The Beekeeper's Dilemma: A Tale of Two Materials

Imagine a sweltering July afternoon. A commercial beekeeper, managing hundreds of hives, opens a box to a scene of devastation. The wax foundation, softened by the oppressive heat, has collapsed into a single, sticky mass of honey, wax, and dead brood. The entire frame is a loss, a setback in both time and production.

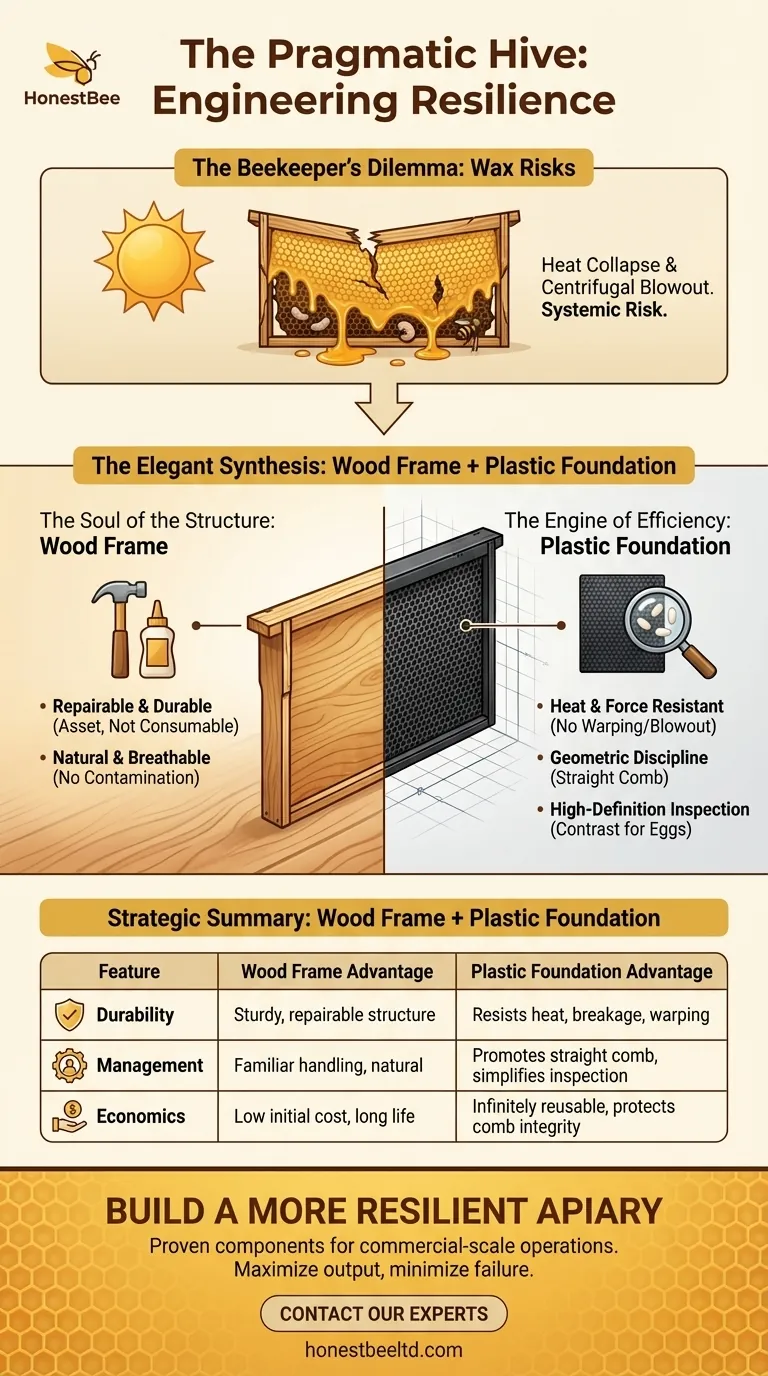

This scenario isn't hypothetical; it's a systemic risk rooted in material science. Beekeeping has always existed at the intersection of nature and human intervention. The choice of equipment reflects this tension—a constant negotiation between tradition and technology, between the organic and the engineered.

For decades, the debate has centered on frames and foundation. But the most resilient solution isn't a victory for one side. It's an elegant synthesis: the wooden frame paired with a plastic foundation.

