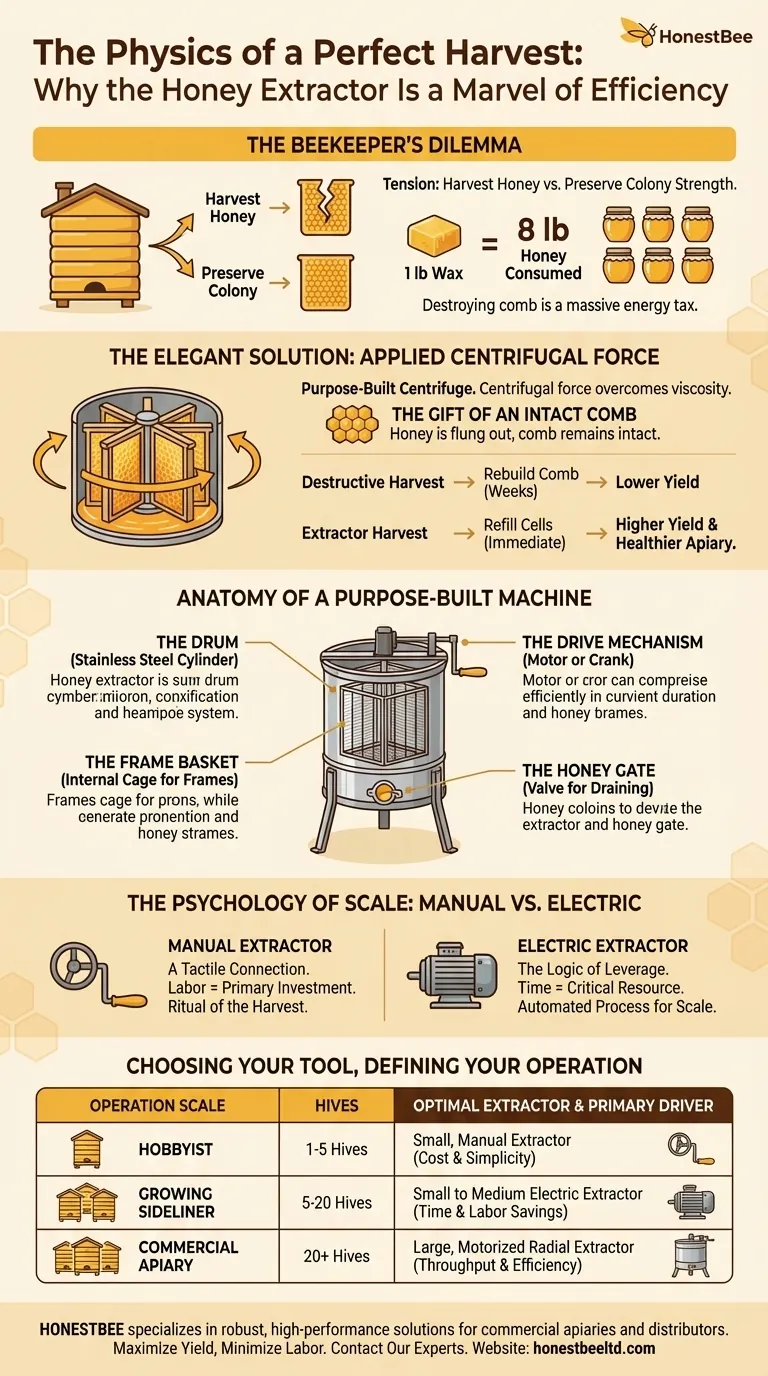

The Beekeeper's Dilemma

At the heart of beekeeping lies a fundamental tension: the desire to harvest honey versus the need to preserve the colony's strength.

Bees invest an immense amount of energy in building wax honeycomb. For every pound of wax they produce, they consume roughly eight pounds of honey. Destroying this intricate structure during a harvest forces the colony to start from scratch—a massive energy tax that reduces their overall productivity and resilience.

