The primary advantage of a top bar hive for wax production is its harvesting method. Unlike frame-based hives, where honey is extracted and the comb is reused, harvesting from a top bar hive involves removing and crushing the entire honeycomb. This process inherently separates the honey from the wax, yielding a significant and consistent supply of beeswax as a valuable co-product.

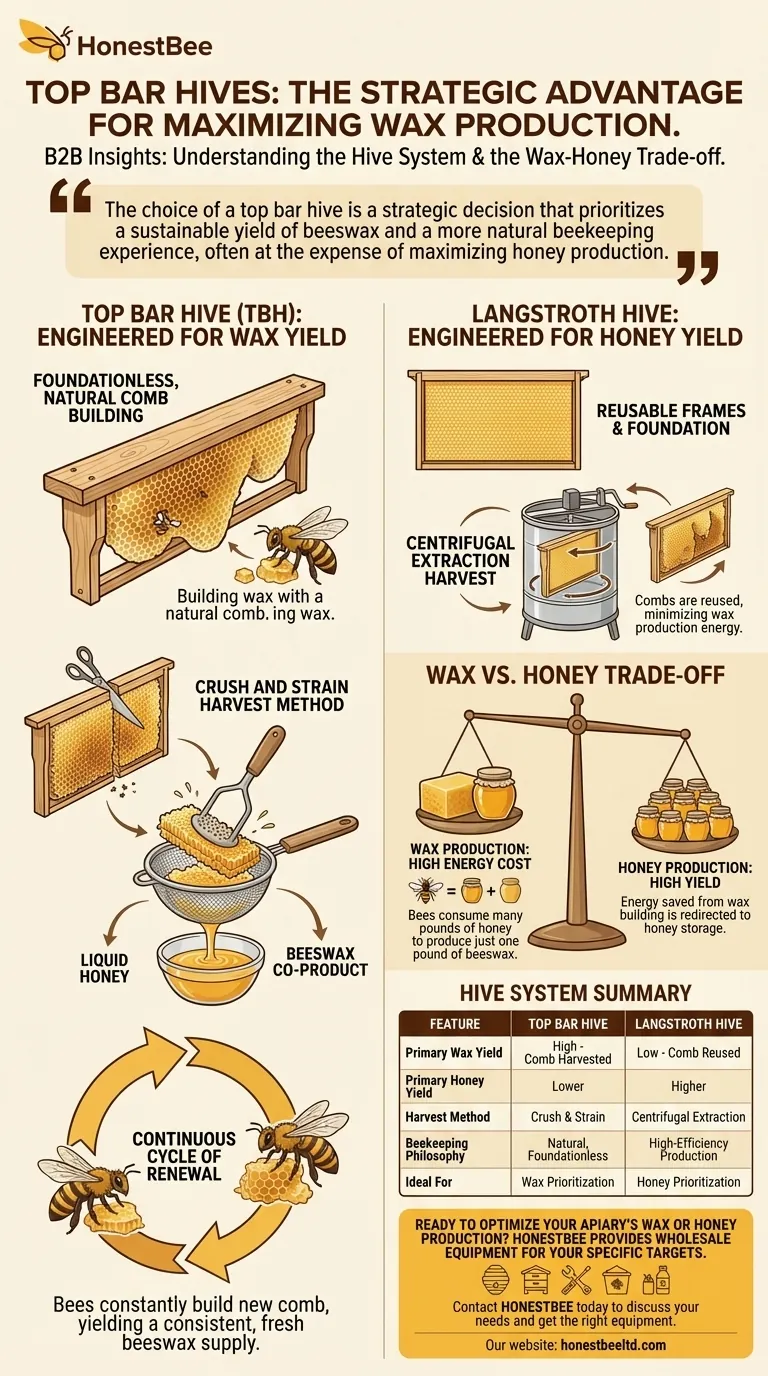

The choice of a top bar hive is a strategic decision that prioritizes a sustainable yield of beeswax and a more natural beekeeping experience, often at the expense of maximizing honey production. Understanding this fundamental trade-off is key to selecting the right hive for your goals.

The Core Mechanism: Why Top Bar Hives Yield More Wax

The design and management philosophy of a top bar hive (TBH) directly results in a higher output of beeswax compared to conventional Langstroth hives. This is not an accident but a direct consequence of its foundationless, single-use comb system.

Foundationless, Natural Comb Building

In a TBH, bees are given a simple wooden "top bar," often with a guide, but no pre-made wax or plastic foundation. The bees must draw out and build their entire comb from scratch, using their own naturally produced wax.

This practice is central to the "natural beekeeping" ethos often associated with these hives.

The "Crush and Strain" Harvest Method

When you harvest honey from a TBH, you physically cut the entire comb from the top bar. This comb, full of honey, is then mashed or crushed to break open the wax cells.

The resulting mixture is strained, typically through cheesecloth, to separate the liquid honey from the solid beeswax. The wax is what's left over.

A Continuous Cycle of Renewal

Because the comb is removed and processed during every harvest, the bees must constantly build new comb to store their next batch of honey and pollen.

This perpetual cycle of comb construction is what guarantees the beekeeper a recurring supply of fresh, clean beeswax.

Understanding the Trade-offs: Wax vs. Honey Production

The high yield of beeswax from a top bar hive comes with a significant and predictable trade-off: a lower potential for honey production compared to a Langstroth hive.

The Energy Cost of Wax

Producing wax is an incredibly energy-intensive process for honey bees. It is estimated that bees consume many pounds of honey or nectar to produce just one pound of beeswax.

In a TBH, this energy is constantly being expended to rebuild the harvested comb.

The Impact on Honey Yield

In a Langstroth hive, combs are preserved by using a centrifugal extractor to spin the honey out. Since the bees don't have to rebuild the comb, they can redirect their energy exclusively toward foraging and storing more honey.

This makes Langstroth hives far more efficient for maximizing honey output. The energy that TBH bees use for wax production is instead used for honey storage in a Langstroth hive.

The Equipment Factor

The trade-off also extends to equipment and cost. The TBH "crush and strain" method requires only basic kitchen utensils like a knife and a bowl.

In contrast, preserving comb in a Langstroth system requires an expensive honey extractor, adding a significant cost and complexity for the beekeeper.

Making the Right Choice for Your Goal

Your beekeeping objectives should dictate your choice of hive. There is no single "best" system, only the one that best aligns with your priorities.

- If your primary focus is a sustainable supply of beeswax: The top bar hive is the ideal choice, as its harvest process naturally yields wax as a core product.

- If your primary focus is maximizing honey production: A Langstroth hive is the more effective system because reusing comb allows bees to dedicate their energy to honey storage.

- If your primary focus is low startup cost and less physically demanding management: The top bar hive offers a simpler, more affordable, and ergonomic entry into beekeeping.

Ultimately, choosing a hive is a matter of deciding whether you want to manage bees for honey, for wax, or for a balanced, naturalistic experience.

Summary Table:

| Feature | Top Bar Hive | Langstroth Hive |

|---|---|---|

| Primary Wax Yield | High (Comb is harvested) | Low (Comb is reused) |

| Primary Honey Yield | Lower (Energy spent on wax) | Higher (Energy focused on honey) |

| Harvest Method | Crush and Strain | Centrifugal Extraction |

| Beekeeping Philosophy | Natural, Foundationless | High-Efficiency Production |

| Ideal For | Beekeepers prioritizing wax | Beekeepers prioritizing honey |

Ready to optimize your apiary's wax or honey production?

The right equipment is crucial for achieving your beekeeping goals. Whether you manage a commercial apiary focused on high wax yields or are a distributor supplying beekeepers, HONESTBEE has the wholesale supplies and equipment you need.

We provide durable, high-quality top bar hives, Langstroth components, and essential harvesting tools to support your operation's success and profitability.

Contact HONESTBEE today to discuss your wholesale needs and get the right equipment for your specific production targets.

Visual Guide

Related Products

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How is honey harvested from a top-bar hive? A Guide to Simple, Low-Equipment Processing

- How is honey harvested from a top bar hive? Master the Simple Crush & Strain Method

- What are the advantages of harvesting honey from a top bar hive? Low-Cost, Simple Harvesting for Beekeepers

- What is the quickest method to harvest honey from a top bar hive? A Guide to the Simple 'Cut and Crush' Method

- Why are hive inspections easier with Top Bar Hives? Achieve a Calmer, Safer Approach to Beekeeping