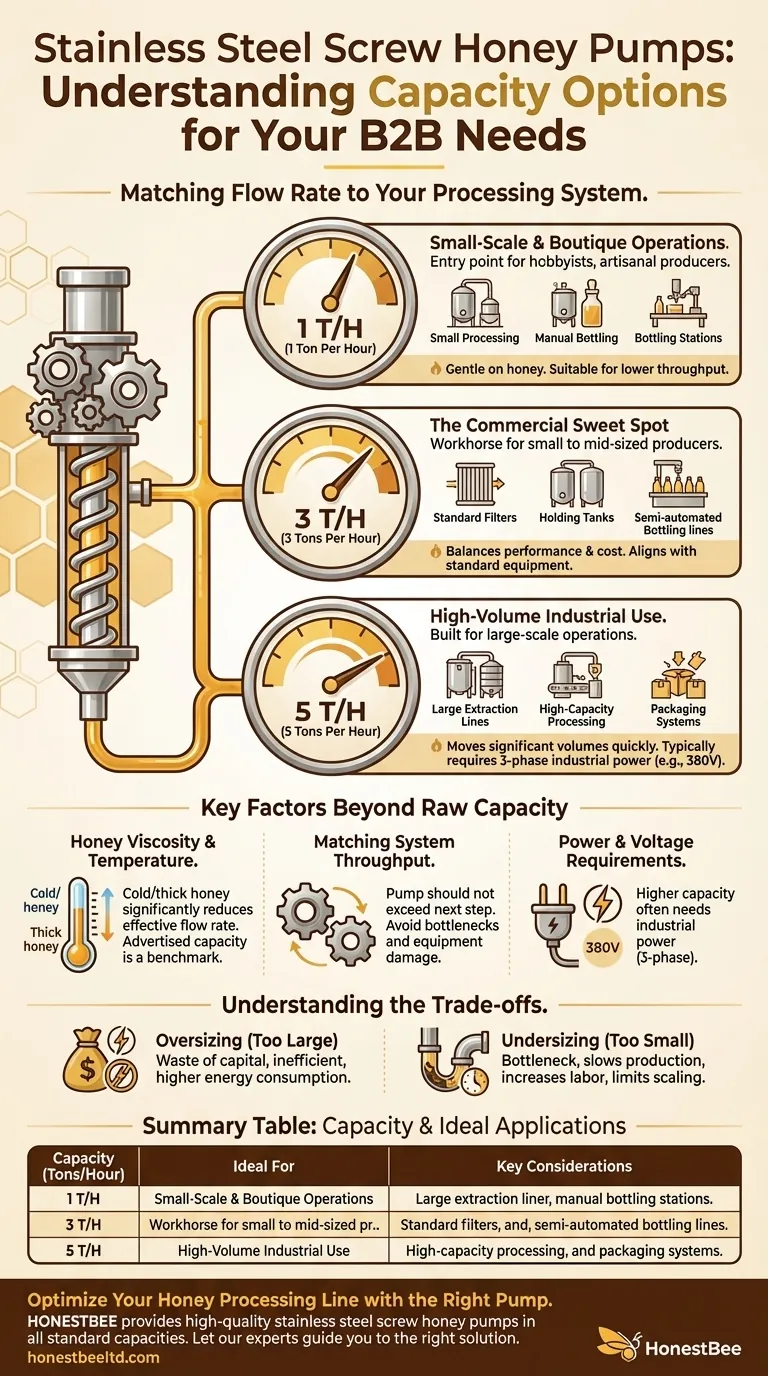

To answer your question directly, stainless steel screw honey pumps are most commonly available in three standard capacity options: 1 ton per hour (1T/H), 3 tons per hour (3T/H), and 5 tons per hour (5T/H). These ratings define the maximum volume of honey the pump can move under ideal conditions.

Choosing the right pump is less about picking the biggest number and more about matching the flow rate to your entire processing system. The goal is to create a balanced, efficient workflow that protects the quality of the honey.

Decoding Pump Capacity: What "Tons Per Hour" Means

The capacity rating is the foundational specification for a honey pump. Each size is engineered for a specific operational scale, from small apiaries to large industrial plants.