How do you take the honey without taking the home? For centuries, this was a destructive process. Today, the solution is an elegant piece of machinery: the honey extractor.

The Elegant Solution: Applied Centrifugal Force

A honey extractor is, at its core, a purpose-built centrifuge. It solves the beekeeper's dilemma not with brute force, but with the simple, relentless logic of physics.

When the honeycomb frames spin, every drop of honey inside feels a powerful outward pull. This centrifugal force overcomes the honey's natural viscosity and its adhesion to the wax cell walls. The honey is flung out, while the delicate comb—the bees' architectural masterpiece—remains almost entirely intact.

The Gift of an Intact Comb

This is the machine's quiet genius. By preserving the comb, we're not just saving wax; we're saving the bees' most precious resource: time and energy.

The bees can immediately begin refilling the empty cells, rather than spending weeks rebuilding their pantry. For a commercial apiary, this translates directly into higher yields and a healthier, more productive apiary. It changes the beekeeper's role from a simple harvester to a steward of a complex biological system.

Anatomy of a Purpose-Built Machine

Though models vary, every extractor operates on the same principles and shares a common anatomy designed for one specific task.

- The Drum: A large, stainless steel cylinder that contains the spinning frames and serves as the collection vessel for the extracted honey.

- The Frame Basket: The internal cage that holds the frames securely as they rotate at high speed. Its design dictates whether it's a tangential (one side at a time) or radial (both sides at once) extractor.

- The Drive Mechanism: The engine of the operation. This can be a hand crank for manual models or an electric motor for automated ones. It's what generates the spin.

- The Honey Gate: A simple valve at the bottom of the drum. Once honey pools, this gate is opened to drain the pure, liquid gold.

The Psychology of Scale: Manual vs. Electric

The choice between a manual and electric extractor isn't just about technology; it's a reflection of a beekeeper's goals, ambition, and relationship with time.

The Manual Extractor: A Tactile Connection

For the hobbyist with a few hives, a hand-crank extractor offers control and simplicity. The physical effort is part of the ritual of the harvest—a direct connection to the work. The operator feels the load lighten as the honey is expelled. The primary investment is labor, not capital. It's a tool for those who value the process as much as the product.

The Electric Extractor: The Logic of Leverage

For a growing or commercial operation, the psychology shifts. Time becomes the most critical, non-renewable resource. An electric motor automates the most labor-intensive part of the harvest, transforming the operator's role from a source of power to a manager of an efficient process.

This isn't just a convenience; it's a strategic investment in scale. It allows one person to process significantly more honey in a day, making a commercial apiary viable and profitable. The decision to upgrade to an electric model is often the first sign a beekeeper is transitioning from a passion to a business.

Choosing Your Tool, Defining Your Operation

The right extractor aligns with the scale of your ambition.

| Operation Scale | Hives | Optimal Extractor | Primary Driver |

|---|---|---|---|

| Hobbyist | 1-5 Hives | Small, Manual Extractor | Cost & Simplicity |

| Growing Sideliner | 5-20 Hives | Small to Medium Electric Extractor | Time & Labor Savings |

| Commercial Apiary | 20+ Hives | Large, Motorized Radial Extractor | Throughput & Efficiency |

For commercial apiaries and distributors, equipment is not just a tool—it's the backbone of the operation. Reliability and efficiency aren't luxuries; they are essential for profitability. At this scale, the honey extractor must be a durable workhorse, capable of handling high volumes season after season.

HONESTBEE specializes in supplying these robust, high-performance beekeeping solutions to commercial apiaries and equipment distributors. If your operation depends on maximizing yield and minimizing labor, having the right equipment is the most important decision you can make. Contact Our Experts

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

Related Articles

- How to Choose the Right Honey Extractor for Your Beekeeping Scale

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- How to Extract Honey Sustainably: Maximizing Yield Without Harming Bees

- Tangential vs Radial Honey Extractors: How to Choose for Your Beekeeping Needs

- Honey Press vs. Extractor: Why Your Choice Defines Your Apiary's Profitability