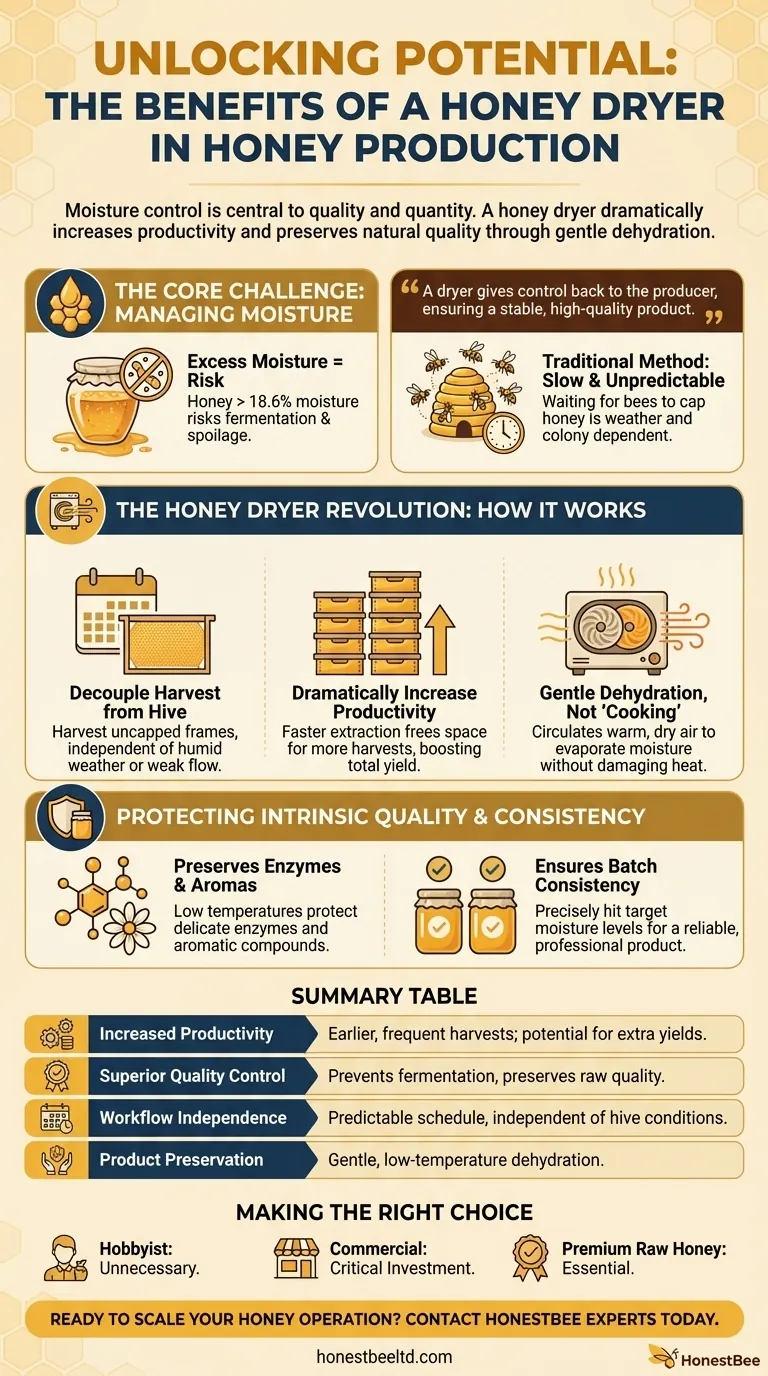

In honey production, moisture control is not just a detail—it is the central factor determining both the quality and quantity of your final product. A honey dryer, or dehumidifier, is a specialized piece of equipment designed to solve this exact problem. Its primary benefits are to dramatically increase productivity by allowing for earlier and more frequent harvests, and to preserve the honey's natural quality by gently removing excess water without the damaging effects of high heat.

The core challenge for any beekeeper is that waiting for bees to naturally dehydrate and cap honey is slow and unpredictable. A honey dryer gives control back to the producer, decoupling the harvest schedule from the hive's pace and ensuring a stable, high-quality product ready for market.

The Core Challenge: Managing Honey's Moisture Content

Why Excess Moisture Is a Problem

Honey with a moisture content above 18.6% is at risk of fermentation. The naturally occurring yeasts in honey can become active in the presence of excess water, spoiling the entire batch.

Properly dried honey is incredibly shelf-stable, but even a slightly elevated moisture level can lead to a compromised product that cannot be sold.

