Honey’s shelf life and quality depend heavily on moisture control—a factor directly influenced by drying technology. For commercial beekeepers and distributors, understanding the relationship between disc speed in honey dryers and spoilage prevention is critical. This article explores the science behind moisture management, the role of disc speed optimization, and real-world applications that ensure premium honey production.

Honey Preservation Science and Modern Drying Technology

Honey’s natural resistance to spoilage stems from its low water content, but even slight deviations in moisture levels can compromise quality. Modern drying technologies, like those from HONESTBEE, address this by fine-tuning disc speed to achieve precise evaporation rates without damaging delicate enzymes or flavor profiles.

The Role of Moisture and Microbial Activity in Honey Spoilage

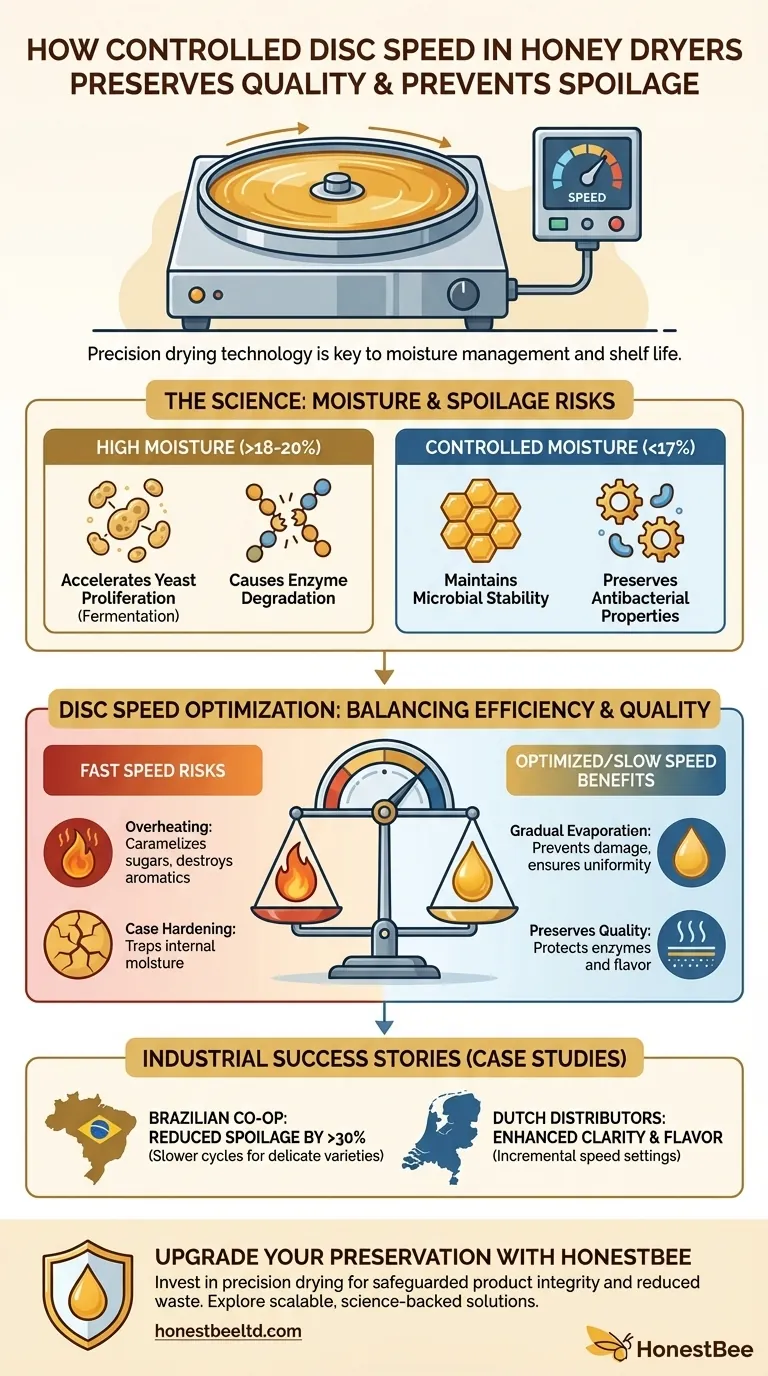

Microbial growth in honey thrives when moisture exceeds certain thresholds:

- Yeast proliferation accelerates above 18–20% water content, leading to fermentation.

- Enzyme degradation occurs when excess moisture breaks down natural preservatives like glucose oxidase.

Research shows that controlled drying mitigates these risks by maintaining moisture levels below 17%, a benchmark for microbial stability. Slow, consistent evaporation—enabled by adjustable disc speeds—ensures uniform drying while preserving honey’s antibacterial properties.

Disc Speed Optimization: Balancing Drying Efficiency and Quality

Disc speed directly impacts two key outcomes:

- Evaporation Rate: Faster speeds increase airflow but risk overheating, which can caramelize sugars or destroy volatile aromatics.

- Uniformity: Slower speeds allow gradual moisture removal, preventing case hardening (surface crystallization trapping internal moisture).

Industrial dryers with variable speed controls, such as those supplied by HONESTBEE, enable beekeepers to adapt to batch-specific needs—like higher initial moisture in raw honeycomb—without sacrificing efficiency.

Industrial Case Studies: Successes in Slow-Drying Honey Processing

Commercial apiaries report measurable improvements when prioritizing disc speed precision:

- A Brazilian cooperative reduced spoilage rates by over 30% after adopting slower drying cycles for delicate floral varieties.

- Dutch distributors noted enhanced clarity and flavor retention in bulk batches dried at incremental speed settings.

These examples underscore how tailored drying preserves both quantity and quality, aligning with HONESTBEE’s mission to equip beekeepers with scalable, science-backed solutions.

Upgrade Your Honey Preservation Today

For commercial apiaries and distributors, investing in precision drying technology means safeguarding product integrity and reducing waste. HONESTBEE’s beekeeping equipment integrates adjustable disc speed controls to meet industry demands—ensuring your honey stays pure, stable, and market-ready.

Explore our wholesale-focused solutions to elevate your honey processing with equipment designed for quality and efficiency.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- How to Clean Your Honey Extractor Safely Without Compromising Honey Quality

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability

- Honey Press vs. Extractor: Why Your Choice Defines Your Apiary's Profitability

- Beyond Purity: How Honey Filtering Machines Engineer Trust at Scale

- The Clarity Trap: Why We Heat Honey and What We Lose in the Process