The 1 T/H Pump: For Small-Scale & Boutique Operations

This pump is the entry point for professional setups. It's designed for hobbyists with large apiaries, artisanal producers, or businesses with smaller processing tanks and equipment. Its lower flow rate is often gentler on the honey.

The 3 T/H Pump: The Commercial Sweet Spot

This is the workhorse for most small to mid-sized commercial honey producers. The 3 T/H capacity provides a significant throughput that aligns well with standard-sized filters, holding tanks, and semi-automated bottling lines.

The 5 T/H Pump: For High-Volume Industrial Use

This pump is built for large-scale operations. It's designed to move significant volumes of honey quickly, servicing large extraction lines and feeding high-capacity processing and packaging systems.

Key Factors Beyond Raw Capacity

Simply choosing a pump based on its T/H rating is a common mistake. The true performance is influenced by your specific operational conditions.

Honey Viscosity and Temperature

The advertised capacity is a benchmark. Colder, more viscous, or crystallized honey will be much harder to pump, significantly reducing the effective flow rate. A pump rated for 3 T/H might only achieve 1.5 T/H with cold, thick honey.

Matching Your System's Throughput

Your pump should not be faster than the next step in your process. A 5 T/H pump feeding a filter that can only handle 2 T/H creates a major bottleneck, wastes energy, and can damage your equipment.

Power and Voltage Requirements

Higher capacity often requires more power. While smaller pumps may run on standard single-phase 220V power, larger pumps like the 5 T/H model typically require three-phase 380V industrial power, which can be a critical infrastructure consideration.

Understanding the Trade-offs

Selecting a pump involves balancing cost, efficiency, and your future growth plans.

The Cost of Oversizing

A pump that is too large for your operation is a waste of capital. It will consume more electricity and may spend most of its time sitting idle or running inefficiently.

The Bottleneck of Undersizing

A pump that is too small will become the weak link in your entire production line. It will slow down every process, from extraction to bottling, increasing labor hours and limiting your ability to scale up.

Making the Right Choice for Your Operation

Use your current and future production goals to guide your decision.

- If your primary focus is a small-scale or boutique operation: The 1 T/H pump provides gentle handling and sufficient throughput for manual or semi-automated processes.

- If your primary focus is a growing commercial apiary: The 3 T/H pump offers the best balance of performance, cost, and scalability for most professional processing lines.

- If your primary focus is large-scale industrial processing: The 5 T/H pump is necessary to maximize efficiency and keep pace with high-volume extraction and bottling demands.

Matching the pump's capacity to your operational scale is the most critical step in building an efficient and quality-focused honey processing system.

Summary Table:

| Capacity (Tons/Hour) | Ideal For | Key Considerations |

|---|---|---|

| 1 T/H | Small-scale & Boutique Operations | Gentle handling, suitable for smaller tanks and manual processes. |

| 3 T/H | Commercial Apiaries (Sweet Spot) | Balances performance and cost; works with standard filters and bottling lines. |

| 5 T/H | High-Volume Industrial Processing | Requires industrial power (3-phase); for large extraction and packaging systems. |

Optimize Your Honey Processing Line with the Right Pump

Choosing the correct pump capacity is crucial for efficiency and protecting honey quality. As a leading supplier to commercial apiaries and distributors, HONESTBEE provides high-quality stainless steel screw honey pumps in all standard capacities. We help you select the perfect pump to match your system's throughput, avoid bottlenecks, and scale your operation effectively.

Let our experts guide you to the right solution for your needs. Contact HONESTBEE today for a consultation!

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

People Also Ask

- What role do industrial-scale mixing and pumping machines play in honey bee feeding management? Enhance Apiary Efficiency

- How does a pump filling machine work? A Guide to Precise Liquid Filling for Commercial Beekeepers

- What are the technical advantages of using syringes or electric pumps for stingless bee honey? Pure Harvest & Hive Safety

- What voltage options are available for stainless steel screw honey pumps? Choose the Right Power for Your Scale

- What is the function of a vacuum suction pump in the harvesting of stingless bee honey? Optimize Your Colony's Yield

- What advantages do specialized Suction Pumps offer compared to traditional methods? Optimize Royal Jelly Extraction

- What technical advantages do honey suction machines offer? Maximize Yield & Purity with Negative Pressure Technology

- Why use honey suction devices for stingless bees? Optimize Harvest Yield and Hive Health