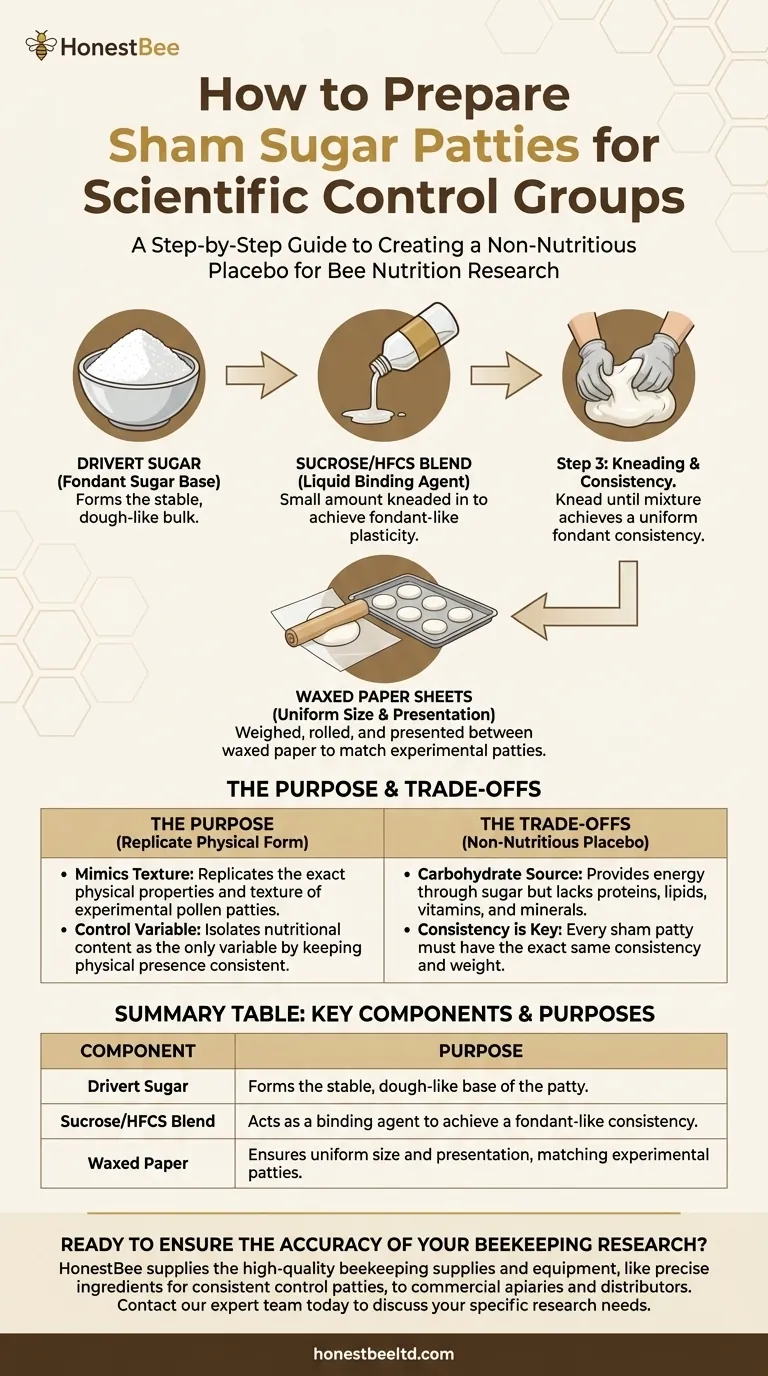

To prepare the sham sugar patties, Drivert sugar was used as the base. A small amount of a 50:50 blend of sucrose and high-fructose corn syrup (HFCS) was kneaded into the Drivert sugar. This process continued until the mixture achieved the consistency of fondant, after which the patties were weighed and rolled between sheets of waxed paper.

The core objective was to create a non-nutritious placebo that mimicked the exact physical form and texture of the experimental pollen patties. This ensures that any observed differences in bee behavior or health could be attributed to the nutritional content of the pollen, not the physical presence of a food patty.

The Purpose of the Sham Patty Design

To create an effective control in a scientific study, every variable except the one being tested must be kept consistent. In this case, the variable is the nutritional pollen substitute, so the control (the sham patty) needed to replicate its physical properties without providing the same nutrition.

Key Ingredient: Drivert Sugar

Drivert sugar, a type of finely powdered fondant sugar, serves as the bulk of the patty. Its key characteristic is its ability to form a stable, dough-like consistency without dissolving completely, making it ideal for creating a solid patty.

The Binder: Sucrose/HFCS Blend

A small amount of a liquid sugar blend (sucrose and HFCS) was kneaded in. This blend acts as a binding agent, giving the dry Drivert sugar the plasticity needed to form a cohesive, fondant-like patty. This ensured the texture was similar to the real pollen patties.

The Packaging: Waxed Paper

The patties were rolled between waxed paper sheets. This was done to match the size and presentation of the actual pollen substitute patties being tested. It prevents the bees' response from being influenced by differences in how the food was delivered.

Understanding the Trade-offs

Using a sham patty is a standard practice in bee nutrition research, but it's important to understand the limitations and considerations of this specific formulation.

Why Not Just Plain Sugar?

Simply providing granulated sugar would not replicate the physical form of a pollen patty. Bees might interact with a loose pile of sugar differently than a solid patty, introducing an unwanted variable and compromising the experiment's integrity.

Potential for Minimal Nutritional Impact

While designed to be a non-nutritious placebo, the patty is still made of sugar. The small amount of sucrose/HFCS provides carbohydrates, which are a source of energy. However, it completely lacks the proteins, lipids, vitamins, and minerals found in pollen, which is the crucial distinction for the study.

Consistency is Crucial

The most significant challenge is ensuring every sham patty has the exact same consistency and weight as the experimental patties. Any variation could influence how easily the bees consume it, thereby skewing the results of the study.

Applying This to Your Research

When designing an experiment involving bee nutrition, the control group is as important as the experimental group. The goal is to isolate the variable you are testing.

- If your primary focus is testing a protein source: A sham patty made of carbohydrates, like the one described, is the ideal control.

- If your primary focus is testing a carbohydrate supplement: Your control patty should contain only the protein and lipid components, with no added carbohydrates. -- If your primary focus is evaluating consumption preference: You must ensure all patties (control and experimental) have identical texture, size, and moisture content.

Ultimately, a well-designed sham control is essential for producing reliable and scientifically valid conclusions.

Summary Table:

| Component | Purpose |

|---|---|

| Drivert Sugar | Forms the stable, dough-like base of the patty. |

| Sucrose/HFCS Blend | Acts as a binding agent to achieve a fondant-like consistency. |

| Waxed Paper | Ensures uniform size and presentation, matching experimental patties. |

Ready to ensure the accuracy of your beekeeping research?

HONESTBEE supplies the high-quality beekeeping supplies and equipment—like the precise ingredients needed for creating consistent control patties—to commercial apiaries and distributors. Ensure your experiments are built on a foundation of reliability.

Contact our expert team today to discuss your specific research needs and how we can support your work with the right tools.

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Automatic Honey Flow Beehive 4 Frame Mini Hive for Beekeeping

- Queen Bee Catcher Plastic Bee Marker Bottle with Piston Marking Tube

- Premium Traditional Copper Bee Smoker with Bellows

- Wooden Bee Brush with Double-Row Horsehair Bristles

People Also Ask

- What is the proper method for installing a cam buckle strap on a beehive? Secure Your Hives for Maximum Stability

- What is the best length for straps used around beehives? Why 12 Feet is the Industry Standard

- How can a beehive be physically secured against harsh winter weather? Expert Winterizing Strategies for Your Apiary

- What are the two styles of hive straps? Choose the Right Strap for Your Hive Security

- What are the types of Emlocks available? Choose the Right Strap for Hive Security