The Rhythm of the Harvest

Imagine the scene in a commercial honey house during peak season. Stacks of supers wait, heavy with honey. The extractor hums, ready. Every process has a bottleneck, a single point that dictates the pace of the entire operation. In honey extraction, that bottleneck is often a single blade.

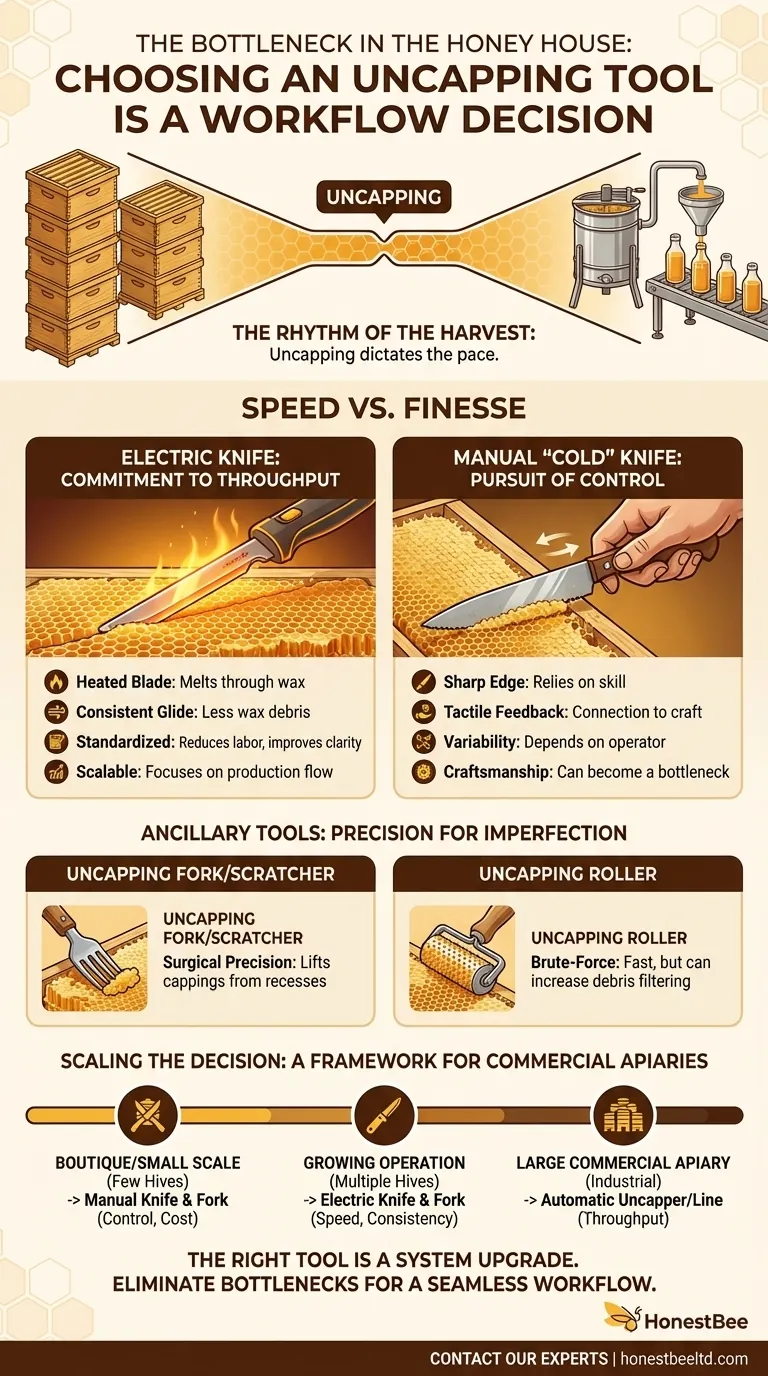

The process of uncapping—removing the thin beeswax seals from the honeycomb—is the critical gateway. The tool you choose for this task does more than just open the cells. It defines the rhythm of your harvest, influences the purity of your final product, and reflects your entire operational philosophy.

The choice isn't merely between hot steel and cold steel; it's between two mindsets: the pursuit of artisanal control versus the demand for systematic throughput.

The Anatomy of a Choice: Speed vs. Finesse

Every uncapping tool accomplishes the same goal, but the journey it takes you on is profoundly different. This distinction is where operational efficiency is won or lost.

The Electric Knife: A Commitment to Throughput

The electric uncapping knife, with its heated blade, is an instrument of pure efficiency. It doesn't cut the wax; it melts through it with a smooth, consistent glide.

This is more than a marginal time-saver. A clean, hot cut means less wax debris falls into the honey. This simplifies the filtering process downstream, reducing labor and improving the clarity of the final product. It transforms uncapping from a physically demanding art into a standardized, repeatable task.

For an operator processing hundreds of frames, this tool minimizes physical strain and cognitive load. The focus shifts from the technique of the cut to the steady flow of the production line. It’s a commitment to scale.

The Manual "Cold" Knife: The Pursuit of Control

The manual, or "cold," knife is the classicist's choice. It relies on a sharp edge and the beekeeper's skill, using a gentle sawing motion to shave off the cappings. There is no power cord, no waiting for it to heat up—just steel and intention.

This tool offers complete tactile feedback and control. You feel the blade's interaction with the comb. For a beekeeper with a few hives, this connection is part of the craft.

However, mastery takes time, and at a commercial scale, it introduces variability. The speed and quality of the work depend entirely on the operator's skill and endurance. It's a tool that rewards craftsmanship but can become a significant bottleneck under pressure.

The Ancillary Tools: Precision for Imperfection

No honeycomb frame is perfect. Knives, both electric and manual, can miss the low spots and uneven patches. This is where supplementary tools become essential.

- The Uncapping Fork/Scratcher: This tool is for surgical precision. Its sharp tines lift cappings from recessed areas a blade cannot reach. In any serious operation, a fork isn't an alternative to a knife; it's a necessary partner.

- The Uncapping Roller: A roller perforates the cappings with small spikes. It's fast, but it's a brute-force method. It can push more wax fragments down into the cells, complicating the filtering stage—a trade-off most quality-focused commercial operations are unwilling to make.

Scaling the Decision: A Framework for Commercial Apiaries

The right tool depends entirely on the scale of your ambition. A hobbyist thinks about the cost of a single tool; a commercial apiary manager must think about the cost of a bottleneck.

The tipping point from manual to electric isn't just about the number of hives. It's about when the value of your time and the efficiency of your workflow outweigh the initial investment in equipment.

| Operational Profile | Primary Tool | Core Rationale |

|---|---|---|

| Boutique/Small Scale | Manual Knife & Fork | Maximizes control and minimizes cost; workflow is secondary. |

| Growing Operation | Electric Knife & Fork | Prioritizes speed and consistency to break production bottlenecks. |

| Large Commercial Apiary | Automatic Uncapper/Line | Industrial-scale throughput; manual tools for cleanup only. |

For a growing apiary, investing in the right equipment is not an expense; it's an expansion of capacity. The efficiency gained at the uncapping table cascades through your entire operation, from extraction to bottling.

The Right Tool is a System Upgrade

In the end, the uncapping tool is the gatekeeper of the honey house. Choosing the right one is less about the tool itself and more about designing a smarter, more fluid system for your harvest. The elegance of a well-run apiary lies in this harmony, where no single step hinders the next.

At HONESTBEE, we understand this dynamic. We provide commercial apiaries and distributors with the high-quality, durable equipment needed to build efficient, scalable honey processing systems. We focus on wholesale so you can focus on building a seamless workflow, from the first uncapped frame to the last filled jar.

If you're ready to eliminate the bottlenecks in your honey house, Contact Our Experts.

Visual Guide

Related Products

- Professional Extra-Wide Uncapping Fork with Bent Tines for Beekeeping

- Professional Wide Head Honey Uncapping Fork for Beekeeping

- Professional Z-Shaped Multi-Function Uncapping Knife for Beekeeping

- Extra-Wide All-Stainless Steel Honey Uncapping Fork with T-Handle

- Professional Durable Plastic Handle Honey Uncapping Fork

Related Articles

- Why Uncapped Honeycombs Demand Caution: Science-Based Beekeeping Practices

- The Extractor's Bottleneck: Why Your Uncapping Tank Defines Your Harvest

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability

- How Beekeepers Can Maximize Honey Yield and Beeswax Quality from Cappings

- How to Clean Your Honey Extractor Safely Without Compromising Honey Quality