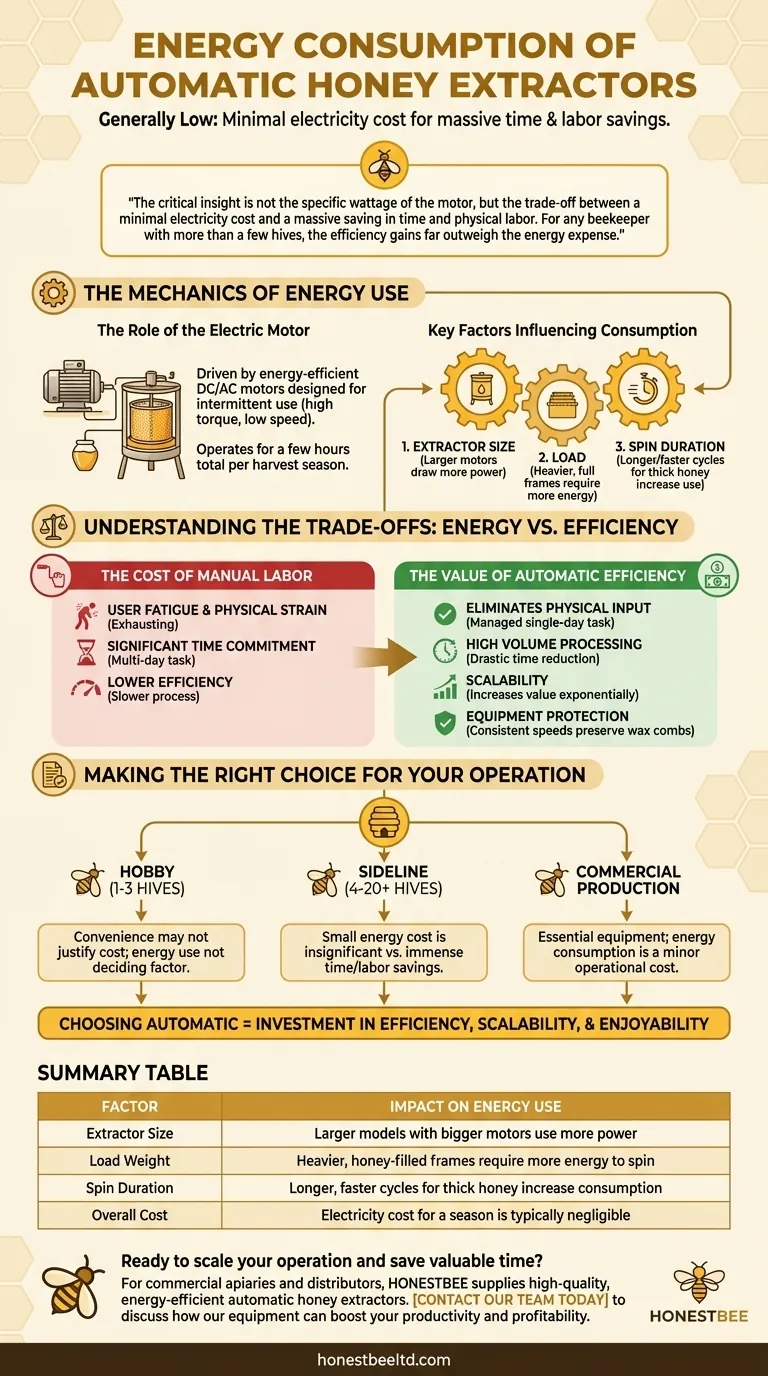

In short, the energy consumption of an automatic honey extractor is generally low. Most modern units are equipped with energy-efficient motors designed for intermittent use. While larger extractors capable of holding more frames will draw more power, the overall electricity cost for a typical beekeeper's extraction season is almost always negligible.

The critical insight is not the specific wattage of the motor, but the trade-off between a minimal electricity cost and a massive saving in time and physical labor. For any beekeeper with more than a few hives, the efficiency gains far outweigh the energy expense.

The Mechanics of Energy Use

An automatic extractor's energy consumption is straightforward, driven almost entirely by its electric motor. Understanding the factors that influence this consumption helps place the cost in the proper context.

The Role of the Electric Motor

The core of the machine is a variable-speed electric motor. Manufacturers typically select energy-efficient DC or AC motors designed to provide high torque at low speeds, which is ideal for starting a spin cycle with heavy, honey-filled frames.

These motors are not like a refrigerator or air conditioner that runs continuously. They operate for a few minutes at a time, for a total of a few hours over the entire honey harvest season.

Key Factors Influencing Consumption

Several variables determine the exact amount of power an extractor will use during an extraction session:

- Extractor Size: The primary factor. A 4-frame extractor has a smaller motor than a 20-frame radial extractor because it has less mass to spin.

- Load: A full load of heavy, uncapped frames requires more energy to start spinning than a lighter or partial load.

- Spin Duration: Longer and faster spin cycles, necessary for thick honey, will naturally consume more electricity.

Understanding the Trade-offs: Energy vs. Efficiency

Focusing solely on electricity cost misses the entire purpose of an automatic extractor. The decision to use one is an economic calculation where your own time and physical well-being are the most valuable assets.

The Cost of Manual Labor

A manual, hand-crank extractor requires significant and sustained physical effort. This "cost" is measured in user fatigue, physical strain, and the sheer amount of time spent cranking. An automatic extractor eliminates this physical input entirely.

The Value of Time and Scale

Automatic extractors are built for efficiency. They can process a high volume of frames quickly and consistently, drastically reducing the time it takes to complete a harvest. As the scale of your operation grows, the value of this saved time increases exponentially.

For a beekeeper managing dozens of hives, spending days manually cranking is not a viable option. The automatic extractor turns a multi-day, exhausting job into a manageable, single-day task.

The Impact on Your Harvest

The programmable, consistent speeds of an automatic extractor can also protect your equipment. A proper ramp-up speed reduces the risk of "blowing out" new or delicate wax combs, preserving them for the bees to use again. This protects your investment in your frames and saves the bees significant energy.

Making the Right Choice for Your Operation

The decision to go automatic should be based on the scale of your beekeeping and how you value your time.

- If your primary focus is hobby beekeeping (1-3 hives): The convenience of an automatic extractor may not justify its purchase price, and the minimal energy use is not a deciding factor.

- If your primary focus is growing a sideline business (4-20+ hives): The small energy cost is an insignificant trade-off for the immense savings in time and labor you will gain.

- If your primary focus is commercial production: An automatic extractor is essential equipment, and its energy consumption is a minor and expected operational cost.

Ultimately, choosing an automatic extractor is an investment in making your beekeeping more efficient, scalable, and enjoyable.

Summary Table:

| Factor | Impact on Energy Use |

|---|---|

| Extractor Size | Larger models with bigger motors use more power. |

| Load Weight | Heavier, honey-filled frames require more energy to spin. |

| Spin Duration | Longer, faster cycles for thick honey increase consumption. |

| Overall Cost | Electricity cost for a season is typically negligible. |

Ready to scale your operation and save valuable time? For commercial apiaries and beekeeping equipment distributors, the efficiency gains from an automatic extractor far outweigh its minimal energy cost. HONESTBEE supplies high-quality, energy-efficient automatic honey extractors and other essential beekeeping supplies through our wholesale-focused operations. Contact our team today to discuss how our equipment can boost your productivity and profitability.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- How should a centrifuge honey extractor be properly handled and maintained? 5 Essential Care Tips for Longevity

- How does a honey extractor improve the efficiency of the honey harvesting process? Maximize Your Yield and Purity

- How does a V-belt transmission system allow a honey extractor to adapt to different viscosities? Optimize Your Yield

- How can one minimize honey sticking to the extractor? Unlock a Cleaner, More Efficient Harvest

- What is the typical use case for tangential honey extractors? Ideal for Small-Scale Beekeepers & Hobbyists

- Why is it important to dry a honey extractor before storage? Prevent Mold, Protect Bees, & Extend Equipment Life

- How does a honey extractor work? Efficiently Harvest Honey While Preserving Comb

- What are the core functions of an industrial 12-frame honey extractor? Boost Efficiency and Hive Resource Conservation