The First Rule of Beeswax is a Lesson in Patience

Imagine a beekeeper holding a frame heavy with cappings—a messy, sticky, beautiful byproduct of a honey harvest. This raw material is potential in solid form. It can become candles, cosmetics, or polished wood finishes.

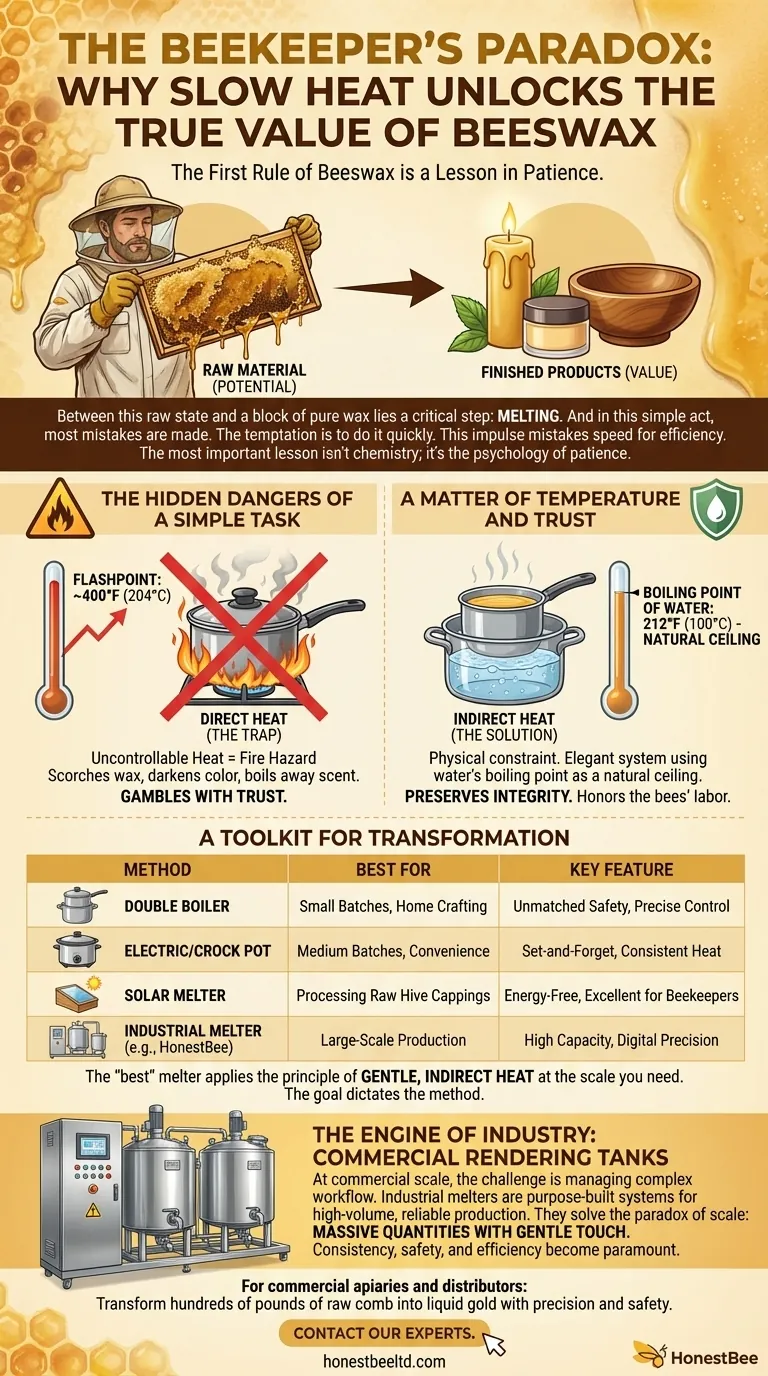

But between this raw state and a block of pure, golden wax lies a single, critical step: melting.