The Soul of the Structure: The Enduring Appeal of Wood

The frame is the skeleton of the hive. Wood remains the material of choice for this structure, not just out of tradition, but for deep, practical reasons.

The Psychology of Repairability

Wooden frames are famously rigid and durable. But their true value lies in their repairability. A snapped plastic frame is trash. A broken wooden sidebar can be glued, nailed, or replaced.

This isn't just about saving money; it's a psychological comfort. It fosters a sense of ownership and sustainability. The beekeeper maintains the equipment, extending its life indefinitely. It's an asset, not a consumable.

A Tangible Connection

Wood is a natural, breathable material. For many, it feels more aligned with the spirit of beekeeping. It connects the operator to a long history of apiculture and, crucially, poses no risk of chemical contamination to the honey or wax.

The Engine of Efficiency: The Power of Plastic Foundation

If the wood frame is the soul, the plastic foundation is the hive's ruthlessly efficient engine. It solves the most common and costly points of failure found in traditional wax foundation.

Defying Physics: Heat and Centrifugal Force

Plastic is indifferent to the heat that causes wax to fail. It provides a stable, rigid backbone that will not warp or melt, securing the colony's hard work through the most intense heatwaves.

This strength extends to the harvest. During honey extraction, frames are spun at high speeds. The centrifugal force can blow out fragile wax comb, creating a time-consuming mess. Plastic foundation holds firm, preserving the meticulously drawn comb for the bees to immediately reuse. Less time rebuilding means more time making honey.

Engineering Predictability

Bees don't always build in straight lines. Cross-combing, where they build comb across multiple frames, can weld a hive's interior into an unmanageable block.

Rigid plastic foundation forces geometric discipline. It guides the bees to build straight, even combs every time. This simple act of engineering brings predictability to a complex biological system, making inspections faster, safer, and less disruptive for the colony.

High-Definition Brood Inspection

Assessing the health of a colony often starts with finding the eggs. Spotting tiny, white eggs against the pale, irregular background of natural wax is a notorious challenge, even for experienced eyes.

Black plastic foundation transforms the task. The high-contrast background makes eggs stand out in sharp relief. It turns a difficult art into a simple visual check. This clarity is data. Better data on the queen's laying pattern allows for faster, more accurate decisions about the health and future of the hive.

A Balanced System for Modern Apiaries

No single solution is perfect, but the hybrid system offers the most robust balance of trade-offs for commercial operations.

- All-Plastic Frames: Offer ultimate convenience, arriving ready-to-use. However, they lack the repairability and natural feel of wood.

- Wax Foundation: Appeals to purists but introduces significant risk from heat and extraction, demanding more careful management.

The wood-and-plastic system occupies the strategic middle ground, maximizing strength and efficiency while retaining the core benefits of traditional materials.

Strategic Summary: Wood Frame + Plastic Foundation

| Feature | Wood Frame Advantage | Plastic Foundation Advantage |

|---|---|---|

| Durability | Sturdy, repairable structure | Resists heat, breakage, and warping |

| Management | Familiar handling, natural | Promotes straight comb, simplifies inspection |

| Economics | Low initial cost, long life | Infinitely reusable, protects comb integrity |

For a commercial apiary or equipment distributor, equipment choice is an investment in operational resilience. The goal is to minimize catastrophic failures, streamline labor, and maximize output. The combination of wood frames and plastic foundation is not a compromise; it's a deliberate engineering choice designed to achieve exactly that.

At HONESTBEE, we specialize in supplying these proven, high-quality components for commercial-scale operations that value durability and efficiency above all. If you're ready to build a more resilient and productive apiary, Contact Our Experts.

Visual Guide

Related Products

- Food Grade Plastic bee Foundation for Bee Frames

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Durable Rubberized Comfort Handle Frame Grip

- Multi-Function Frame Grip with Integrated Hive Tool

- Premium Frame Grip with Ergonomic Wood Handles

Related Articles

- The Physics of Failure: Why Plastic Foundation is the Keystone of Modern Honey Extraction

- Plastic vs. Wax Foundations: A Data-Driven Guide for Beekeeping Success

- Is Your Plastic Foundation Costing You Honey? Why "Pre-Waxed" Might Not Be Enough

- Why Your Bees Reject Plastic Foundation—And How to Guarantee Acceptance

- Wooden vs. Plastic Bee Hive Frames: Balancing Sustainability and Practicality