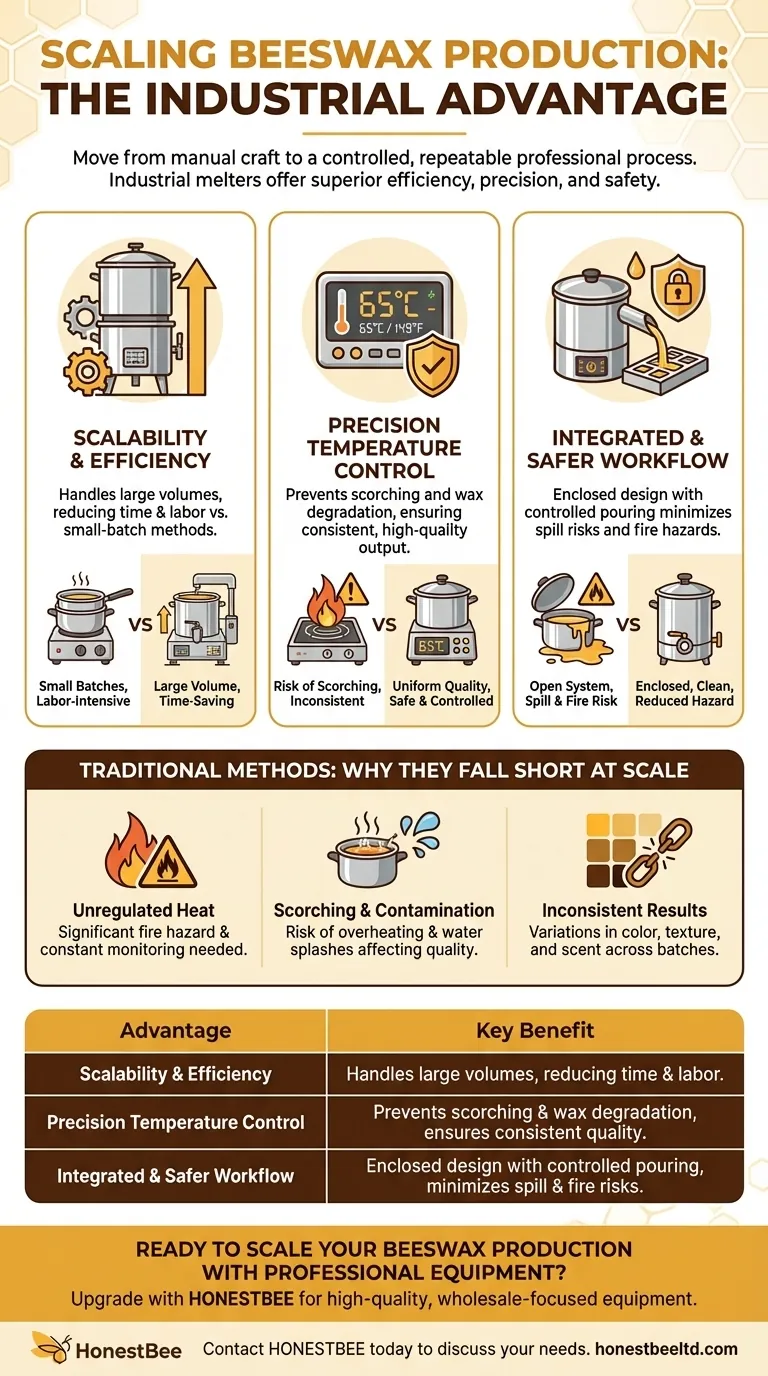

At its core, an industrial wax melter provides three critical advantages for processing beeswax: superior efficiency for large volumes, precise temperature control to prevent scorching, and a significantly safer, more streamlined workflow than traditional methods. This specialized equipment is designed to move beeswax melting from a manual craft into a controlled, repeatable manufacturing process.

The decision to use an industrial melter is less about simply melting wax and more about gaining control. It marks the transition from small-batch hobby work to a scalable, professional operation where consistency, safety, and efficiency are paramount.

