Steam wax melters are indispensable for beekeepers looking to efficiently harvest wax while preserving comb integrity. Yet improper operation can lead to wasted wax, equipment damage, or even safety hazards. This guide distills professional techniques to help you achieve consistent results—whether you're processing a few frames or managing large-scale extraction.

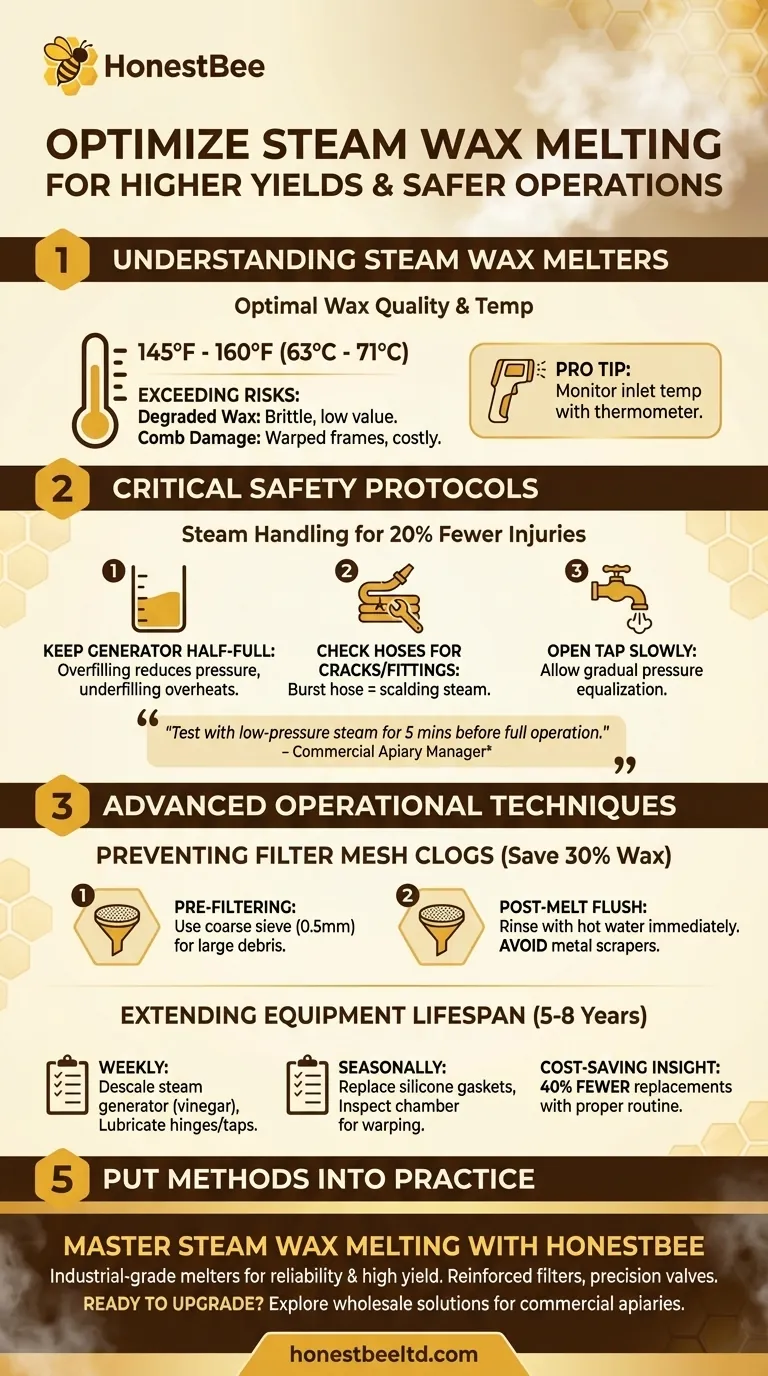

Understanding Steam Wax Melters

How Steam Temperature Affects Wax Quality

Wax melts optimally between 145°F and 160°F (63°C–71°C). Exceeding this range risks:

- Degraded wax quality: Overheated wax becomes brittle and loses market value.

- Comb damage: High temperatures warp frames, requiring costly replacements.

Pro Tip: Use a thermometer to monitor steam temperature at the melter’s inlet. If your system lacks a built-in gauge, infrared thermometers offer a quick workaround.

Critical Safety Protocols for Steam Handling

Steam-related accidents account for nearly 20% of beekeeping equipment injuries (source: Beekeeping Safety Institute). Mitigate risks with these steps:

- Water level vigilance: Keep the steam generator filled to half capacity—overfilling reduces steam pressure, while underfilling risks overheating.

- Hose inspections: Check for cracks or loose fittings before each use. A burst hose can release scalding steam.

- Pressure release: Always open the tap slowly to allow gradual pressure equalization.

"A beekeeper in Iowa once lost an entire wax batch to a ruptured hose. Now, I test my equipment with low-pressure steam for 5 minutes before full operation." — Commercial Apiary Manager

Advanced Operational Techniques

Preventing Filter Mesh Clogs

Clogged filters waste up to 30% of recoverable wax and prolong cleanup. Two prevention strategies:

- Pre-filtering: Use a coarse sieve (e.g., 0.5mm mesh) to remove large debris before melting.

- Post-melt flush: Rinse filters with hot water immediately after use—cooled wax residue hardens into stubborn blockages.

Common Mistake: Avoid using metal scrapers to clean filters; they create micro-tears that trap wax particles over time.

Extending Equipment Lifespan

Steam wax melters typically last 5–8 years with proper care. Key maintenance practices:

-

Weekly:

- Descale the steam generator with white vinegar to prevent mineral buildup.

- Lubricate hinges and taps with food-grade grease.

-

Seasonally:

- Replace silicone gaskets if they show stiffness or cracks.

- Inspect the melting chamber for warping from prolonged heat exposure.

Cost-Saving Insight: Commercial apiaries that adopt these routines report 40% fewer equipment replacements over a decade.

Put These Methods Into Practice

Mastering steam wax melting isn’t just about technique—it’s about integrating systems that protect both your product and your team. HONESTBEE’s industrial-grade melters are engineered for beekeepers who demand reliability, featuring reinforced stainless steel filters and precision pressure valves to simplify high-yield operations.

Ready to upgrade your wax harvesting? Explore our wholesale solutions designed for commercial apiaries and distributors—where efficiency meets durability.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

Related Articles

- How to Clean Beeswax Properly: A Step-by-Step Guide to Preserving Quality

- How Beekeepers Turn Wax Cappings From Waste to Profit

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- The Unseen Engine of the Hive: Decoding the Economics of Wax Production