A honey warming cabinet is the professional standard for reversing crystallization because it applies gentle, precisely controlled heat over an extended period. This process safely re-liquefies granulated honey, protecting the delicate enzymes, aromas, and flavors that are easily damaged by faster, more intense heating methods.

The core challenge isn't just melting crystallized honey; it's doing so without destroying its beneficial properties and unique flavor profile. A warming cabinet provides the slow, consistent, and low-temperature environment required to safely return honey to a liquid state, a task that rapid heating simply cannot achieve without causing damage.

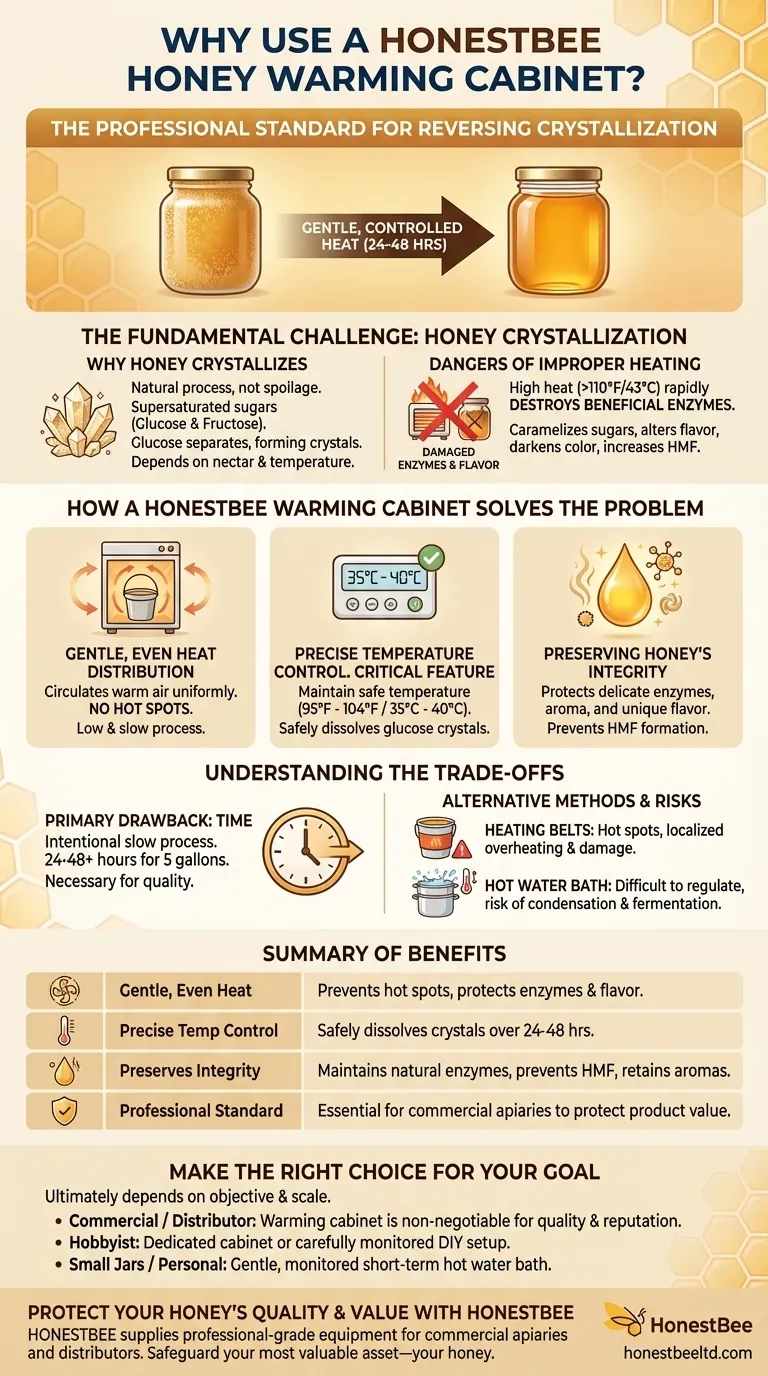

The Fundamental Challenge: Honey Crystallization

Why Honey Crystallizes

Crystallization, or granulation, is a completely natural process and is not a sign of spoilage. It occurs because honey is a supersaturated solution of sugars, primarily glucose and fructose.

Over time, the glucose tends to separate from the water in the honey, forming tiny crystals that spread throughout the container. The rate of crystallization depends on the honey's nectar source and storage temperature.

