To reduce the loss of hive tools, the most effective strategies are to paint them a bright, unnatural color like blue to make them highly visible and to establish a consistent place to keep them during inspections, such as in a dedicated bucket. This combination of high visibility and disciplined workflow addresses the most common ways tools get misplaced.

The core issue isn't just misplacing a tool; it's the lack of a reliable system during hive inspections. The solution is to make your tool impossible to ignore and to build a simple, repeatable habit for where it belongs when not in your hand.

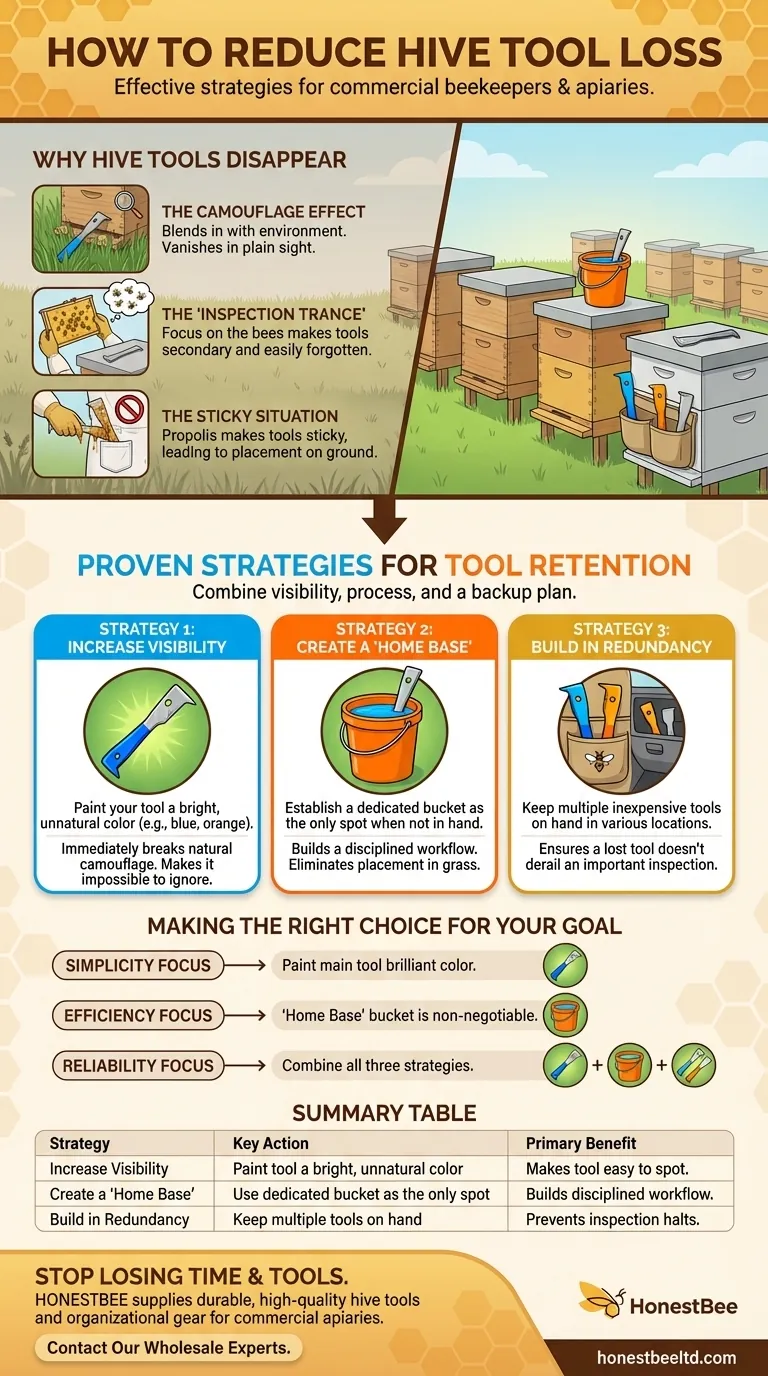

Why Hive Tools Disappear

Understanding why a hive tool gets lost is the first step toward preventing it. The problem is rarely simple carelessness but a combination of factors unique to beekeeping.

