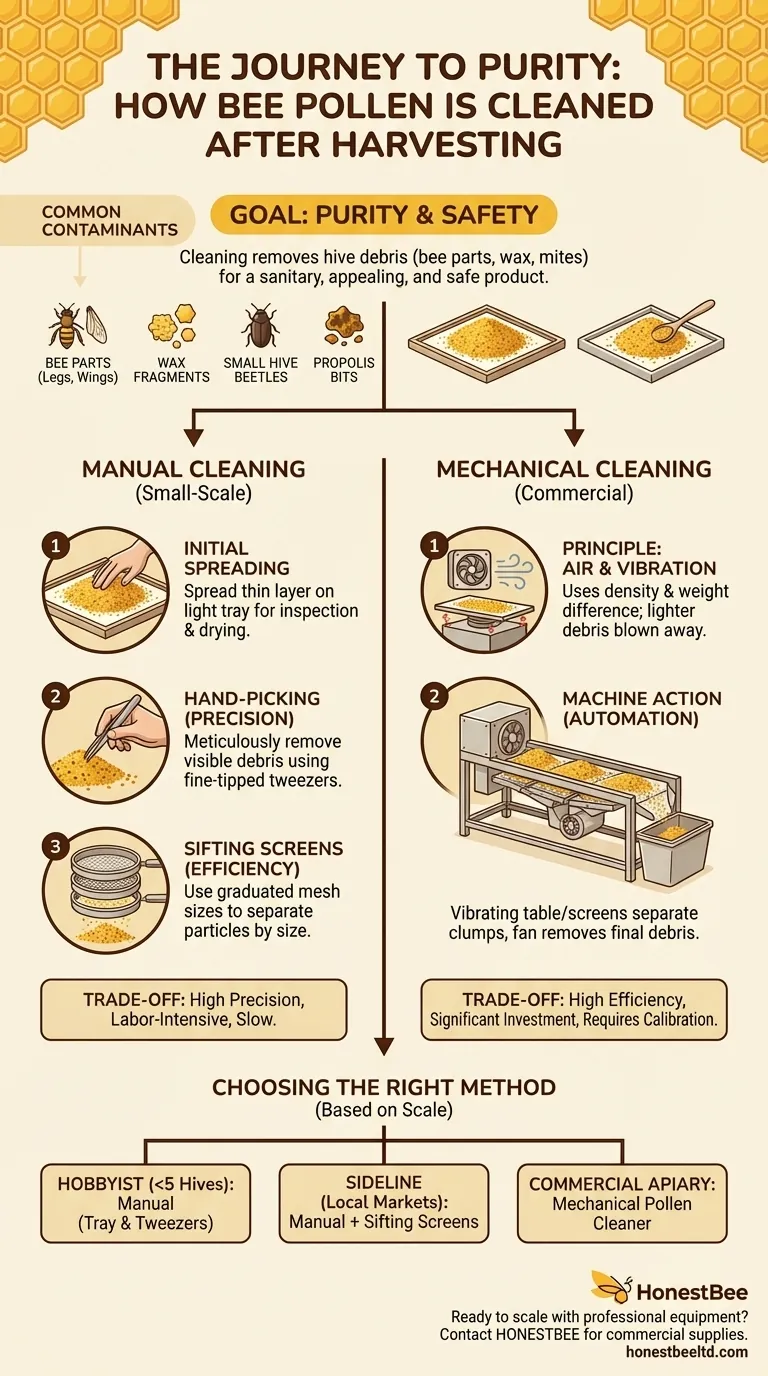

At its core, cleaning bee pollen is a meticulous process of separating the valuable pollen granules from inevitable hive debris. For small-scale operations, this involves spreading the harvest on a tray and manually removing contaminants like bee parts or wax. Commercial producers, however, rely on specialized machines that use air and vibration to perform this separation efficiently, similar to equipment used for cleaning seeds.

The method you choose for cleaning pollen is determined entirely by your scale. While manual cleaning offers precision for small batches, any significant volume demands mechanical assistance to ensure both product purity and operational efficiency.

The Goal of Pollen Cleaning: Purity and Safety

Before diving into the methods, it's critical to understand why this step is non-negotiable. The goal is to produce a safe, pure, and appealing final product for consumption.

Why Cleaning is Essential

Pollen traps inevitably collect more than just pollen. Debris from the hive environment, including bee parts, wax, and mites, will be mixed in with your harvest. Cleaning removes these contaminants, ensuring the product is sanitary and visually appealing to the end consumer.

Common Contaminants to Remove

During the cleaning process, you will be looking for and removing specific types of debris. These most commonly include bee legs, wings, antennae, small hive beetles, fragments of beeswax, and bits of propolis.

