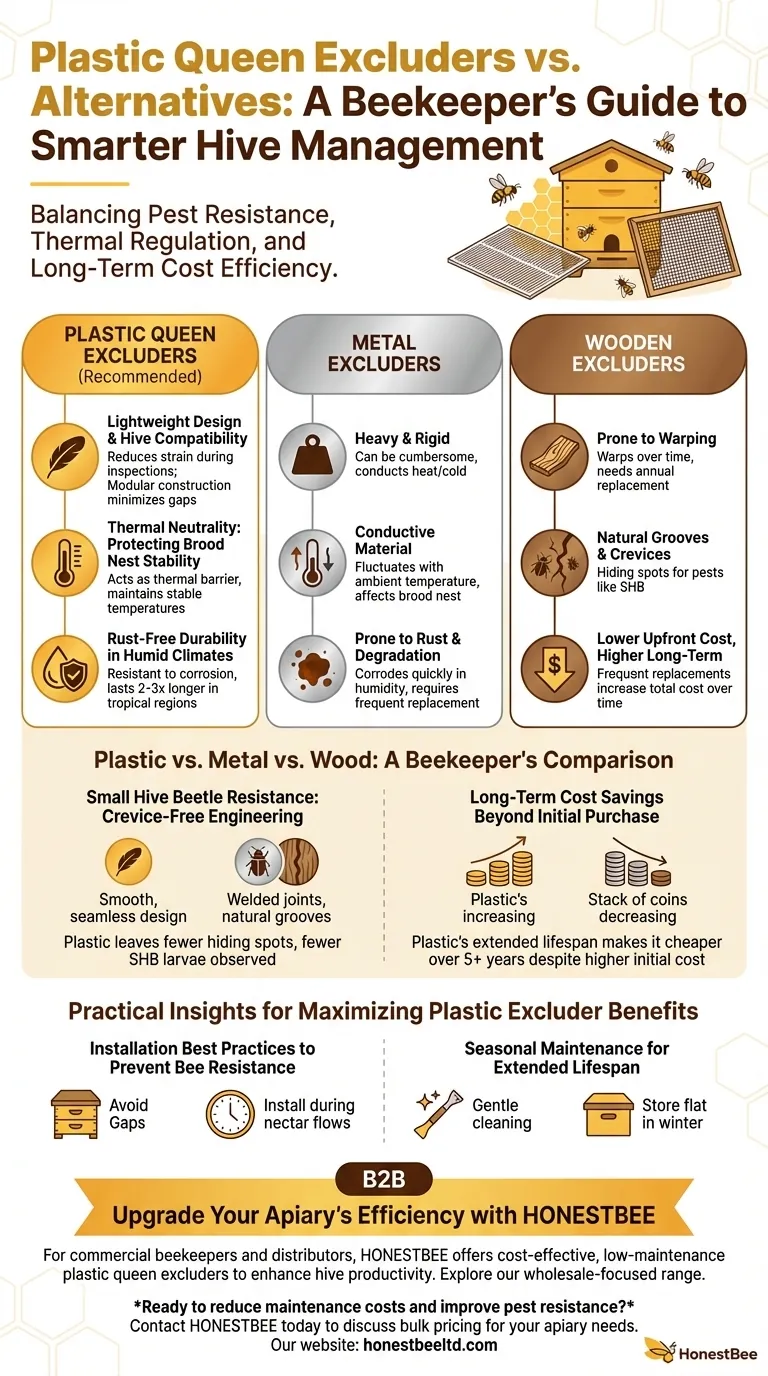

For beekeepers, choosing the right queen excluder isn’t just about separating brood from honey—it’s about balancing pest resistance, thermal regulation, and long-term cost efficiency. While metal and wood excluders have their place, modern plastic designs offer distinct advantages that address common hive challenges. Here’s how plastic excluders outperform traditional materials in real-world apiaries.

Plastic Queen Excluders: Balancing Cost and Functionality

Lightweight Design and Hive Compatibility

Plastic excluders weigh significantly less than metal or wood, reducing strain during hive inspections and rearrangements. Their modular construction ensures compatibility with most standard hive bodies, minimizing gaps that can lead to bee resistance or pest entry.

Thermal Neutrality: Protecting Brood Nest Stability

Unlike metal, which conducts heat and cold, plastic excluders act as thermal barriers. Research shows this helps maintain stable temperatures in the brood nest—a critical factor for colony health during temperature swings.

Rust-Free Durability in Humid Climates

Plastic’s resistance to corrosion makes it ideal for humid regions where metal excluders degrade faster. Beekeepers in tropical climates report plastic excluders lasting 2–3 times longer than untreated metal alternatives.

Plastic vs. Metal vs. Wood: A Beekeeper’s Comparison

Small Hive Beetle Resistance: Crevice-Free Engineering

Plastic excluders’ seamless designs leave fewer hiding spots for small hive beetles (SHB) compared to metal’s welded joints or wood’s natural grooves. Field observations note fewer SHB larvae in hives with plastic excluders, though regular maintenance remains essential.

Long-Term Cost Savings Beyond Initial Purchase

While plastic excluders may cost slightly more upfront than basic metal grids, their extended lifespan and reduced replacement needs often make them cheaper over 5+ years. Wood excluders, though affordable, typically require annual replacements due to warping.

Practical Insights for Maximizing Plastic Excluder Benefits

Installation Best Practices to Prevent Bee Resistance

- Avoid Gaps: Ensure the excluder sits flush with hive walls to prevent worker bees from bypassing it.

- Seasonal Timing: Install during nectar flows when bees are less likely to reject the barrier.

Seasonal Maintenance for Extended Lifespan

- Gentle Cleaning: Use a hive tool to scrape off propolis; avoid harsh chemicals that can degrade plastic.

- Storage: Store excluders flat in winter to prevent warping.

Upgrade Your Apiary’s Efficiency with HONESTBEE

For commercial beekeepers and distributors, HONESTBEE’s durable plastic queen excluders offer a cost-effective, low-maintenance solution to enhance hive productivity. Explore our wholesale-focused range to equip your operation with tools designed for real-world beekeeping challenges.

Ready to reduce maintenance costs and improve pest resistance? Contact HONESTBEE today to discuss bulk pricing for your apiary needs.

Products You Might Be Looking For:

Explore durable plastic queen excluders

View traditional wooden excluder options

Visual Guide

Related Products

- High Performance Plastic Queen Excluder for Beekeeping and Apiary Management

- Professional Plastic Queen Excluder for Modern Beekeeping

- Wooden Queen Bee Excluder for Beekeeping

- Plastic Queen Bee Excluder for Bee Hive Wholesale

- Premium Wood Framed Metal Wire Queen Bee Excluder

Related Articles

- How Queen Excluder Materials Shape Hive Health and Honey Yields

- How Queen Excluders Optimize Hive Productivity: Benefits, Limitations & Advanced Techniques

- Queen Excluders: Strategic Tool or Barrier to Natural Beekeeping?

- How to Choose and Optimize Queen Excluders for Healthier Hives

- How to Choose the Best Queen Excluder: Balancing Durability, Cost, and Bee Welfare