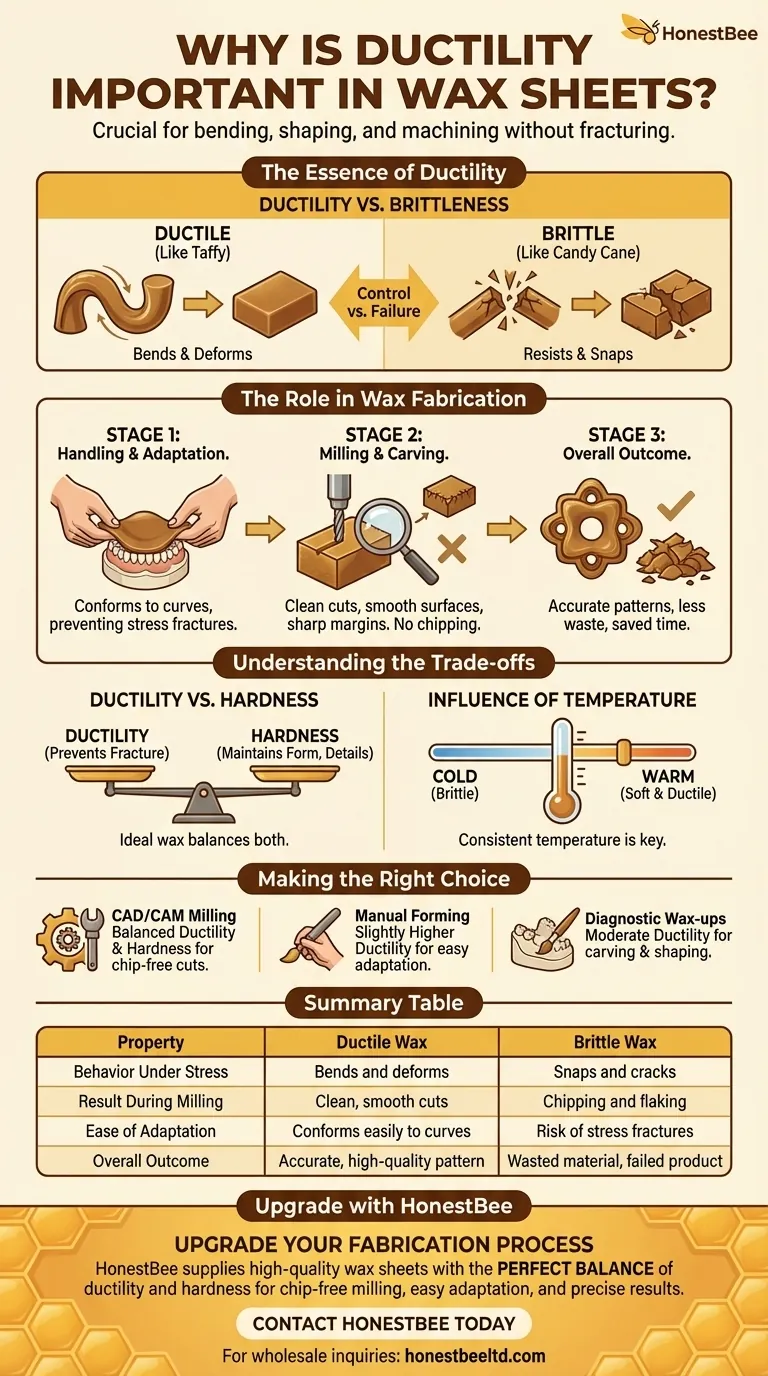

In essence, ductility is the property that allows a wax sheet to be bent, shaped, and machined without fracturing. This quality is crucial because it ensures the wax remains pliable and easy to work with, especially during critical fabrication processes like milling, where brittle materials would chip or break.

The core issue is one of control versus failure. A ductile wax can be precisely manipulated into complex forms, while a brittle wax will crack under stress, leading to wasted material, lost time, and inaccurate results.

The Role of Ductility in Wax Fabrication

To understand why ductility is so important, we must first define it in this context. It is a material's ability to deform under tensile stress—to be stretched or bent—without breaking.

Ductility vs. Brittleness: A Core Distinction

Think of the difference between pulling on a piece of taffy and bending a candy cane.

The taffy is ductile. It stretches and deforms, allowing you to shape it. The candy cane is brittle. It resists deformation until it suddenly snaps. In fabrication, you need your wax to behave like taffy, not a candy cane.

Impact on Handling and Adaptation

Even before machining, ductility is critical. When adapting a wax sheet to a model, such as a dental cast or a jewelry pattern, the material must bend and conform to intricate curves.

A lack of ductility would cause stress fractures or cracks to form as you press the wax into place, compromising the integrity of the pattern from the very beginning.

The Critical Moment: Milling and Carving

The most significant test of ductility comes during subtractive manufacturing, like milling with a CAD/CAM system or carving by hand.

A high-speed bur exerts immense localized stress on the wax. A ductile wax will carve away cleanly, producing smooth surfaces and sharp margins. The material deforms and "cuts" as intended.

A brittle wax, by contrast, will chip and flake at the edge of the cutting tool. This results in rough surfaces, inaccurate anatomy, and a failed end product.

Understanding the Trade-offs

While ductility is essential, it must be balanced with other material properties. An excessive focus on ductility at the expense of everything else can create new problems.

Ductility vs. Hardness

The primary trade-off is with hardness. A wax that is too ductile may also be too soft.

A soft wax might not hold fine details, could distort under its own weight, or become sticky and difficult to handle. The ideal wax has enough ductility to prevent fracture but enough hardness to maintain its form and allow for crisp, precise detailing.

The Influence of Temperature

Ductility in wax is highly dependent on temperature. A wax that is perfectly ductile at room temperature can become brittle if it gets too cold.

Conversely, a small increase in temperature can significantly increase its ductility, but also its softness. Maintaining a consistent working temperature is key to predictable results.

Making the Right Choice for Your Goal

The ideal level of ductility depends entirely on your application and fabrication method.

- If your primary focus is CAD/CAM milling: Seek a wax specifically formulated for milling that balances ductility with a higher hardness to ensure chip-free cutting and precise margins.

- If your primary focus is manual forming and adapting: You may prefer a slightly more ductile wax that conforms easily to complex shapes with minimal risk of cracking.

- If your primary focus is diagnostic wax-ups: A wax with moderate ductility and the ability to be carved without chipping is ideal, as it must withstand both adaptation and detailed shaping.

Ultimately, viewing ductility as a key performance indicator allows you to select the right material to successfully translate a digital or mental design into a physical form.

Summary Table:

| Property | Ductile Wax | Brittle Wax |

|---|---|---|

| Behavior Under Stress | Bends and deforms | Snaps and cracks |

| Result During Milling | Clean, smooth cuts | Chipping and flaking |

| Ease of Adaptation | Conforms easily to curves | Risk of stress fractures |

| Overall Outcome | Accurate, high-quality pattern | Wasted material, failed product |

Upgrade your fabrication process with wax sheets engineered for superior performance.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality wax sheets that offer the perfect balance of ductility and hardness. Our products are formulated to ensure chip-free milling, easy adaptation, and precise results, saving you time and reducing material waste.

Contact HONESTBEE today to discuss your wholesale needs and discover how our reliable beekeeping supplies can enhance your operations.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

People Also Ask

- Why should honeycomb foundations be placed in sealed containers after fumigation? Lock in Efficacy & Prevent Pests

- What is the main drawback of foundationless beekeeping? The Critical Risk of Unmanageable Cross-Comb

- What are the disadvantages of making foundation sheets with a thick base? Boost Hive Efficiency and Wax Hygiene

- How can beekeepers correct 'cross-combing' in a foundationless hive? A Step-by-Step Repair Guide

- Why is the regular replacement of foundation wax necessary? Boost Hive Health and Honey Production

- What is the primary purpose of using worker-sized wax foundations in Varroa mite resistance screening? Enhance Research

- What is a foundation in a beehive frame? Choosing Between Wax and Plastic for Hive Success

- What steps are involved in installing wax foundation sheets? A Guide to Secure, Straight Comb Building