For beekeepers, honey extraction should be a rewarding process—not a source of equipment failures and costly repairs. Imbalanced loads and weak frames are among the top causes of extractor breakdowns, but with the right techniques, these issues are entirely preventable. This guide reveals practical methods to optimize your extractor’s performance, whether you use radial, tangential, or manual systems.

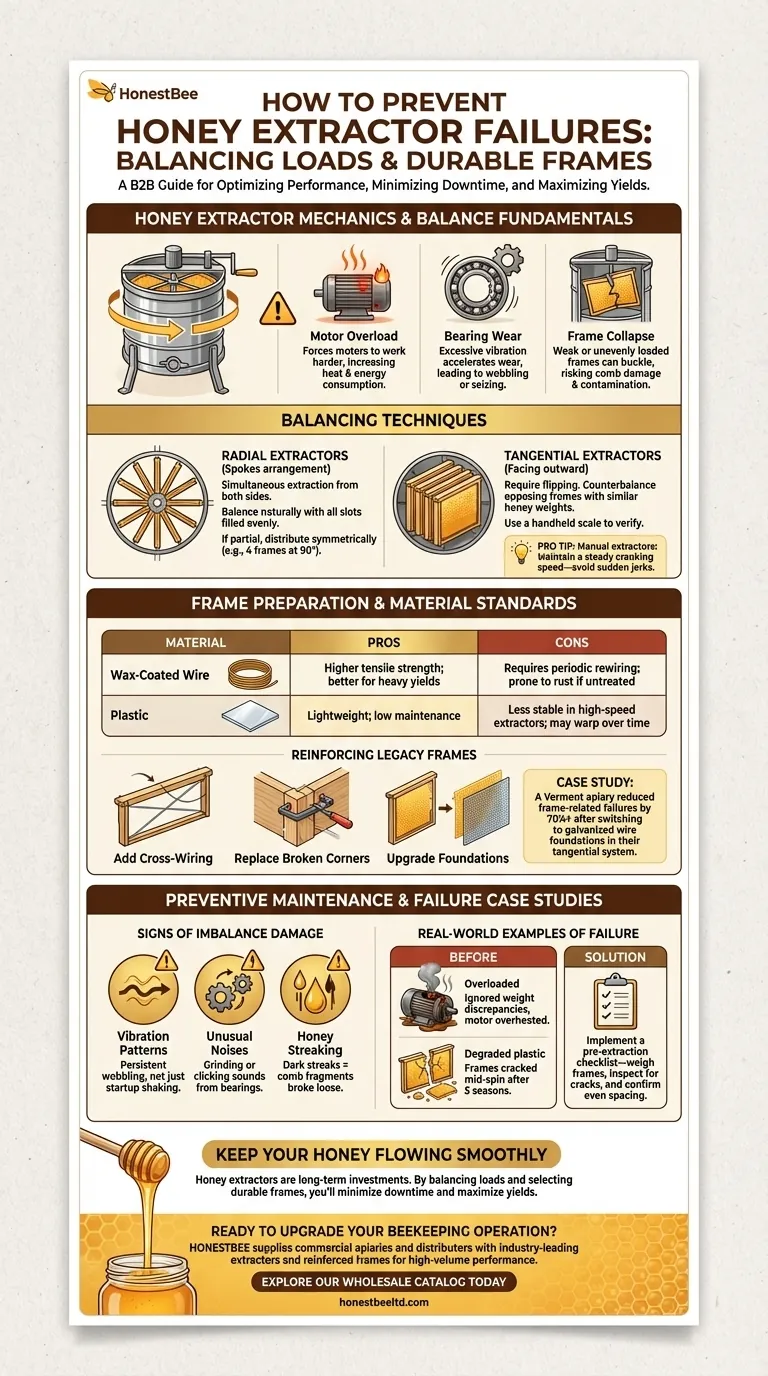

Honey Extractor Mechanics and Balance Fundamentals

Honey extractors rely on precise spinning to remove honey without damaging combs. When loads are uneven, the resulting vibrations strain motors, bearings, and structural welds, shortening the equipment’s lifespan.

