The Unseen Bottleneck in Commercial Beekeeping

Imagine the scene: a successful harvest. Barrels of rich, fragrant honey stand ready, a testament to a season of hard work. Yet, between this raw bounty and a market-ready product lies a formidable challenge—the problem of variance.

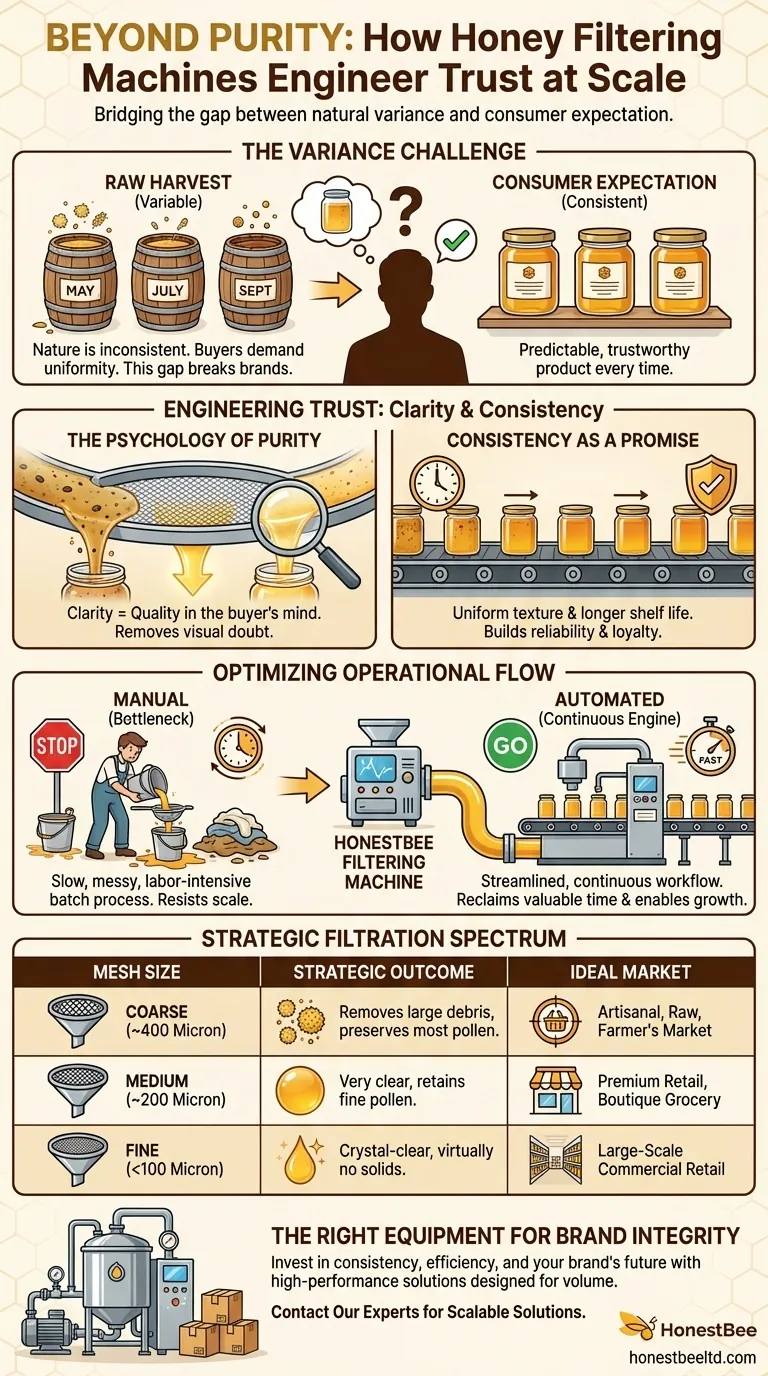

The honey in barrel one, harvested in May, has a slightly different texture and contains different pollen grains than the honey in barrel two, harvested in July. Nature is inconsistent. Consumers, however, are not. They expect, consciously or not, that the jar of honey they buy today will be identical to the one they bought last month.

This gap between natural variation and consumer expectation is where brands are built or broken. Scaling a honey operation isn't just about managing more hives; it's about mastering the system that transforms a variable agricultural product into a predictable, trustworthy consumer good.

Engineering Consumer Trust: The Role of Clarity and Consistency

The core function of a honey filtering machine isn't just "cleaning." It's about standardizing your product to meet a deeply ingrained psychological trigger in the buyer's mind.

The Psychology of Purity

We don't just taste with our tongues; we taste with our eyes first. In the mind of the average consumer, clarity equals quality. A stray wax particle, a bee wing, or a bit of debris, however harmless, introduces a flicker of doubt. It breaks the illusion of a pristine, professional product.

A filtering machine systematically removes these visual imperfections, delivering the crystal-clear aesthetic that reassures customers and builds subconscious trust in your brand's quality control.

Consistency as a Brand Promise

Every single jar is a promise to your customer. By removing suspended solids, a filtering machine ensures a smooth, uniform texture from batch to batch, year to year. This reliability is the bedrock of brand loyalty.

Furthermore, by removing impurities that can act as nucleation points for crystallization or fermentation, proper filtration contributes to a more stable product with a longer shelf life—another crucial component of that promise.

The Physics of Flow: Optimizing Your Operational Engine

For any bulk producer, the greatest enemies are bottlenecks, manual labor, and wasted time. Automation isn't a luxury; it's a necessity for survival and growth.

From Buckets to a Continuous System

Manual filtering—pouring honey through layers of strainers and cloths—is a slow, messy, and labor-intensive batch process. It's a system that actively resists scale.

A honey filtering machine, integrated with pumps and bottlers, transforms your workflow. It creates a smooth, continuous flow from the extractor to the final container. It replaces a chaotic, multi-step process with an elegant, streamlined engine. The increase in throughput isn't incremental; it's transformative.

Reclaiming Your Most Valuable Asset: Time

This newfound efficiency translates directly to your bottom line. It dramatically reduces labor costs, shortens your production cycle, and gives you the capacity to process larger harvests without chaos. You are no longer just a beekeeper; you are the manager of an efficient production system.

Navigating the Filtration Spectrum: A Strategic Decision

The question isn't whether to filter, but how. The machine is a tool, and its use is a strategic choice that defines your product and your target market. Using different filter mesh sizes allows you to customize the final product with precision.

| Mesh Size | Strategic Outcome | Ideal Market |

|---|---|---|

| Coarse (~400 Micron) | Removes large debris (wax, bee parts) while preserving most pollen. | Artisanal, Raw, Farmer's Market |

| Medium (~200 Micron) | Creates a very clear product that still contains fine pollen particles. | Premium Retail, Boutique Grocery |

| Fine (<100 Micron) | Produces a crystal-clear product with virtually no suspended solids. | Large-Scale Commercial Retail |

This level of control empowers you. You can produce ultra-pure honey for a national distributor and a minimally-filtered raw honey for a local health food store, all using the same efficient, scalable system.

The Right Equipment for an Unforgiving Market

A honey filtering machine is more than a piece of hardware. It's an investment in consistency, efficiency, and brand integrity. It’s the bridge between a good harvest and a great business.

For commercial apiaries and distributors, where volume and consistency are non-negotiable, having robust, reliable equipment is paramount. HONESTBEE specializes in supplying wholesale beekeeping equipment, including high-performance filtering machines, designed for the rigors of high-volume processing. We understand that your goal is to produce a professional product with maximum efficiency.

To find the right filtering system that aligns with your market strategy and operational needs, Contact Our Experts.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

Related Articles

- How Honey Heating Tanks Preserve Quality and Efficiency in Modern Beekeeping

- How to Optimize Steam Wax Melting for Higher Yields and Safer Operations

- Heat, Honey, and Haste: The Physics of Preserving Liquid Gold

- How Honey Processing Affects Nutrition: Science-Backed Insights for Healthier Choices

- How to Choose Between Semi-Automatic and Fully Automatic Honey Filling Machines