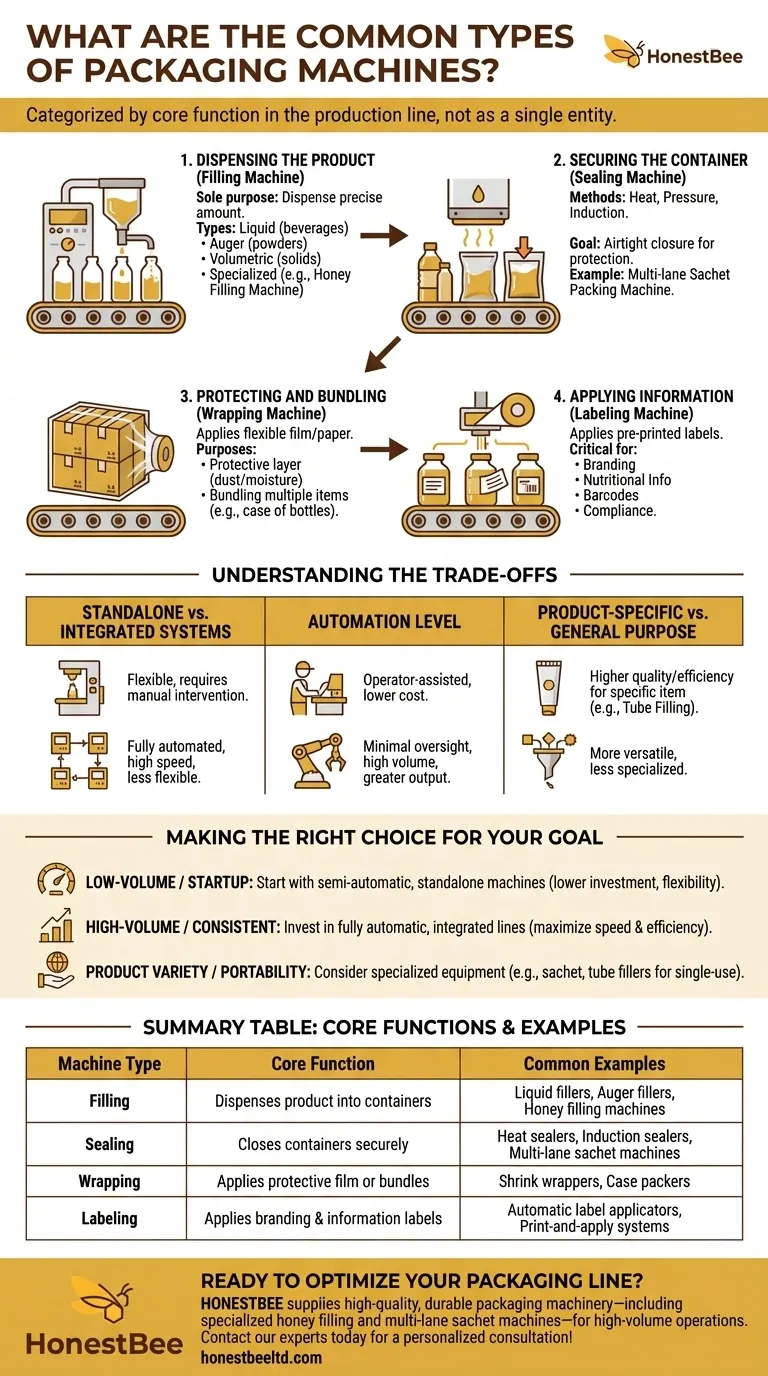

The most common types of packaging machines are categorized by their core function in the production line. These include filling machines to dispense the product, sealing machines to close the container, wrapping machines to add a protective layer, and labeling machines to apply branding and information.

The key is to see packaging machinery not as a single entity, but as a series of specialized stations in an assembly line. Each machine type performs a distinct task—from dispensing a product to sealing its container—that collectively prepares a product for the consumer.

The Core Functions of Packaging Machinery

Understanding the packaging process as a sequence of steps is the best way to understand the machinery involved. Each type of machine corresponds to a critical stage in this sequence.

Stage 1: Dispensing the Product

A filling machine is the first major step in most automated packaging lines. Its sole purpose is to dispense a precise amount of product into a container.

The type of filler depends entirely on the product's consistency. Examples include liquid fillers for beverages, auger fillers for powders, and volumetric fillers for solids like grains or snacks.

Specialized versions exist for specific products, such as honey filling machines designed to handle the viscosity of honey for jars and bottles.

Stage 2: Securing the Container

Once filled, the container must be securely closed. This is the role of a sealing machine.

Sealers use methods like heat, pressure, or induction to create an airtight closure on bags, pouches, trays, and bottles. This protects the product from contaminants and preserves freshness.

For specific applications, like creating single-serving honey pouches, a multi-lane sachet packing machine combines filling and sealing in a high-volume, automated process.

Stage 3: Protecting and Bundling

A wrapping machine applies a flexible material, like film or paper, around a product or a group of products.

This serves two purposes: providing a protective layer against dust and moisture, or bundling multiple items together for sale as a single unit (e.g., shrink-wrapping a case of water bottles).

Stage 4: Applying Information

The final functional step is handled by a labeling machine. This equipment applies pre-printed labels to containers, boxes, or products.

Labels are critical for branding, providing nutritional information, displaying barcodes, and ensuring regulatory compliance.

Understanding the Trade-offs

Choosing the right machine involves more than just identifying its function. It requires balancing efficiency, cost, and flexibility.

Standalone vs. Integrated Systems

A standalone machine, like a single sealer, offers flexibility but requires manual intervention between stages.

An integrated line connects multiple machines (e.g., a filler, sealer, and labeler) with conveyors for a fully automated process, maximizing speed but reducing flexibility for different product types.

Automation Level

Machines can be semi-automatic, requiring an operator for tasks like loading containers, or fully automatic, handling the entire process with minimal human oversight.

The choice depends on production volume. Full automation has a higher initial cost but offers significantly greater output and lower labor costs per unit.

Product-Specific Machinery

While general-purpose machines exist, many products require specialized equipment. A tube filling machine, for instance, is specifically designed to fill and seal squeeze tubes, a task a standard bottle filler cannot perform.

Investing in specialized machinery ensures higher quality and efficiency for a specific product but limits your ability to package other items.

Making the Right Choice for Your Goal

Your production needs will determine the ideal machinery configuration.

- If your primary focus is low-volume or startup production: Start with semi-automatic, standalone machines for lower initial investment and greater flexibility.

- If your primary focus is high-volume, consistent output: Invest in a fully automatic, integrated packaging line to maximize speed and efficiency.

- If your primary focus is product variety and portability: Consider specialized equipment like sachet or tube filling machines that create convenient, single-use formats.

Ultimately, selecting the right packaging machine is about matching the equipment's capabilities to your specific product, container, and production goals.

Summary Table:

| Machine Type | Core Function | Common Examples |

|---|---|---|

| Filling Machine | Dispenses product into containers | Liquid fillers, auger fillers, honey filling machines |

| Sealing Machine | Closes containers securely | Heat sealers, induction sealers, multi-lane sachet machines |

| Wrapping Machine | Applies protective film or bundles products | Shrink wrappers, case packers |

| Labeling Machine | Applies branding and information labels | Automatic label applicators, print-and-apply systems |

Ready to Optimize Your Packaging Line?

Whether you're a commercial apiary scaling honey production or a distributor sourcing reliable equipment, the right machinery is key to efficiency and profitability. HONESTBEE supplies high-quality, durable packaging machinery—including specialized honey filling machines and multi-lane sachet packing machines—tailored for high-volume, wholesale-focused operations.

Let us help you build a faster, more reliable packaging process. Contact our experts today for a personalized consultation and quote!

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic In-Line Round Bottle Labeling Machine

- Professional Durable Customizable Blister Packing Machine

- Semi Automatic Round Bottle Labeling Machine

People Also Ask

- How does a rotary honey filler work? Boost Production Efficiency with Precision Engineering

- What is the indirect impact of automated hive-making and honey-filling machines on the pollination market? Boost Stability

- What is the purpose of the film roller in a honey stick machine? Prevent Spillage & Ensure Perfect Seals

- What benefits do automated honey filling and labeling machines provide? Scale Your Commercial Honey Brand Successfully

- Why are specific moisture control and honey-filling machines required? Protect Your Harvest During Rainy Seasons

- How do industrial honey-filling machines contribute to the efficiency of the honey supply chain? Scale Your Honey Output

- Why is the use of industrial-grade automatic filling machines significant for Eucalyptus honey? Ensure Quality & Purity

- What is the significance of automatic filling equipment in bee product quality? Unlock High-Value Retail Potential