You’ve done everything right. The harvest was perfect, the extraction clean, and the honey’s flavor profile is exceptional. But on bottling day, something is wrong. The honey flowing into the jars has a slight cloudiness, dotted with tiny, persistent air bubbles. Weeks later, you get a call from a distributor: a significant portion of the last shipment has started to crystallize on the shelf. The premium product you worked so hard to create is now facing the risk of being sold at a discount.

If this scenario feels painfully familiar, you are not alone.

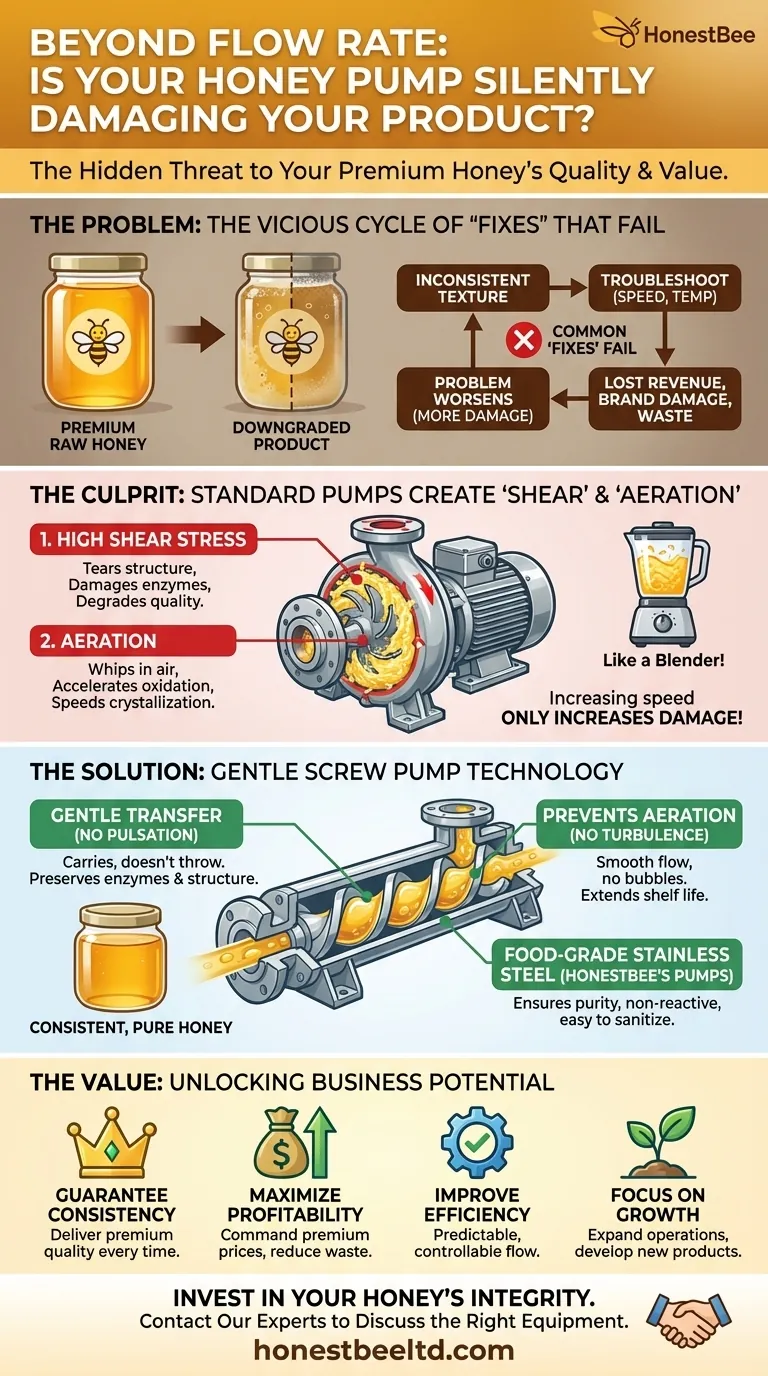

The Vicious Cycle of 'Fixes' That Fail

For many commercial apiaries, inconsistent honey texture and premature crystallization are chronic, frustrating battles. The common response is to troubleshoot the most obvious variables. Maybe you try increasing the pump speed to get through the batch faster, or you install a filtration system to remove the bubbles. Perhaps you even blame the honey's specific floral source or adjust the temperature in the processing room.

While these seem like logical steps, they often make the problem worse or fail to address it at all.

This isn't just a technical headache; it has serious business consequences.

