For beehive and frame manufacturers worldwide, achieving precision, efficiency, and adaptability in production is paramount. HonestBee is proud to introduce our specialized Top Bar and Bottom Bar Forming Machine, a robust and customizable solution engineered to streamline your manufacturing process, whether you're starting a new venture or upgrading your existing operations.

This machine is expertly designed to transform raw wood strips into perfectly shaped and dimensioned top bars or bottom bars for beehive frames, setting the foundation for high-quality beekeeping equipment.

Understanding the HonestBee Forming Machine: Design & Functionality

The HonestBee Top Bar and Bottom Bar Forming Machine is a testament to precision engineering, built to handle the demanding needs of bulk beehive component production.

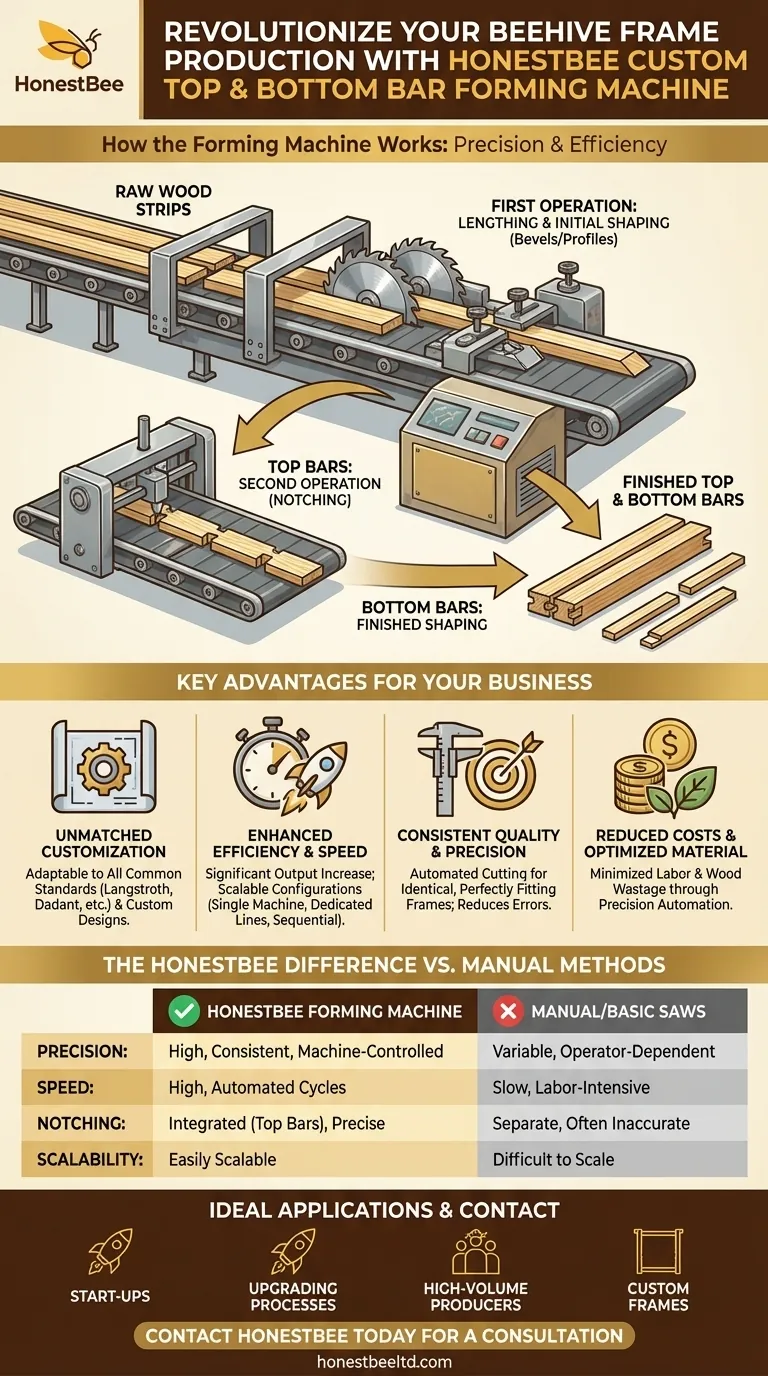

- Core Function: This machine performs the crucial initial shaping and cutting of wood strips to create either top bars or bottom bars. This includes:

- Precise Length Cutting: Ensuring every bar meets exact dimensional specifications.

- End Shaping: Creating the necessary bevels or profiles on the ends of the bars. For top bars, this involves a two-stage process to create the interlocking notches.

- Dual-Stage Operation for Top Bar:

- Initial Pass: The wood blank is fed, pneumatically clamped, and then cut to the precise length while simultaneously shaping the bevels on both ends.

- Second Pass (for Top Bars): The partially processed bar is flipped 90 degrees and re-fed. The machine then cuts the critical interlocking notches. These notches are essential for a tight, accurate fit with the frame's side bars, ensuring frame integrity.

![bee frame machine]()

![bee frame machine]()

- Adaptability for Bottom Bars: With simple adjustments, the machine can be configured to produce bottom bars, which require shaping and lengthing.

![bee frame machine]()

![bee frame machine]()

- Robust Construction: Built for durability and consistent performance in an industrial setting.

- User-Friendly Controls: Features an intuitive control panel for straightforward operation.

- Customizable Voltage: Available for 3-phase 380V or 3-phase 220V, and can be customized to meet specific local voltage requirements.

Key Advantages & Value to Your Business

Investing in the HonestBee Forming Machine brings tangible benefits to beehive frame manufacturers:

-

Unmatched Customization – Your Specifications, Our Solution:

- Adaptable to All Common Standards: Whether you produce Langstroth, British Standard, Dadant, or any other regional frame type, we can customize the machine to produce bars to your exact dimensions and profiles.

- Special Requirements Met: Have unique design needs? Our engineering team works with you to tailor the machine's cutting and shaping capabilities.

-

Enhanced Production Efficiency & Speed:

- Significant Output Increase: Far surpasses manual methods or less specialized machinery in speed and consistency.

- Multiple Configuration Options for Scalability:

- Single Machine Versatility: One machine can be adjusted to produce both top and bottom bars.

- Dedicated Lines: For higher throughput, utilize two machines – one dedicated to top bars and one to bottom bars.

- Peak Efficiency with Sequential Processing: For maximum top bar output, employ two machines in sequence. The first machine performs the initial lengthing and beveling, and the second machine performs the notching, eliminating the need to flip the wood and saving valuable time.

-

Consistent Quality & Precision:

- Automated cutting ensures every bar is identical, leading to higher quality, perfectly fitting frames.

- Reduces errors and inconsistencies common with manual processing.

-

![bee frame machine]()

-

Reduced Labor Costs & Optimized Material Usage:

- Automation reduces the manual labor required per unit.

- Precise cutting minimizes wood wastage.

-

Simplified Operations:

- While operator involvement is needed for feeding and re-orienting material (in some configurations), the cutting process itself is automated and reliable.

How the HonestBee Forming Machine Works in Your Production Line

Integrating our Forming Machine is a straightforward process:

- Material Preparation: Start with appropriately sized wood strips.

- Machine Setup: Adjust the machine for the specific bar type (top or bottom) and desired dimensions.

- First Operation (Lengthing & Initial Shaping):

- The operator places the wood blank into the machine's infeed.

- A pneumatic clamp secures the wood.

- The machine automatically feeds the wood through the first set of saws, cutting it to the precise length and shaping the ends (e.g., bevels).

- Second Operation (Notching - Primarily for Top Bars):

- The operator removes the partially processed bar.

- For top bars, the operator flips the bar 90 degrees and re-inserts it into the machine.

- The machine then cuts the interlocking notches essential for assembly with side bars.

- Output: The finished top or bottom bar is ready for the next stage (e.g., grooving, if required).

Important Note: This machine is specifically for forming the bars. For creating the inner groove (for foundation wax or plastic), a separate HonestBee Top Bar and Bottom Bar Grooving Machine is required. We can provide a complete solution for your frame component needs.

Application Scenarios: Ideal For

- New Beehive & Frame Manufacturing Start-ups: Provides a robust, customizable, and efficient foundation for your production.

- Existing Manufacturers Upgrading Their Process: Replace outdated, inefficient, or inconsistent methods with a modern, precise solution.

- High-Volume Producers: Scale your output significantly with single or multiple machine setups.

- Producers of Specialized or Custom Frames: Our customization capabilities ensure your unique design needs are met.

Operational Considerations & Safety

- Training: Ensure operators are properly trained on machine setup, operation, and safety procedures.

- Maintenance: Regular cleaning and blade maintenance are crucial for optimal performance and longevity.

- Safety Guards: The machine is designed with safety guards; always ensure they are in place and functional.

- Dust Collection: Utilize the integrated dust extraction ports to maintain a clean and safe working environment.

The HonestBee Difference vs. Other Methods

| Feature | HonestBee Forming Machine | Manual/Basic Saws |

|---|---|---|

| Precision | High, consistent, machine-controlled | Variable, operator-dependent |

| Speed | High, automated cutting cycles | Slow, labor-intensive |

| Customization | Fully customizable for any frame type/size | Limited, requires complex jigs/setups |

| Notching | Integrated (for top bars), precise | Separate, often inaccurate operation |

| Labor Cost | Reduced due to automation | High |

| Waste | Minimized due to precision | Potentially higher |

| Scalability | Easily scalable with multiple units/setups | Difficult to scale efficiently |

Elevate Your Beehive Frame Production with HonestBee

At HonestBee, we understand the intricacies of beehive component manufacturing. Our Top Bar and Bottom Bar Forming Machine is more than just equipment; it's a partnership to enhance your productivity, quality, and adaptability. Whether you're making Langstroth, Dadant, British Standard, or completely custom frames, we tailor our machines to your precise needs.

Ready to start producing higher quality frames more efficiently or upgrade your current manufacturing process?

Contact HonestBee today for a personalized consultation. Let us show you how our custom-engineered machinery can transform your beehive frame production and help your business thrive!

Visual Guide

Related Products

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Langstroth Screen Bottom Board for Beekeeping Wholesale

Related Articles

- The Art of Intervention: A Systems Approach to Beehive Maintenance

- Beyond the Pry Bar: The Physics and Psychology of the J-Hook Hive Tool

- Essential Beekeeping Equipment for Beginners: Functions, Selection, and Best Practices

- More Than Steel: The Hive Tool as a Vector for Apiary Health

- The Gentle Art of Leverage: Why Your Hive Tool Isn't a Crowbar