The Camouflage Effect

A standard, metallic hive tool easily blends in with grass, dirt, and hive components. When you set it down for a moment to lift a heavy super, it can vanish in plain sight.

The "Inspection Trance"

When you're focused on finding the queen, checking for mites, or assessing brood patterns, your full attention is on the frames. The hive tool becomes secondary, and it's easy to forget where you placed it last.

The Sticky Situation

Propolis makes hive tools sticky, making you reluctant to put them in a pocket. This often leads to setting the tool down on a hive roof or on the ground, where it is quickly forgotten.

Proven Strategies for Tool Retention

A truly effective solution combines visibility, process, and a backup plan. Adopting these habits will make a lost tool a rare event.

Strategy 1: Increase Visibility

The simplest and most effective tactic is to make your tool stand out.

Paint the handle or the entire tool a bright, vibrant color that doesn't naturally occur in your apiary. Blues, bright oranges, or fluorescent yellows work well. This immediately breaks the tool's natural camouflage.

Strategy 2: Create a "Home Base"

A tool can't get lost if it only ever exists in two places: your hand or its designated spot.

Keep a bucket in your apiary, perhaps with a strong washing soda solution for cleaning propolis. Make it a rigid rule: the tool is either in use or it's in the bucket. This simple discipline eliminates the risk of leaving it in the grass.

Strategy 3: Build in Redundancy

Even with the best system, mistakes happen. Experienced beekeepers know that the best backup plan is having a backup tool.

Hive tools are inexpensive. Keeping several on hand—in your bee bag, in your vehicle, and at the apiary—ensures that a lost tool doesn't derail an important inspection.

Common Pitfalls to Avoid

While these strategies are effective, it's important to be aware of their limitations to implement them correctly.

The Paint Problem

Simply spraying a tool with any paint isn't a perfect solution. The paint will inevitably chip and wear away from scraping propolis and prying frames. You must be prepared to reapply it periodically to maintain its high visibility.

The Redundancy Trap

Relying solely on having multiple tools without improving your system is a flawed approach. It treats the symptom (a missing tool) instead of the cause (a workflow that allows it to get lost). You may simply end up losing more tools over time.

Making the Right Choice for Your Goal

The best system is one you will follow consistently. Tailor your approach to your specific beekeeping style.

- If your primary focus is simplicity: Paint your main hive tool a brilliant color. This single change dramatically reduces the chances of losing it in the grass.

- If your primary focus is efficiency across multiple yards: The "home base" bucket system is non-negotiable. It creates a consistent workflow and ensures a clean tool is always ready.

- If your primary focus is absolute reliability: Combine all three strategies. Own multiple, brightly-painted tools and use a designated "home base" at all times.

By turning tool management into a deliberate habit, you can ensure your focus remains entirely on the health of your bees.

Summary Table:

| Strategy | Key Action | Primary Benefit |

|---|---|---|

| Increase Visibility | Paint tool a bright, unnatural color (e.g., blue, orange) | Makes tool easy to spot if set down in grass or on equipment |

| Create a 'Home Base' | Use a dedicated bucket as the tool's only spot when not in hand | Builds a disciplined workflow to prevent misplacement |

| Build in Redundancy | Keep multiple inexpensive tools on hand | Ensures a lost tool doesn't halt an important inspection |

Stop losing time and tools during hive inspections. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, high-quality hive tools and organizational gear needed to implement these effective strategies. Let us help you build a more efficient and reliable beekeeping operation. Contact our wholesale experts today to discuss your equipment needs!

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Durable Plastic Hive Number Set for Beekeeping

- Professional Wide Blade Honey Scraper for Beekeeping and Honey Processing

People Also Ask

- How should beekeepers handle bees when using a hive tool? Master Calm, Deliberate Techniques

- How does the hive splitting process contribute to colony management? Master Your Apiary Recovery Strategies

- What is the hole in a hive tool for? A Multi-Tool for Apiary Repairs and Maintenance

- What is the function of a professional stainless steel hive tool in IFB? Optimize Your Colony Strength Assessment

- What are the specific applications of a beekeeping chisel? Master Hive Maintenance with Precision Tools