- Lost Revenue: Premium raw honey is downgraded to a lower-value product, directly impacting your profit margins.

- Brand Damage: Inconsistent quality erodes the trust of your distributors and customers, making it harder to command a premium price.

- Operational Waste: Time and resources are spent troubleshooting, re-processing batches, or handling product returns instead of focusing on growth.

The cycle continues because these "solutions" only address the symptoms. The real problem is hidden in plain sight: the very tool you're using to move your honey.

The Real Culprit: It's Not the Honey, It's the 'Shear'

The vast majority of honey quality issues introduced during processing can be traced to one fundamental misunderstanding: the belief that a pump’s only job is to move liquid from point A to point B. In reality, how it moves the honey is critically important.

Many standard pumps (like impeller or gear pumps) operate with a high-speed, churning action. Imagine using a kitchen blender to transfer a delicate sauce. While it moves the liquid, it also violently agitates it. This introduces two destructive forces:

1. High Shear Stress

This is a mechanical force that literally tears and breaks down the honey’s complex structure. It can damage the delicate enzymes and volatile flavor compounds that make your honey unique and valuable. It's an invisible assault that degrades quality at a molecular level.

2. Aeration

The same churning action that creates shear also whips tiny air bubbles into the honey. This is far from harmless. Aeration introduces oxygen, which accelerates oxidation and can alter the flavor. More importantly, these microscopic air bubbles act as nucleation sites, providing the perfect starting points for sugar crystals to form. This dramatically speeds up unwanted crystallization.

This is why turning up your pump speed often backfires. You are essentially turning up the speed on the "blender," subjecting your honey to even more intense shear and aeration, and accelerating the very problems you want to solve.

Designed for Gentleness: How a Screw Pump Solves the Root Problem

To preserve the integrity of honey, you don't need a faster or more powerful pump. You need a gentler one. The solution lies in fundamentally changing the pumping mechanism from a violent churn to a gentle transfer.

This is precisely what a progressive cavity pump, commonly known as a screw pump, is designed to do.

Instead of an impeller, a screw pump uses a helical rotor (the "screw") that turns within a flexible stator. As it rotates, it creates a series of sealed, contained pockets. These pockets trap a specific volume of honey and carry it steadily from the inlet to the outlet without pulsation or agitation.

This design directly counteracts the root causes of damage:

- It Eliminates High Shear: The honey is carried, not thrown. This positive displacement action is incredibly gentle, preserving the delicate enzymes and complex structure that define your product's quality.

- It Prevents Aeration: The smooth, continuous flow creates no turbulence, so air is not whipped into the product. The result is pure, clear honey with a greatly extended shelf life and resistance to crystallization.

- It Ensures Purity: When this gentle mechanism is built from food-grade stainless steel, as HONESTBEE’s pumps are, you also guarantee that nothing leaches into the honey. The material is non-reactive, durable, and easy to sanitize, protecting the purity of your product and your compliance with food safety standards.

A stainless steel screw pump isn't just another piece of equipment. It is a system engineered from a deep understanding of honey's delicate nature, designed to protect its value at every stage.

From Problem-Solving to New Possibilities

When you stop unknowingly damaging your product, you’re not just fixing a problem—you’re unlocking new potential for your business. With a process that protects honey’s integrity, you can:

- Guarantee Consistency: Deliver the same premium quality in every single batch, building a powerful brand reputation that distributors and customers trust.

- Maximize Profitability: Confidently market and sell your honey at the premium price it deserves, knowing its raw, delicate characteristics are perfectly preserved.

- Improve Efficiency: Integrate a predictable, controllable flow into your bottling line, increasing throughput and reducing manual oversight.

- Focus on Growth: Shift your energy from firefighting quality issues to expanding your operations, developing new products, and growing your market share.

Your honey's quality is your most valuable asset. The equipment you use should be its guardian, not its greatest threat. Moving beyond a conventional pump is an investment in the consistency, reputation, and long-term success of your entire operation. If your business depends on delivering a premium product, let's ensure your process is built to protect it. Contact Our Experts to discuss how the right equipment can solve your processing challenges and safeguard your brand.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional Thermostatic Conical Honey Melter

Related Articles

- How Bee Behavior and Weather Dictate Optimal Honey Harvest Times

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability

- The Unseen Battle in Every Honey Bucket: Heat, Time, and Quality

- The Clarity Trap: Why We Heat Honey and What We Lose in the Process

- Heat, Honey, and Haste: The Physics of Preserving Liquid Gold