To recycle combs from culled frames, a double vat system uses a large, heated water bath to melt the old comb directly off the wooden frames. This process allows the raw beeswax to float to the surface for collection while the now-bare frames can be simultaneously scraped clean and decontaminated in the hot water.

The double vat method is a highly efficient beekeeping practice that combines three critical tasks into one process: rendering valuable beeswax, cleaning wooden frames for reuse, and sanitizing equipment to promote colony health.

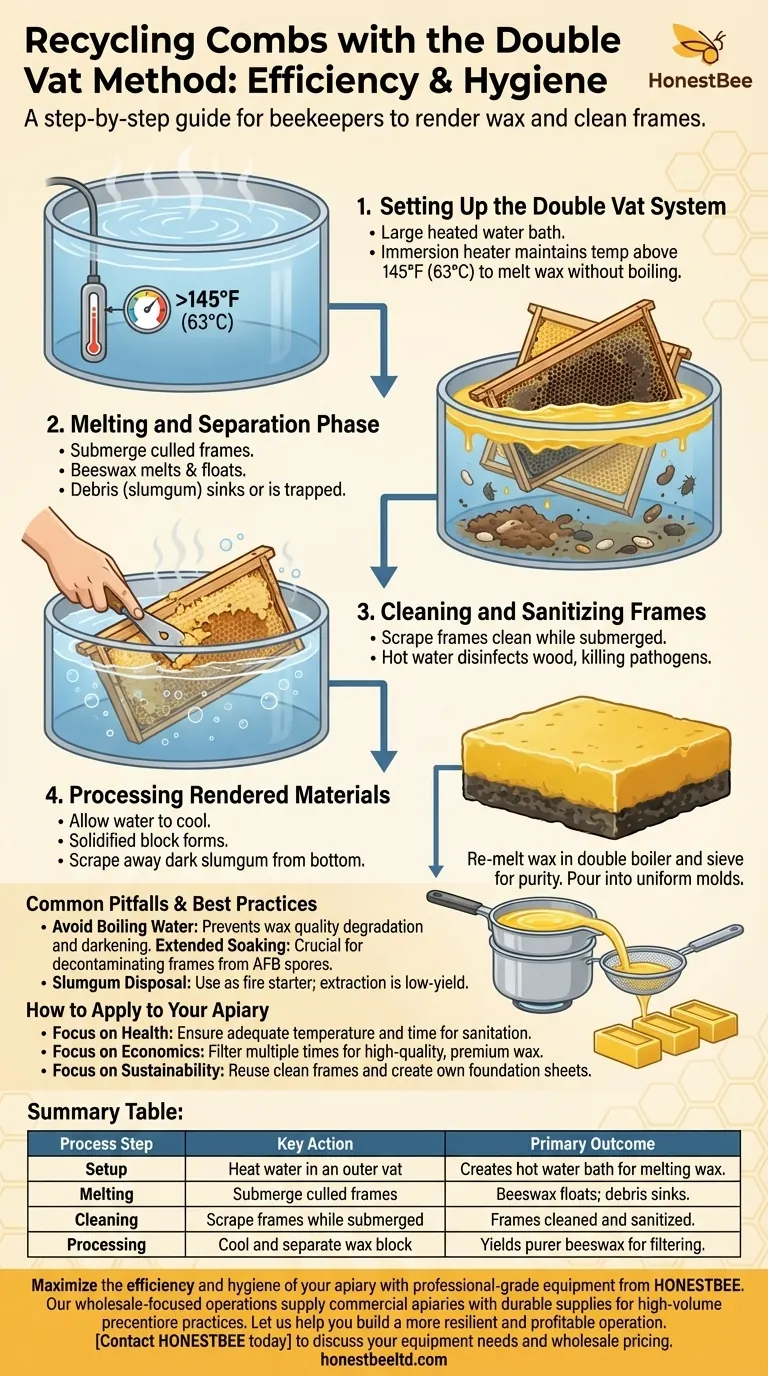

The Double Vat Process: A Step-by-Step Breakdown

The core of this system is using hot water as the medium to separate the wax from the frame. This is a common and effective method for processing a large number of frames at once.

H3: Setting Up the Vat System

Your setup will consist of a large outer vat, which can be a repurposed drum or a specialized tank, filled with water. An immersion heater is placed in the water to bring it to a temperature high enough to melt beeswax (above 145°F or 63°C) but without boiling it.