How Unbalanced Loads Stress Extractor Components

- Motor Overload: Uneven weight distribution forces motors to work harder, increasing heat buildup and energy consumption.

- Bearing Wear: Excessive vibration accelerates wear on ball bearings, leading to wobbling or seizing.

- Frame Collapse: Weak or unevenly loaded frames can buckle mid-spin, risking comb damage and honey contamination.

Radial vs. Tangential Extractor Balancing Techniques

Radial Extractors (frames arranged like wheel spokes):

- Allow simultaneous extraction from both sides of frames, reducing spin time.

- Balance naturally when all frame slots are filled evenly. If partially loaded, distribute frames symmetrically (e.g., place 4 frames at 90-degree intervals instead of clustering 3 on one side).

Tangential Extractors (frames face outward):

- Require flipping frames halfway through extraction.

- Counterbalance by ensuring opposing frames have similar honey weights before spinning. Use a handheld scale to verify.

Pro Tip: For manual extractors, maintain a steady cranking speed—sudden jerks amplify imbalance forces.

Frame Preparation and Material Standards

Frames endure immense centrifugal force during extraction. Choosing durable materials and reinforcing older frames can prevent mid-process failures.

Wire vs. Plastic Foundations: Durability Comparison

| Material | Pros | Cons |

|---|---|---|

| Wax-Coated Wire | Higher tensile strength; better for heavy honey yields | Requires periodic rewiring; prone to rust if untreated |

| Plastic | Lightweight; low maintenance | Less stable in high-speed extractors; may warp over time |

Reinforcing Legacy Frames for Modern Extractors

- Add Cross-Wiring: Secure older wooden frames with stainless-steel wire through side bars.

- Replace Broken Corners: Use wood glue and clamps to repair splits before they worsen under spin forces.

- Upgrade Foundations: Swap brittle wax for reinforced plastic or wired sheets if frames consistently buckle.

Case Study: A Vermont apiary reduced frame-related extraction failures by over 70% after switching to galvanized wire foundations in their tangential system.

Preventive Maintenance and Failure Case Studies

Recognizing early warning signs of imbalance or frame fatigue can save thousands in equipment replacements.

Signs of Imbalance Damage to Monitor

- Vibration Patterns: Mild shaking is normal at startup, but persistent wobbling indicates imbalance.

- Unusual Noises: Grinding or clicking suggests bearing wear from prolonged uneven loads.

- Honey Streaking: Dark streaks in extracted honey often mean comb fragments broke loose during spin.

Real-World Examples of Extraction Failures

- Overloaded Tangential Extractor: A commercial beekeeper ignored weight discrepancies between frames, causing the motor to overheat and melt critical wiring.

- Degraded Plastic Frames: After five seasons, a radial extractor’s plastic frames cracked mid-spin, scattering comb fragments into 30 gallons of honey.

Solution: Implement a pre-extraction checklist—weigh frames, inspect for cracks, and confirm even spacing.

Keep Your Honey Flowing Smoothly

Honey extractors are long-term investments. By balancing loads strategically and selecting durable frames, you’ll minimize downtime and maximize yields.

Ready to upgrade your beekeeping operation? HONESTBEE supplies commercial apiaries and distributors with industry-leading extractors and reinforced frames designed for high-volume performance. Explore our wholesale-focused catalog today—because reliable equipment should be the least of your worries.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

Related Articles

- How Automatic Honey Extractors Cut Costs and Boost Scalability for Commercial Beekeepers

- How to Extract Honey Sustainably: Maximizing Yield Without Harming Bees

- Honey Press vs. Extractor: Why Your Choice Defines Your Apiary's Profitability

- How to Choose the Right Honey Extraction Method for Your Beekeeping Needs

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability