The Beautiful Chaos of the Harvest

The moment of honey extraction is one of controlled chaos. It's the culmination of a season's work, a sticky, fragrant, and deeply rewarding process. But the liquid gold that flows from the extractor is not the finished product you see on a shelf.

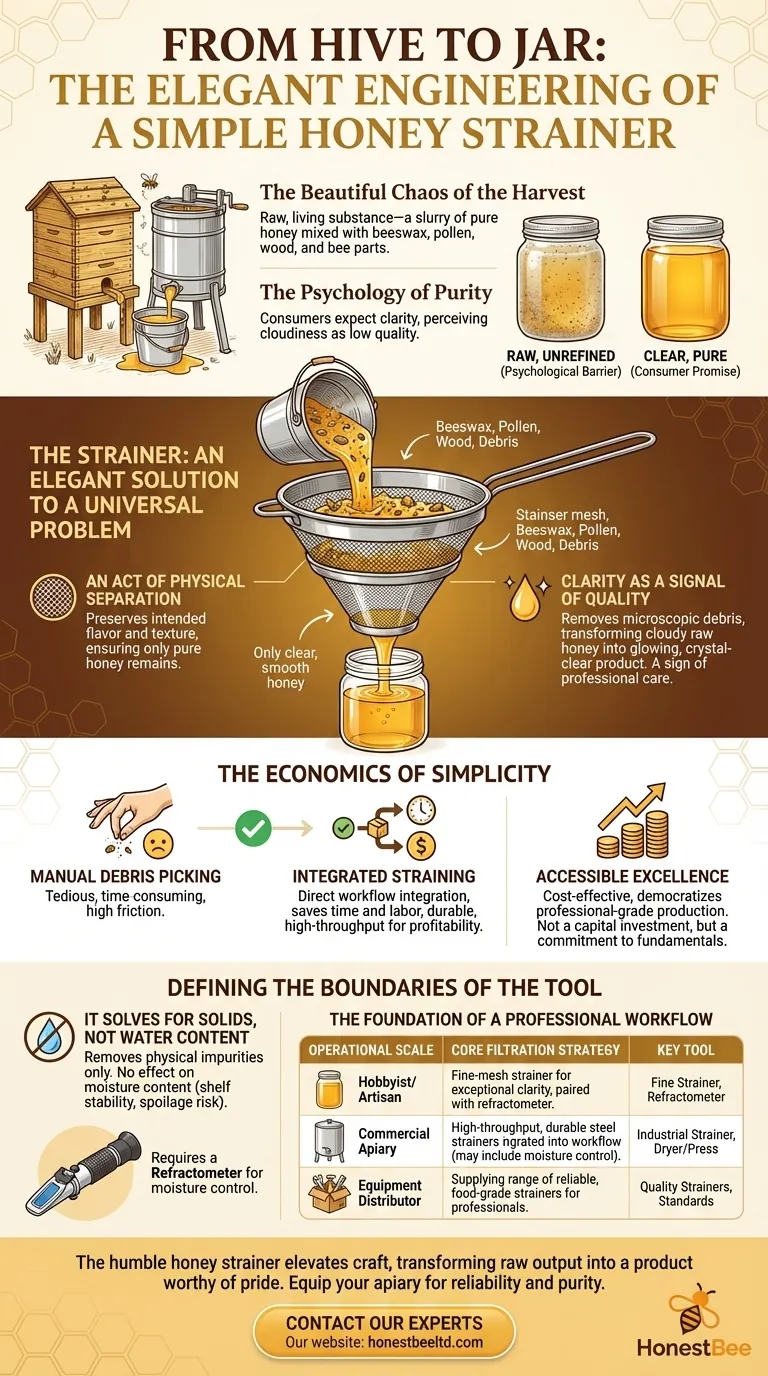

It is a raw, living substance—a slurry of pure honey mixed with the unavoidable artifacts of the hive: flecks of beeswax, pollen, wood from the frames, and even bee parts. This isn't a failure of process; it's the honest reality of working with a natural system.

The fundamental challenge, then, is not one of production, but of refinement. How do you honor the raw purity of the honey while separating it from the beautiful mess of its creation?

The Psychology of Purity

We don't buy honey expecting to find the hive inside. We buy a promise. That promise is one of purity, clarity, and quality. A consumer expects honey to be a smooth, translucent liquid. Cloudiness or visible specks, however natural, create a psychological barrier. They are perceived not as signs of an authentic harvest, but as signals of a low-quality, unrefined product.

This is the gap that every beekeeper, from the backyard hobbyist to the commercial apiary, must bridge. The solution is not complex machinery or chemical processes. It is an act of simple, elegant, mechanical separation.

The Strainer: An Elegant Solution to a Universal Problem

A honey strainer is perhaps the most under-appreciated tool in beekeeping, yet it performs the most critical transformation. It is the gatekeeper that stands between the hive and the jar.

An Act of Physical Separation

At its core, a strainer is a physical barrier. As honey flows through its fine mesh, the liquid passes while the solid impurities are left behind. This simple action is profound. It preserves the honey’s intended flavor and texture, ensuring the final product is nothing but honey, just as nature and the customer intended.

For commercial operations, this isn't just about aesthetics; it's about consistency. A reliable filtration process ensures every batch meets a predictable standard of quality.

Clarity as a Signal of Quality

The strainer’s most visible impact is clarity. By removing the microscopic debris that refracts light, it transforms cloudy, raw honey into a crystal-clear product that glows. This visual appeal is not vanity; it's a powerful, non-verbal communication of care and professionalism. It tells the customer that this product was handled with expertise.

The Economics of Simplicity

In a field filled with complex challenges, the honey strainer is a testament to the power of a simple, well-designed tool. Its value isn't just in what it does, but in how it does it.

Reducing Friction, Not Just Debris

Manually picking debris from honey is an impossibly tedious task. A strainer integrates the filtration step directly into the workflow—as you pour from the extractor to the settling tank, the job is done. This removes a massive point of friction, saving time and labor. For a commercial apiary, where efficiency is measured in dollars and hours, a durable, high-throughput strainer isn't a convenience; it's a core component of a profitable operation.

Accessible Excellence

Compared to other processing equipment, a honey strainer is incredibly cost-effective. It democratizes the ability to produce a professional-grade product. It proves that the barrier to quality is not capital investment, but a commitment to fundamentals. This is why HONESTBEE focuses on supplying robust, reliable, and perfectly engineered strainers to commercial apiaries and distributors—the tool must be as dependable as the process it serves.

Defining the Boundaries of the Tool

To master a tool, you must understand its limits. A strainer is a specialist, and its focus is singular.

It Solves for Solids, Not Water Content

A strainer's job is to remove physical impurities. It has no effect on the honey's moisture content, the unseen factor that determines its shelf stability. High moisture can lead to fermentation and spoilage.

That is the job of a different tool: the refractometer. A professional workflow pairs a high-quality strainer (for clarity) with a refractometer (for stability).

The Foundation of a Professional Workflow

Even for large-scale producers using honey dryers or screw presses, the basic principle of straining remains. It is the foundational step upon which all other processes are built. It's the first and most important act of quality control.

The right approach depends on your goals:

| Operational Scale | Core Filtration Strategy |

|---|---|

| Hobbyist/Artisan | A fine-mesh strainer for exceptional clarity, paired with a refractometer to guarantee long-term stability. |

| Commercial Apiary | High-throughput, durable steel strainers integrated into a workflow that may also include moisture control systems. |

| Equipment Distributor | Supplying a range of strainers that meet the reliability and food-grade standards required by professional beekeepers. |

Ultimately, the humble honey strainer is more than a filter. It is the instrument that elevates your craft, transforming the raw output of a beehive into a finished product worthy of pride. Ensuring every step of your process is built on a foundation of quality is the hallmark of a professional operation. To equip your apiary with tools designed for reliability and purity at a commercial scale, Contact Our Experts.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

Related Articles

- Optimizing Honey Filtration: How Mesh Sizes Shape Quality and Market Appeal

- The Confidence Barrier: Why Your First Bee Suit Is About Psychology, Not Just Protection

- Beyond the Solid Floor: A Systems Approach to Hive Ventilation and Pest Control

- How Honey Heating Tanks Preserve Quality and Efficiency in Modern Beekeeping

- The Silent Collapse: Why Strong Beehives Die Over Winter