Manual Cleaning: The Small-Scale Method

For hobbyists or small-scale beekeepers, manual cleaning is the most direct and cost-effective approach. It requires patience and a good eye for detail.

Step 1: Initial Spreading and Inspection

Begin by spreading the freshly harvested pollen in a thin, single layer. Use a clean, flat tray, preferably with a light-colored surface to make contaminants easier to spot. This initial spread also helps the pollen begin to dry.

Step 2: The Art of Hand-Picking

With the pollen spread out, meticulously pick out all visible debris. A pair of fine-tipped tweezers is an invaluable tool for this task, allowing you to remove tiny fragments without disturbing the surrounding pollen granules. Good lighting is essential.

Step 3: Using Sifting Screens

To improve efficiency, you can use a series of screens with different mesh sizes. Start with a larger mesh to catch big debris like bees, then move to finer screens to separate smaller particles and dust, leaving you with cleaner pollen for the final hand-picking stage.

Mechanical Cleaning: The Commercial Solution

When harvesting pollen from dozens or hundreds of hives, manual cleaning becomes impractical. Commercial operations use specialized equipment to automate the process.

The Principle: Air and Vibration

Mechanical pollen cleaners operate on the simple principle of density and weight. The machinery uses a controlled fan to blow air across the pollen. Lighter materials like bee wings and dust are blown away, while the heavier, denser pollen granules are left behind.

How Pollen Cleaners Work

This equipment typically consists of a vibrating, tilted table or a series of oscillating screens. As the pollen moves across the vibrating surface, agitation helps to separate clumps and dislodge debris. The integrated fan then performs the final separation, ensuring a clean product falls into a collection bin.

Understanding the Trade-offs

Neither method is perfect; each comes with its own set of advantages and disadvantages that are important to weigh.

Manual Cleaning: Precision vs. Time

Hand-picking offers the highest degree of precision. You can ensure every last piece of debris is removed. However, this method is extremely slow and labor-intensive, making it completely unscalable for a growing business.

Mechanical Cleaning: Efficiency vs. Investment

A pollen cleaner is a game-changer for efficiency, processing large volumes of pollen in a fraction of the time it would take to do manually. The trade-off is the significant upfront financial investment in the equipment and the need for proper calibration to avoid losing good pollen along with the debris.

Choosing the Right Method for Your Harvest

Your decision should be based directly on the size of your operation and your ultimate goal for the product.

- If you are a hobbyist with one or two hives: Manual cleaning on a tray with tweezers is the most practical and cost-effective approach.

- If you are a sideline beekeeper selling at local markets: Consider a set of sifting screens to dramatically speed up your manual process before a final hand-inspection.

- If you are operating a commercial apiary: A dedicated mechanical pollen cleaner is an essential investment for achieving consistent quality and managing labor costs.

Ultimately, a pure and professionally presented product is the hallmark of a careful beekeeper and the foundation of customer trust.

Summary Table:

| Method | Best For | Key Process | Key Consideration |

|---|---|---|---|

| Manual Cleaning | Hobbyists, Small-scale (<5 hives) | Hand-picking debris with tweezers; using sifting screens | High precision but very time-consuming and labor-intensive |

| Mechanical Cleaning | Commercial Apiaries, Sideline Beekeepers | Uses air and vibration to separate pollen from debris | High efficiency but requires a significant upfront investment |

Ready to scale your pollen harvesting operation with professional-grade equipment?

As HONESTBEE, we specialize in supplying durable and efficient beekeeping supplies and equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable tools you need to maintain product purity and maximize your operational efficiency.

Contact HONESTBEE today to discuss your commercial beekeeping equipment needs and request a wholesale catalog!

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- 10L Stainless Steel Electric Honey Press Machine

- Professional Multi-Function Uncapping Fork with Integrated Blade for Beekeeping

- Professional Stainless Steel Uncapping Fork with Wooden Handle

People Also Ask

- How do industrial-grade pollen collectors ensure that honey yield is not compromised? Expert Beekeeping Equipment Guide

- What are the best practices for packaging and storing bee pollen? Expert Tips for Maximum Freshness and Shelf Life

- How is a high-temperature muffle furnace utilized in the determination of ash content in bee pollen? Expert Analysis

- What is a pollen trap and how does it work? A Guide to Harvesting Bee Pollen

- Why is it necessary for commercial apiaries to establish a pollen reference library? Secure Your Honey's Market Value

- What is the role of Pollen Traps in the collection process? Maximize Your Apiary's Pure Pollen Yield

- What are the advantages of heat pump drying technology? Preserve Nutrients & Quality in Bee Pollen

- What factors should beekeepers be cautious about when collecting bee pollen? Ensure Colony Health and Product Purity