The Dangers of Improper Heating

The goal is to dissolve the glucose crystals back into the solution, but using uncontrolled or excessive heat is destructive.

Applying high heat (above 110°F or 43°C) rapidly destroys beneficial enzymes like diastase and invertase, which are key markers of high-quality, raw honey.

It also caramelizes the sugars, altering the flavor, darkening the color, and significantly increasing the levels of HMF (hydroxymethylfurfural), a chemical compound used to indicate heat damage.

How a Warming Cabinet Solves the Problem

Gentle, Even Heat Distribution

Unlike direct heat sources that create damaging "hot spots," a warming cabinet circulates warm air to heat the entire container uniformly.

This ensures that no part of the honey is overheated while other parts are still solid. It's a low and slow process by design.

Precise Temperature Control

This is the most critical feature. A quality warming cabinet allows you to set and maintain a specific, safe temperature—typically between 95°F and 104°F (35°C and 40°C).

This temperature range is just warm enough to gently dissolve the glucose crystals over 24-48 hours without degrading the honey's chemistry.

Preserving Honey's Integrity

By using low, indirect, and precisely controlled heat, a warming cabinet protects the honey’s most valuable attributes.

It maintains the natural enzyme content, prevents the formation of HMF, and preserves the delicate aromas and flavors that are unique to the honey's floral source.

Understanding the Trade-offs and Alternatives

The Primary Drawback: Time

The greatest strength of a warming cabinet is also its main trade-off. The process is intentionally slow.

Liquefying a five-gallon bucket of fully crystallized honey can take 24 to 48 hours, or even longer. This is the necessary price for preserving quality.

Alternative Methods and Their Risks

While other options exist, they come with significant risks.

Heating belts or bucket warmers can be effective for a single container but can create hot spots against the side of the bucket, leading to localized overheating and damage.

A hot water bath (double boiler) is very difficult to regulate for the long periods required. It also introduces the risk of condensation or water splashing into your honey, which can cause fermentation.

Making the Right Choice for Your Goal

Ultimately, the right tool depends on your objective and the scale of your operation.

- If your primary focus is preserving raw honey quality for sale: A warming cabinet is a non-negotiable investment to protect your product's integrity and your professional reputation.

- If you are a hobbyist managing a few hives: A dedicated cabinet provides peace of mind, but a carefully monitored DIY setup (like an insulated box with a thermostat-controlled heat source) can also work effectively.

- If you only need to liquefy small jars for personal use: A gentle, short-term hot water bath is often sufficient, provided you monitor it closely to ensure the honey itself doesn't overheat.

Controlling the heating process is fundamental to protecting the unique quality and value of your honey.

Summary Table:

| Feature | Benefit |

|---|---|

| Gentle, Even Heat | Prevents hot spots and protects honey's delicate enzymes and flavor profile. |

| Precise Temperature Control (95°F-104°F) | Safely dissolves crystals over 24-48 hours without degrading quality. |

| Preserves Honey Integrity | Maintains natural enzymes, prevents HMF formation, and retains unique aromas. |

| Professional Standard | Essential for commercial apiaries and distributors to protect product value. |

Protect Your Honey's Quality and Value with HONESTBEE

As a commercial apiary or beekeeping equipment distributor, the quality of your honey is your reputation. HONESTBEE supplies the professional-grade honey warming cabinets and beekeeping equipment you need to ensure your product meets the highest standards.

Our wholesale-focused operations are designed to provide reliable, efficient solutions for your business.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs and safeguard your most valuable asset—your honey.

Visual Guide

Related Products

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Stainless Steel Honey Press Wax Press with Tank

- Beeswax Melter for Candle Making Honey Bee Wax Melter

People Also Ask

- What is the purpose of an external heater for the storage tank in a honey drying system? Boost Dehydration Efficiency

- Why must commercial honey thermal processing equipment have high-precision temperature control? Save Your Honey Quality

- How does industrial-grade heat treatment equipment affect the quality of crystalline honey? Mastery Through Control

- What are the benefits of a honey heating tank? Achieve Crystal-Clear, Market-Ready Honey

- How does a honey heating tank preserve the quality of honey? Gentle Heat for Purity & Flavor

- Why is the use of a constant temperature and humidity incubator essential? Control Honeybee Survival Environments

- Why is the placement of temperature sensors critical for honey recrystallizer design? Protect Your Honey's Value

- What types of drums is the honey warming blanket heater compatible with? Versatile Heating for Steel and Poly Drums