The primary advantages of honey processing equipment are its ability to enhance operational efficiency, ensure product quality and purity, and provide a cost-effective, hygienic solution for producers. This equipment streamlines critical processes like filtering, moisture removal, and blending into a single, controlled system, leading to a safer, more consistent, and more valuable final product.

Investing in specialized honey processing equipment is about transforming a variable, labor-intensive craft into a standardized, efficient, and commercially viable operation. It provides precise control over the factors that define honey quality, from purity to moisture content.

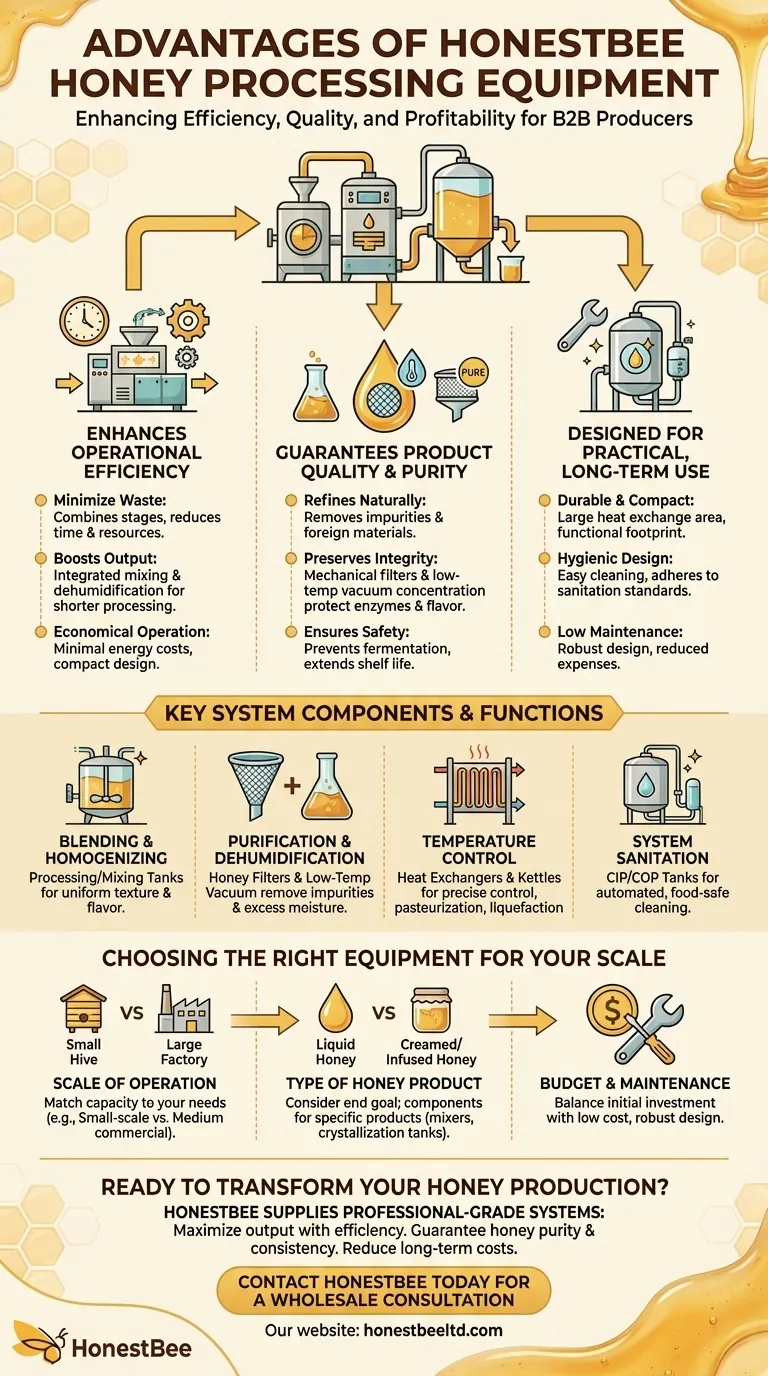

Why Specialized Equipment is a Game-Changer

Modern honey processing equipment addresses the core challenges that producers, especially small and medium-sized enterprises, face. It replaces manual, inconsistent methods with a system designed for predictable, high-quality results.

Enhances Operational Efficiency

Specialized equipment is engineered to minimize waste in both time and resources. It combines multiple processing stages, such as mixing and dehumidification, into a single plant.

This integration dramatically shortens the overall processing time and boosts output. The design focuses on economical operation, leading to minimal energy costs.

Guarantees Product Quality and Purity

The equipment's central function is to refine and protect the natural qualities of the honey. It effectively removes impurities and foreign materials that can compromise the final product.

Using mechanical filters and low-temperature vacuum concentration, the system purifies the honey and removes excess water without degrading its natural enzymes or flavor. This ensures a pure, safe, and stable product for consumers.

Designed for Practical, Long-Term Use

The physical design of this equipment prioritizes functionality and durability. It often features a compact footprint with a large surface area for heat exchange, making it efficient even in limited spaces.

Furthermore, a hygienic design is a key advantage, allowing for convenient cleaning and maintenance. This adherence to sanitation standards is critical for food safety and preventing contamination between batches.

Key Components and Their Functions

A honey processing system is composed of several specialized parts, each designed for a specific stage of the process. Understanding these components clarifies how the system achieves its results.

For Blending and Homogenizing

Processing and mixing tanks are used to blend different batches of honey or homogenize a single batch for a consistent texture and flavor profile. These tanks ensure a uniform product.

For Purification and Dehumidification

Honey filter machines are crucial for removing physical impurities like wax particles. Systems may also include low-temperature vacuum equipment to gently remove excess moisture, which is vital for preventing fermentation and increasing shelf life.

For Temperature Control

Heat exchangers and kettles allow for precise control over the honey's temperature. This is used for liquefaction, pasteurization, or preparing the honey for crystallization, all while preserving its delicate properties.

For System Sanitation

Clean-in-place (CIP) and clean-out-of-place (COP) tanks are fundamental to maintaining hygiene. They automate or simplify the cleaning process, ensuring the entire system meets strict food safety standards and is ready for the next run.

Choosing the Right Equipment for Your Scale

While the advantages are clear, selecting the wrong equipment can lead to inefficiency and unnecessary expense. The key is to match the system to the specific needs of your operation.

The Scale of Your Operation

The required capacity and throughput are the most important factors. A small-scale beekeeper has vastly different needs than a medium-sized commercial producer.

Choosing equipment that is too large results in wasted energy and capital, while a system that is too small creates a production bottleneck.

The Type of Honey Product

Consider your end goal. Are you producing simple liquid honey, or will you be creating creamed honey, infused honey, or other value-added products?

Different products require different components, such as specialized mixers or crystallization tanks. Customization is often possible with various valves, fittings, pumps, and instrumentation to meet specific needs.

Budget and Maintenance Costs

The initial investment is only part of the equation. Look for equipment with a reputation for low cost and low maintenance expenses.

A simpler, robust design may be more advantageous in the long run than a complex system that requires specialized and costly upkeep.

Making the Right Choice for Your Operation

Ultimately, the goal is to choose a system that aligns perfectly with your business objectives.

- If your primary focus is scaling up production: Prioritize a system with high efficiency and integrated functions that reduce manual labor and processing time.

- If your primary focus is premium quality and safety: Invest in equipment with advanced filtering, moisture removal, and excellent hygienic design (CIP/COP capabilities).

- If your primary focus is versatility: Seek a modular or customizable system with a range of tanks and fittings that can adapt to different honey products.

By carefully matching the equipment to your operational scale and product goals, you ensure both the quality of your honey and the long-term health of your business.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Operational Efficiency | Shortens processing time, boosts output, and reduces energy costs. |

| Product Quality & Purity | Removes impurities and controls moisture without degrading natural enzymes. |

| Practical & Hygienic Design | Compact, durable, and easy to clean with CIP/COP systems for food safety. |

Ready to transform your honey production?

HONESTBEE supplies professional-grade honey processing equipment designed for commercial apiaries and beekeeping equipment distributors. Our systems are engineered to:

- Maximize your output with integrated, efficient designs.

- Guarantee honey purity and consistency for a premium product.

- Reduce long-term costs with durable, low-maintenance equipment.

Let us help you choose the perfect system to scale your operation and enhance your honey's quality. Contact HONESTBEE today for a wholesale consultation!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Thermostatic Conical Honey Melter

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What is the significance of automated honey-filling machines? Scale Your Apiary with Precision and Efficiency

- What are the benefits of automated honey filling and packaging? Scale Your Apiary with Industrial Precision

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- What are the primary benefits of automated honey-filling machines? Scale Your Commercial Apiary Efficiency

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export