Choosing the right queen excluder material can significantly impact your beekeeping success. This guide compares galvanized and stainless steel options across three critical factors: corrosion resistance, long-term costs, and hive health compatibility. Whether you're a hobbyist or commercial beekeeper, understanding these differences ensures you invest in equipment that aligns with your apiary’s needs.

Choosing the Best Queen Excluder Material

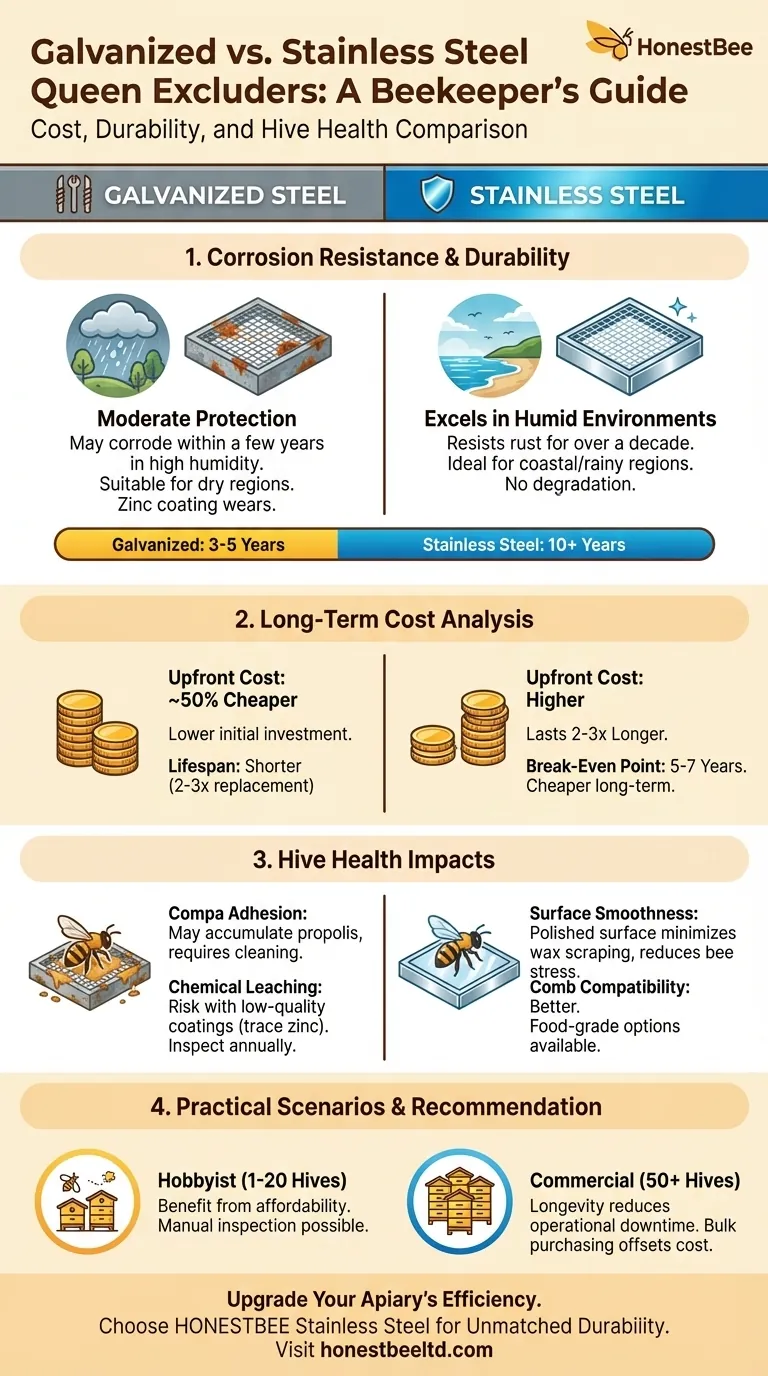

Corrosion Resistance in Humid vs. Dry Climates

Stainless steel excels in humid environments, resisting rust even with prolonged exposure to moisture and hive acids. Beekeepers in coastal or rainy regions report stainless steel excluders lasting over a decade without degradation.

Galvanized steel offers moderate protection but may corrode within a few years in high-humidity areas. The zinc coating wears down over time, especially where bees scrape the surface during routine movement. In arid climates, however, galvanized excluders can perform nearly as well as stainless steel.

Key Takeaway: Prioritize stainless steel for wet climates; galvanized may suffice in dry regions if replaced periodically.

Long-Term Cost Analysis: Initial Price vs. Replacement Frequency

- Upfront Cost: Galvanized excluders cost roughly half as much as stainless steel.

- Lifespan: Stainless steel lasts 2–3 times longer, reducing replacement needs.

- Break-Even Point: Over 5–7 years, stainless steel often proves cheaper due to lower replacement frequency.

For commercial apiaries managing hundreds of hives, stainless steel’s durability translates to lower labor and equipment costs long-term. Hobbyists with fewer hives might prefer galvanized steel’s lower initial investment.

Hive Health Impacts: Bee Safety and Comb Compatibility

Both materials are safe for bees when properly manufactured, but subtle differences matter:

- Surface Smoothness: Stainless steel’s polished surface minimizes wax scraping, reducing bee stress.

- Comb Adhesion: Galvanized excluders may accumulate more propolis, requiring occasional cleaning.

- Chemical Leaching: Low-quality galvanized coatings can release trace zinc, though food-grade options mitigate this risk.

Pro Tip: Inspect galvanized excluders annually for coating wear to prevent metal exposure.

Practical Scenarios for Beekeepers

Small-Scale Hobbyist vs. Commercial Apiary Needs

Hobbyists (1–20 hives):

- Benefit from galvanized steel’s affordability.

- Can manually inspect and replace excluders as needed.

Commercial Beekeepers (50+ hives):

- Stainless steel’s longevity reduces operational downtime.

- Bulk purchasing offsets higher initial costs.

Case Study: Beekeeper Experiences with Material Degradation

A midwestern apiary reported:

- Galvanized excluders required replacement every 3–4 years due to rust.

- Stainless steel excluders showed no corrosion after 8 years, despite harsh winters.

Upgrade Your Apiary’s Efficiency

For commercial beekeepers and distributors, HONESTBEE’s stainless steel queen excluders deliver unmatched durability, ensuring your hives thrive with minimal maintenance. Explore our wholesale-focused catalog for equipment built to withstand the demands of large-scale beekeeping.

Products You Might Be Looking For:

Explore wooden queen excluder options

Visual Guide

Related Products

- Professional Plastic Queen Excluder for Modern Beekeeping

- Wooden Queen Bee Excluder for Beekeeping

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

- Premium Wood Framed Metal Wire Queen Bee Excluder

- Metal Queen Bee Excluder for Beekeeping

Related Articles

- Beyond the Gate: The Queen Excluder as a Keystone of Apiary Efficiency

- How to Choose Queen Excluder Materials for Healthier Hives and Higher Yields

- How Queen Excluders Optimize Hive Management: A Beekeeper’s Guide

- How to Choose the Right Queen Excluder for Your Beekeeping Success

- The Unseen Gatekeeper: Why Queen Excluders Are Non-Negotiable for Flow Hives