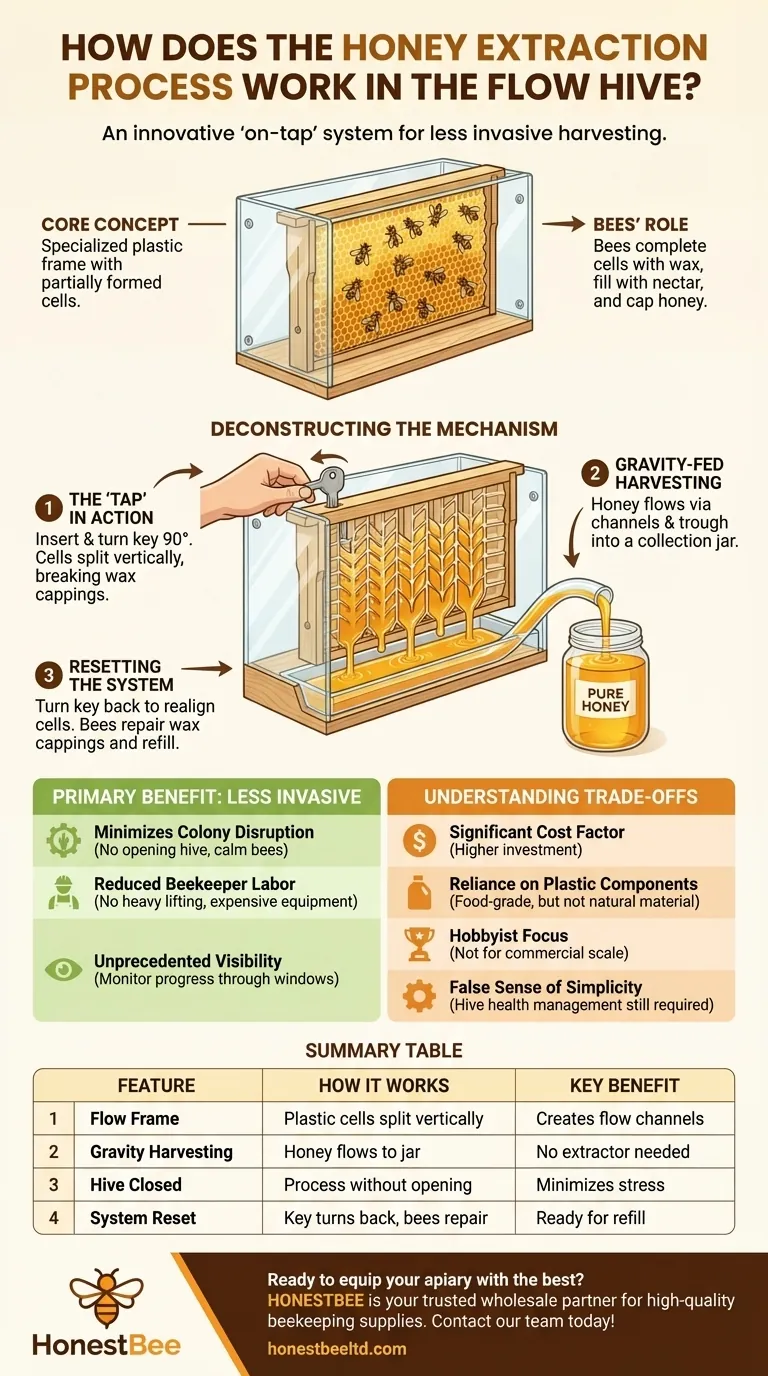

At its core, the Flow Hive extracts honey by using a specialized frame with partially formed plastic honeycomb cells. When you turn a key, the cells split vertically, breaking the bees' wax cappings and creating channels. This allows pure, filtered honey to flow directly out of the hive and into a jar via gravity, all without opening the hive or disturbing the bees.

The Flow Hive revolutionizes honey harvesting by replacing the labor-intensive, disruptive traditional extraction process with a simple "on-tap" system. However, this convenience comes with significant trade-offs in cost and a reliance on plastic components within the hive.

Deconstructing the Flow Hive Mechanism

To understand how the system works, you must first understand the unique design of its frames. The innovation isn't the beehive box itself, but what goes inside it.

The Anatomy of a Flow Frame

The system's magic lies in its food-grade, BPA and BPS-free plastic frames. These frames contain a matrix of partially formed honeycomb cells.

Crucially, these cells are not solid; they are designed to split vertically down the middle when activated.

The Role of the Bees

Bees treat the Flow Frames much like any other. They complete the partially formed cells with their own wax, fill them with nectar, and cap the honey with wax once it has been sufficiently dehydrated.

From the bees' perspective, it is a standard honeycomb structure ready for honey storage.