H3: The Melting and Separation Phase

The old, culled frames are submerged directly into the hot water bath. As the heat penetrates the comb, the beeswax melts and, being less dense than water, floats to the surface. Heavier debris, such as cocoons and propolis (known as slumgum), will either sink or become trapped in the floating wax layer.

H3: Cleaning the Wooden Frames

While submerged in the hot bath, the wooden frames become much easier to clean. Once the wax has melted away, you can use a hive tool to scrape off any remaining propolis or residue. The hot water effectively sterilizes the wood, making this a one-step cleaning and decontamination process.

Processing Your Rendered Materials

Once the frames are clean, your attention shifts to the valuable wax and the byproduct, slumgum. The job is not finished until the wax is filtered and ready for use.

H3: Forming the Wax/Slumgum Block

After you have processed all your frames, turn off the heater and allow the water to cool completely. As it cools, the floating layer of melted wax and slumgum will solidify into a single, large cake or block on the surface of the water.

H3: Separating Wax from Debris

Remove the solidified block from the vat. The bottom of this block will be a dark, dense layer of slumgum, while the top will be the purer beeswax. You can easily scrape the slumgum away from the valuable wax.

H3: Sieving and Final Processing

The separated wax is then re-melted in a separate pot (a double boiler is ideal to prevent scorching). This molten wax is poured through a sieve or cheesecloth to filter out any remaining fine impurities. The clean, filtered wax can then be poured into molds or pans to create uniform blocks.

Common Pitfalls and Best Practices

This method is straightforward, but attention to detail ensures a better outcome for both your equipment and your rendered wax.

H3: Avoid Boiling the Water

Using an immersion heater gives you control, but you must avoid boiling the water. Boiling can incorporate water into the wax, making it difficult to process, and excessively high temperatures can darken your beeswax, reducing its quality.

H3: The Value of Decontamination

Soaking the frames in the hot water for an extended period does more than just clean them; it can help kill pathogens like American Foulbrood (AFB) spores. This sanitation step is a crucial part of integrated pest and disease management for your apiary.

H3: What to Do with Slumgum

Slumgum is the primary waste product of this process. While it contains a small amount of residual wax, extraction is often not worth the effort for a small-scale beekeeper. Many beekeepers use dried slumgum as an excellent fire starter.

How to Apply This to Your Apiary

The clean frames and rendered wax are valuable assets for any beekeeping operation. Your goals will determine how you use them.

- If your primary focus is hive health and sanitation: Ensure the water is hot enough and frames are soaked for an adequate period to kill potential pathogens before they are reintroduced to a colony.

- If your primary focus is economic return: Process the rendered wax carefully through multiple filtering stages to produce high-quality, clean blocks that can be sold for a premium or used to make high-value products like candles.

- If your primary focus is sustainability and self-sufficiency: Use the cleaned frames with new foundation in your hives and use the rendered wax to create your own foundation sheets, reducing your reliance on outside suppliers.

By efficiently recycling your old combs, you close the loop on your resources, improve hive hygiene, and recover a valuable product from your hard-working bees.

Summary Table:

| Process Step | Key Action | Primary Outcome |

|---|---|---|

| Setup | Heat water in an outer vat with an immersion heater. | Creates a hot water bath for melting wax. |

| Melting | Submerge culled frames directly into the hot water. | Beeswax melts and floats; debris (slumgum) sinks. |

| Cleaning | Scrape frames while submerged in hot water. | Frames are cleaned and sanitized for reuse. |

| Processing | Let wax/slumgum block form after cooling, then separate. | Yields a block of purer beeswax for further filtering. |

Maximize the efficiency and hygiene of your apiary with professional-grade equipment from HONESTBEE. Our wholesale-focused operations supply commercial apiaries and distributors with durable beekeeping supplies designed for high-volume, sustainable practices like the double vat method. Let us help you build a more resilient and profitable operation.

Contact HONESTBEE today to discuss your equipment needs and wholesale pricing.

Visual Guide

Related Products

- Electric Commercial Beeswax Melter for Factory Use

- Solar Beeswax Melter Easy Solar Wax Melter for Beeswax

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Professional Thermostatic Conical Honey Melter

People Also Ask

- Why is continuous stirring with a rod necessary during the beeswax melting stage? Maximize Your Wax Yield and Quality

- How can clean, filtered beeswax be remelted and molded? Master the Safe Double Boiler Method

- What is the process for waterproofing the hive-top feeder with beeswax? Ensure a Leak-Free Feeding System for Bees

- What is the function of professional beeswax purification and refining equipment? Boost Trade Value & Purity

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide