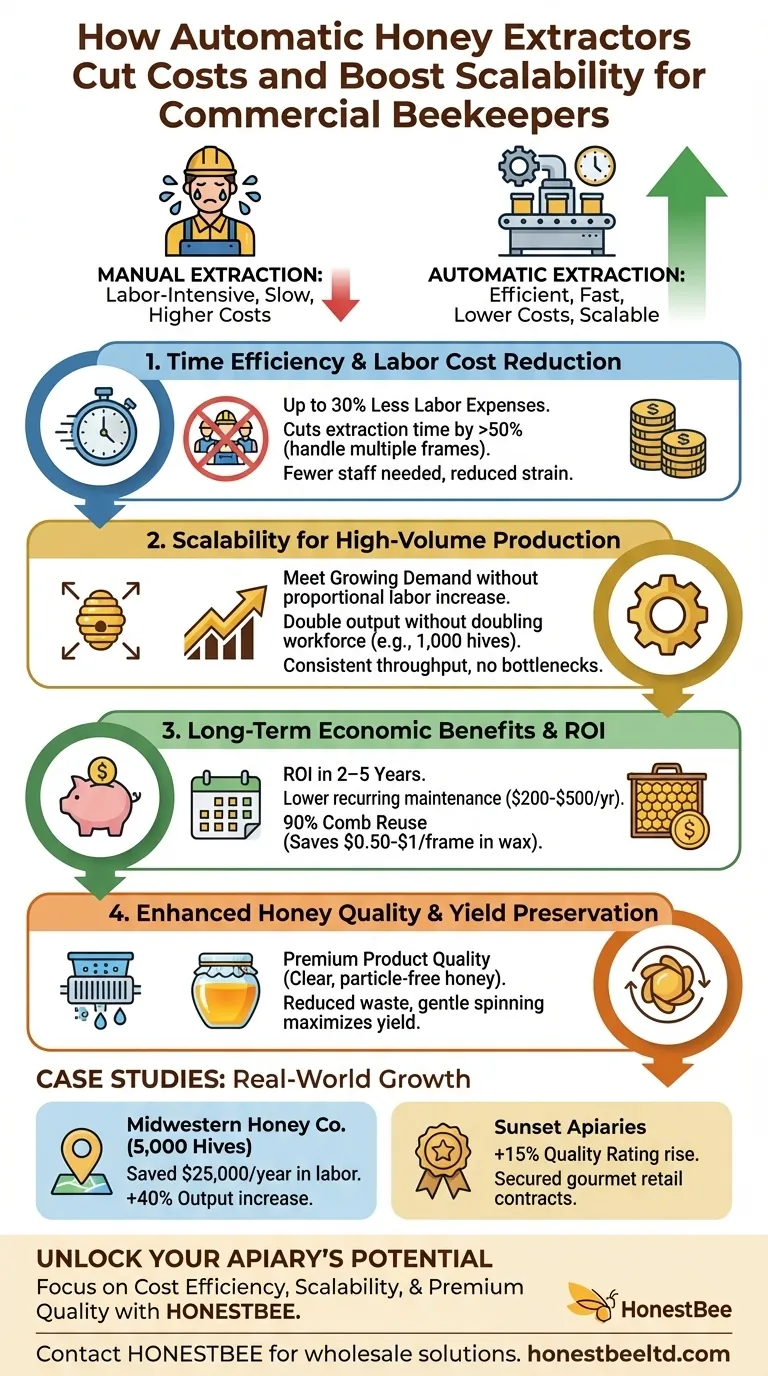

For commercial beekeepers, scaling production while maintaining profitability is a constant challenge. Automatic honey extractors have emerged as a game-changing solution, reducing long-term operational costs by streamlining labor-intensive processes and preserving honey quality. Here’s how automation transforms apiary economics.

Advantages of Automatic Honey Extractors

1. Time Efficiency and Labor Cost Reduction

Manual honey extraction demands significant physical effort and time—tasks like uncapping frames, spinning combs, and filtering honey can occupy hours per harvest. Research shows automation reduces labor expenses by up to 30%, allowing teams to focus on higher-value tasks like hive management or market expansion.

Key benefits:

- Faster processing: Automatic extractors handle multiple frames simultaneously, cutting extraction time by over half compared to manual methods.

- Reduced staffing needs: Fewer workers are required for harvesting, lowering payroll costs.

- Ergonomic relief: Eliminates repetitive strain injuries associated with manual spinning.

2. Scalability for High-Volume Production

Automation enables beekeepers to meet growing demand without proportionally increasing labor. For example, a mid-sized apiary processing 1,000 hives annually can double output without doubling its workforce by investing in automatic extractors.

Why scalability matters:

- Consistent throughput: Machines maintain uniform extraction speeds, preventing bottlenecks during peak seasons.

- Adaptability: Modular systems allow incremental upgrades (e.g., adding more drums or filters) as operations expand.

3. Long-Term Economic Benefits and ROI

While automatic extractors require higher upfront investment (typically 2–3× the cost of manual systems), they pay for themselves within 2–5 years through:

- Lower recurring costs: Energy-efficient motors and minimal maintenance (approximately $200–$500 annually) reduce overhead.

- Higher yield retention: Precision extraction preserves comb integrity, enabling bees to reuse 90% of combs—saving $0.50–$1 per frame in wax replacement costs.

4. Enhanced Honey Quality and Yield Preservation

Automatic systems integrate filtration to remove impurities like wax debris and pollen, resulting in:

- Premium product quality: Clear, particle-free honey commands higher market prices.

- Reduced waste: Gentle spinning minimizes comb damage, maximizing usable yield per hive.

5. Case Studies: Apiaries Achieving Growth Through Automation

- Midwestern Honey Co. adopted automation to manage 5,000 hives, reducing labor costs by $25,000/year while increasing output by 40%.

- Sunset Apiaries reported a 15% rise in honey quality ratings after switching to automated filtration, securing contracts with gourmet retailers.

Unlock Your Apiary’s Potential with HONESTBEE

For commercial beekeepers and distributors, HONESTBEE’s automatic honey extractors deliver cost efficiency, scalability, and premium product quality—essential for thriving in competitive markets. Explore our wholesale-focused solutions to transform your honey production today.

Ready to automate your harvest? Contact HONESTBEE to discover equipment designed for your growth.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- How to Extract Honey Sustainably: Maximizing Yield Without Harming Bees

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- How to Choose the Right Honey Extractor for Your Beekeeping Scale

- The Physics of a Perfect Harvest: Why the Honey Extractor Is a Marvel of Efficiency

- Beyond Speed: The Compounding Returns of an Electric Honey Extractor