And in that simple act of applying heat, most mistakes are made. The temptation is to do it quickly. To put a pot on a direct flame and get the job done. This impulse, however, is a cognitive trap. It mistakes speed for efficiency and ignores the fundamental nature of the material.

The most important lesson in working with beeswax isn't about chemistry; it's about the psychology of patience.

The Hidden Dangers of a Simple Task

Beeswax is not an inert substance. It is a flammable, organic material with a "memory" of the heat it has endured. How you liquefy it determines both its safety and its final quality.

A Matter of Temperature and Trust

Every flammable material has a flashpoint—a temperature at which its vapors can ignite with a spark. For beeswax, this is around 400°F (204°C). A pot placed on a direct stove burner can easily and uncontrollably exceed this temperature.

Using indirect heat, like a double boiler, is a physical constraint. It’s an elegant system that uses the boiling point of water (212°F / 100°C) as a natural, unbreachable temperature ceiling. You are not just melting wax; you are building a system of trust that prevents disaster. Rushing the process gambles with that trust.

Preserving the Bees' Signature

Even below the flashpoint, excessive heat inflicts a different kind of damage. It scorches the wax, darkening its brilliant yellow color and boiling away the subtle, irreplaceable scent of honey.

Gentle heat doesn't just melt the wax; it preserves its integrity. It honors the immense biological labor required to produce it. Scorched wax is a sign that the processor’s haste has overwritten the signature of the hive.

A Toolkit for Transformation

The "best" wax melter is simply the tool that applies this principle of gentle, indirect heat at the scale you need. The goal dictates the method.

The Alchemist’s Setup: The Double Boiler

For the hobbyist making a few candles, this is the gold standard. A small pot of wax inside a larger pot of water. It is a perfect, small-scale application of thermodynamics—safe, precise, and requiring almost no specialized equipment. It is control in its purest form.

The Patient Processor: Electric & Solar Melters

For those who need more volume with less supervision, electric melters (or a simple crock pot on low) provide hours of steady, low heat. It’s a hands-off solution for the busy artisan.

The solar melter is an even more elegant expression of patience. It uses the sun’s energy inside an insulated box to slowly render wax from raw comb. It is slow, silent, and costs nothing to run—a favorite tool for beekeepers cleaning cappings right at the apiary.

The Engine of Industry: Commercial Rendering Tanks

What happens when your "small batch" is 500 pounds?

At commercial scale, the challenge is no longer just melting wax but managing a complex workflow. Consistency, safety, and efficiency become paramount. This is where improvised solutions fail and engineered systems become necessary.

Industrial melters from suppliers like HONESTBEE are not just bigger pots. They are purpose-built systems with digital temperature controls, insulated tanks, and safety features designed for high-volume, reliable production. They solve the paradox of scale: how to process massive quantities of wax while retaining the same gentle touch you’d use on a single block.

How to Choose Your System

Your choice of a melter is a reflection of your operational scale and your respect for the material.

| Method | Best For | Key Feature |

|---|---|---|

| Double Boiler | Small Batches, Home Crafting | Unmatched Safety, Precise Control |

| Electric/Crock Pot | Medium Batches, Convenience | Set-and-Forget, Consistent Heat |

| Solar Melter | Processing Raw Hive Cappings | Energy-Free, Excellent for Beekeepers |

| Industrial Melter | Large-Scale Production | High Capacity, Digital Precision |

Ultimately, working with beeswax teaches a profound lesson: the most effective path is rarely the fastest one. It’s the one that works with the nature of the material, not against it.

For commercial apiaries and distributors whose operations have outgrown the kitchen and backyard, applying this principle at scale requires professional-grade equipment. If you need to transform hundreds of pounds of raw comb into liquid gold with precision and safety, Contact Our Experts.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

Related Articles

- How Beekeepers Turn Old Beeswax into Profitable Ventures

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- How to Transform Old Beeswax into Profitable and Sustainable Products

- How to Melt Beeswax Safely: Temperature-Controlled Methods for Any Setting

- How to Melt Beeswax Safely: Expert Methods to Avoid Fire Risks