The "Tap" in Action

Once the beekeeper confirms the frames are full and capped (often via a clear viewing window), the harvesting process begins.

A special tool, the Flow Key, is inserted into the top of the frame and turned 90 degrees. This action shifts the two halves of the honeycomb cells, offsetting them.

This offset motion breaks the wax seals on the face of the comb, creating a continuous channel for honey to flow downwards.

Gravity-Fed Harvesting

As the cells are split, the honey flows through these newly formed channels to a sealed trough at the bottom of the frame.

From this trough, the honey exits the hive through a tube and flows directly into your collection jar. The process is entirely powered by gravity.

Resetting the System

After harvesting is complete, you simply turn the key back to its original position. This realigns the honeycomb cells.

The bees will then begin the work of repairing the broken wax cappings and will eventually refill the cells with honey, starting the process anew.

The Primary Benefit: A Less Invasive Process

The Flow Hive's design fundamentally changes the beekeeper's interaction with the colony during harvest, aiming to reduce stress on both the bees and the keeper.

Minimizing Colony Disruption

Traditional extraction requires opening the hive, removing heavy frames, brushing off bees, and transporting frames to a separate location. The Flow Hive bypasses all of this.

Because the hive remains sealed, the bees are not agitated by smoke or the sudden intrusion of a beekeeper, leading to a much calmer colony.

Reduced Beekeeper Labor

This system eliminates the need for expensive and messy extraction equipment like centrifuges, uncapping knives, and filters. It also removes the need for heavy lifting of honey-laden boxes.

Unprecedented Visibility

Most Flow Hives include clear end-frames and side observation windows. This allows the beekeeper to monitor the colony's progress and judge when the honey is ready to harvest without having to open the hive and disturb the bees.

Understanding the Trade-offs

While the convenience is clear, the Flow Hive represents a specific choice with notable compromises. It is not a universally superior system, but rather a specialized tool.

The Cost Factor

The most significant barrier is cost. A Flow Hive is a substantially larger upfront investment compared to a traditional Langstroth hive and basic beekeeping gear.

Reliance on Plastic Components

The honey-storing super frames are made of plastic. While they are food-grade and BPA/BPS-free, many beekeepers prefer to keep the hive environment as natural as possible with only wood and beeswax.

The Hobbyist Focus

The Flow Hive is designed almost exclusively for the hobbyist and backyard beekeeper. Its cost and design are not suited for commercial-scale honey production.

A False Sense of Simplicity

The simple harvesting process can mislead beginners into thinking all beekeeping is that easy. The complex work of hive inspections, pest and disease management, and ensuring colony health remains just as demanding as with any other hive.

Making the Right Choice for Your Beekeeping Goal

Choosing a hive system depends entirely on your personal goals, budget, and beekeeping philosophy.

- If your primary focus is convenience and minimal disruption: The Flow Hive's innovative tap system is an unparalleled solution that makes harvesting clean, simple, and gentle on the bees.

- If your primary focus is cost-effectiveness and traditional practice: A standard Langstroth hive with separate extraction equipment is a more economical and time-tested choice used by the majority of beekeepers worldwide.

- If your primary focus is minimizing plastic in the hive: You will want to stick with traditional wooden frames and natural beeswax foundation to maintain an all-natural hive environment.

Ultimately, understanding the mechanical ingenuity of the Flow Hive allows you to weigh its profound convenience against the costs and philosophical trade-offs of this modern approach to beekeeping.

Summary Table:

| Feature | How It Works | Key Benefit |

|---|---|---|

| Flow Frame | Plastic cells split vertically when a key is turned. | Creates channels for honey to flow out. |

| Gravity Harvesting | Honey flows downward through channels into a jar. | No need for centrifugal extractors or heavy lifting. |

| Hive Closed | The entire process happens without opening the hive. | Minimizes stress and disruption to the bee colony. |

| System Reset | Key is turned back; bees repair the wax cappings. | Frames are ready to be refilled by the bees. |

Ready to equip your apiary with the best?

Whether you manage a large commercial operation or supply equipment to other beekeepers, HONESTBEE is your trusted wholesale partner. We provide durable, high-quality beekeeping supplies and equipment designed for productivity and colony health.

Let us help you streamline your operations and maximize your yield.

Contact our wholesale team today to discuss your specific needs and explore our product catalog.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- What is the significance of professional hive-making tools? Scale Your Stingless Bee Farm with Precision Equipment

- What are the basic tools for beekeeping? Essential Starter Kit for Safe & Successful Hive Management

- What are the specific applications of a beekeeping chisel? Master Hive Maintenance with Precision Tools

- What are the primary functions of a stainless steel hive tool? Essential Equipment for Professional Beekeeping

- What is the function of a professional stainless steel hive tool in IFB? Optimize Your Colony Strength Assessment