The Traditional Method: Waiting for the Bees

Bees are masters of dehydration. They actively fan their wings over the nectar-filled honeycomb cells to circulate air and evaporate water.

Once the moisture level is just right (typically below 18%), they seal the cell with a wax capping. This process is effective but slow, dependent on the weather, nectar flow, and the strength of the colony.

How a Honey Dryer Revolutionizes the Harvest

Decoupling Harvest from Hive Conditions

A honey dryer gives you the freedom to harvest frames that are not fully capped. This is a significant advantage in humid climates or during periods of weak nectar flow when bees struggle to finish the dehydration process.

You are no longer forced to wait for perfect hive conditions. You can pull frames when it fits your schedule, knowing you can standardize the final product back in your facility.

Dramatically Increased Productivity

By harvesting honey with a higher moisture content, you can extract it from the supers sooner. This frees up space in the hive for the bees to fill again.

For commercial operations, this can mean securing one or more extra harvests per season, directly translating to a substantial increase in total yield and revenue.

The Mechanism: Gentle Dehydration

A honey dryer does not "cook" the honey. Instead, it circulates warm, dry air over the surface of the honey, which is typically held in a shallow tank or rotating discs to maximize exposure.

This process encourages evaporation in a controlled environment, slowly and gently reducing moisture without raising the honey's temperature to a point where its delicate chemical structure is damaged. Some units can reduce moisture by 1-2% over an eight-hour period.

Protecting the Intrinsic Quality of Your Honey

Preserving Sensitive Enzymes and Aromas

Raw honey is valued for its natural enzymes (like diastase) and delicate aromatic compounds. Excessive heat destroys these components and can increase levels of HMF (hydroxymethylfurfural), an indicator of heat damage or age.

Because a honey dryer uses low temperatures, it preserves the very qualities that define a premium, raw honey product, ensuring its flavor and beneficial properties remain intact.

Ensuring Consistency Across Batches

A honey dryer allows you to precisely hit your target moisture level every single time. This consistency is crucial for creating a reliable, professional-grade product.

Whether bottling for retail or selling in bulk, a standardized product builds client trust and ensures every batch meets legal and quality standards. It's a key part of moving from a hobby to a scalable business.

Understanding the Trade-offs and Considerations

The Initial Investment

Honey dryers are specialized, professional-grade machines. The upfront cost is a significant consideration and must be weighed against the potential increase in productivity and revenue.

Operational Time and Energy

Dehydration is not an instant process. As noted, reducing moisture by just a few percentage points can take several hours. This requires planning your workflow as well as accounting for the energy costs of running the machine.

The Risk of Improper Use

While designed for gentle processing, setting the temperature too high on a dryer negates its primary benefit. Doing so can damage the honey just as much as other heating methods, turning a valuable investment into a liability. Proper training and adherence to protocols are essential.

Making the Right Choice for Your Operation

A honey dryer is a strategic tool, and its necessity depends entirely on your goals.

- If your primary focus is hobbyist beekeeping: A dryer is likely an unnecessary expense. You can afford to be patient and let the bees fully cap the honey before you harvest.

- If your primary focus is commercial production: A dryer becomes a critical investment for increasing yield, standardizing quality, and creating a predictable and efficient workflow.

- If your primary focus is premium raw honey: A dryer is essential for guaranteeing a low moisture content while simultaneously protecting the delicate enzymes and aromas that command a higher price.

Ultimately, investing in a honey dryer transforms your operation from being reactive to the hive to being in control of your production.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Increased Productivity | Enables earlier, more frequent harvests; potential for extra yields per season. |

| Superior Quality Control | Precisely lowers moisture to prevent fermentation, preserving raw honey quality. |

| Workflow Independence | Decouples harvest from hive conditions, allowing for a predictable schedule. |

| Product Preservation | Uses gentle, low-temperature dehydration to protect delicate enzymes and aromas. |

Ready to take control of your honey harvest and scale your operation?

As HONESTBEE, a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, we understand the critical role a honey dryer plays in maximizing your productivity and profit. Our range of professional-grade equipment is designed to deliver the precise moisture control and gentle processing your premium product demands.

Contact our experts today to discuss how integrating a honey dryer can transform your workflow, increase your yield, and ensure the consistent, high-quality honey your customers expect.

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?

- Why is the use of dry sieves and storage containers critical? Prevent Honey Fermentation and Spoilage

- How much honey can a honey dryer process and by what percentage does it reduce moisture? Optimize Your Honey Production

- Why is industrial-grade dehumidification equipment essential for producing commercial-standard honey? Expert Insights

- What was the process for drying lumber for beehive supers? Achieve 8-9% Moisture for Precision Joint Stability