The Core Advantages of Industrial Melters

When working with significant quantities of beeswax, the limitations of basic methods quickly become apparent. Industrial melters are engineered specifically to solve these challenges.

Scalability and Efficiency

Industrial melters are built to handle large quantities of wax, melting significant volumes in a single batch.

This capability drastically reduces the time and labor required compared to melting multiple small batches in double boilers or crock pots.

Precision Temperature Control

Beeswax quality degrades rapidly if overheated. An industrial melter's primary advantage is its thermostat, which maintains a precise, consistent temperature.

This prevents scorching, which can darken the wax and alter its natural scent, ensuring a uniform, high-quality product every time. It also eliminates the risk of reaching the wax's flashpoint.

Integrated and Safer Workflow

These units are designed as a single, self-contained system. They often feature heated spigots or valves for easy, controlled pouring.

This enclosed design minimizes exposure to hot surfaces and reduces the risk of dangerous spills, unlike the open pots and pans used in a double boiler setup.

Why Traditional Methods Fall Short at Scale

While effective for small projects, methods like double boilers introduce variables and risks that are unacceptable in a professional setting.

The Dangers of Unregulated Heat

Beeswax is flammable at high temperatures. Methods that rely on direct or poorly controlled indirect heat, like a pot on a stove or a crock pot, create a significant fire hazard.

The user must constantly monitor the process, as leaving the wax unattended can lead to overheating or fire.

The Risk of Scorching and Water Contamination

A double boiler requires constant attention to ensure the water does not evaporate, which could lead to a sudden temperature spike and scorch the wax.

Splashes of water can also contaminate the beeswax, affecting the quality of the final product, whether it be candles, cosmetics, or food wraps.

Inconsistent and Labor-Intensive Results

Manually managing temperature across multiple small batches is difficult and time-consuming. This often leads to variations in color, texture, and scent from one batch to the next.

This lack of consistency is a major liability for any business that relies on a repeatable, high-quality product.

Understanding the Trade-offs

While highly beneficial, investing in an industrial melter is not the right choice for every situation. Objectively weighing the costs is essential.

Significant Initial Investment

Industrial-grade equipment represents a substantial financial commitment compared to the near-zero cost of using existing kitchen equipment like a crock pot or double boiler.

Space and Power Requirements

These melters are larger and require dedicated counter or floor space. They are not small appliances that can be easily stored away.

Some larger models may also have specific electrical requirements beyond a standard wall outlet.

Maintenance and Cleaning

Proper cleaning is essential to prevent cross-contamination between different types of waxes or batches. While the process is streamlined, it still requires diligent maintenance.

Making the Right Choice for Your Operation

The ideal method for melting beeswax depends entirely on the scale and goals of your production.

- If your primary focus is small-batch hobby projects: The safety and low cost of a dedicated crock pot or double boiler are perfectly suitable and manageable.

- If your primary focus is commercial production and product consistency: Investing in an industrial wax melter is a critical step for ensuring safety, efficiency, and professional-grade quality.

Ultimately, choosing the right tool for the scale of your work is the key to producing high-quality beeswax products safely and effectively.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Scalability & Efficiency | Handles large volumes, reducing time and labor vs. small-batch methods. |

| Precision Temperature Control | Prevents scorching and wax degradation, ensuring consistent, high-quality output. |

| Integrated & Safer Workflow | Enclosed design with controlled pouring minimizes spill risks and fire hazards. |

Ready to Scale Your Beeswax Production with Professional Equipment?

Upgrade your operation with the efficiency and safety of an industrial wax melter. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused equipment needed for scalable, professional-grade production.

Contact HONESTBEE today to discuss your needs and discover the right melter for your business.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive

- What is beeswax and why is it valuable? Discover Its Versatility for Your Business

- What is the process for purifying beeswax after removing it from a hive? A Simple Two-Stage Method for Pure Wax

- Why might a commercial beekeeper prefer an electric beeswax melter? Maximize Profit with Speed & Scale

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods