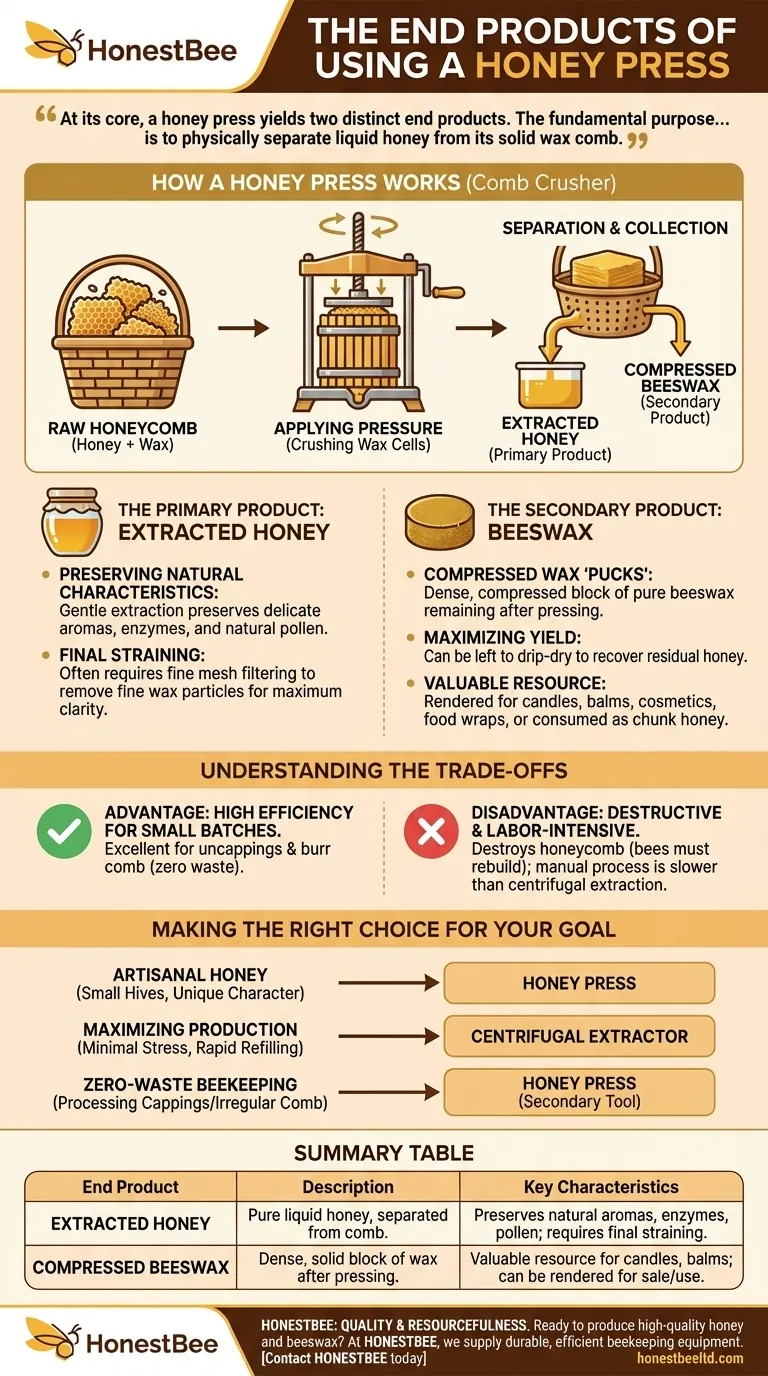

At its core, a honey press yields two distinct end products. By using mechanical pressure to crush raw honeycomb, the press efficiently separates the harvest into pure, liquid honey and a compressed block of clean beeswax.

The fundamental purpose of a honey press is to physically separate liquid honey from its solid wax comb. This simple, direct method is valued for preserving the honey's natural qualities and for its efficiency in smaller-scale beekeeping operations.

How a Honey Press Works

A honey press, also known as a comb crusher, is a straightforward mechanical device. Understanding its simple operation clarifies the nature of its end products.

The Core Mechanism

First, raw honeycomb, including uncappings or burr comb, is loaded into the press basket or sieve bucket. This material contains both the liquid honey and the wax structure that holds it.

Applying Pressure

Next, a press plate is lowered by rotating a handle. This applies steady, increasing pressure, crushing the wax cells and forcing the liquid honey out.

Separation and Collection

The liquid honey flows through perforations in the basket and is collected in a container below. The solid beeswax, now compressed, is trapped inside the basket, achieving a clean separation.

The Primary Product: Extracted Honey

The honey produced by a press is distinct from that produced by other methods, primarily due to the gentle nature of the extraction.

Preserving Natural Characteristics

Because this method does not use high-speed centrifugal force or heat, many beekeepers believe it better preserves the honey's delicate aromas, enzymes, and natural pollen content.

The Need for Final Straining

Pressed honey often contains fine wax particles. To achieve maximum clarity, it is typically poured through a fine mesh filter or cheesecloth after pressing to remove any remaining debris.

The Secondary Product: Beeswax

The wax left behind is not a waste product but a valuable secondary harvest.

Compressed Wax "Pucks"

After the honey is fully extracted, the material remaining in the press is a dense, compressed "puck" of pure beeswax.

Maximizing Yield

This compressed wax can be left on a straining setup to allow any residual honey to slowly drip out, ensuring minimal waste of the harvest.

A Valuable Resource

Once fully drained, this clean beeswax can be rendered and used for making candles, balms, cosmetics, or food wraps. Alternatively, if not fully strained, the wax and residual honey can be consumed together as chunk honey.

Understanding the Trade-offs

While effective, using a honey press involves specific advantages and disadvantages compared to other extraction methods.

Advantage: High Efficiency for Small Batches

The press is exceptionally good at recovering honey from uncappings and burr comb, areas where a centrifugal extractor is ineffective. This makes it ideal for small harvests or for beekeepers aiming for zero waste.

Disadvantage: Destructive to the Comb

The most significant trade-off is that this method destroys the honeycomb. Bees expend considerable energy to build comb, and destroying it means they must start over. Centrifugal extractors, by contrast, keep the comb intact for reuse.

Disadvantage: Labor-Intensive Process

Manually loading, pressing, and cleaning the device can be a time-consuming and labor-intensive process, especially when compared to the speed of a centrifugal extractor for larger harvests.

Making the Right Choice for Your Goal

Selecting a honey press depends entirely on your beekeeping philosophy, scale, and desired outcome.

- If your primary focus is producing artisanal honey from a small number of hives: A honey press is an excellent choice for preserving the honey's unique character and utilizing every part of the harvest.

- If your primary focus is maximizing honey production with minimal stress on the bees: A centrifugal extractor is superior, as it allows you to return empty, intact comb to the hive for rapid refilling.

- If your primary focus is zero-waste beekeeping: A honey press is an invaluable secondary tool for processing the cappings and irregular comb that a primary extractor cannot handle.

Ultimately, a honey press is a powerful tool for the beekeeper who values quality and resourcefulness over sheer volume and speed.

Summary Table:

| End Product | Description | Key Characteristics |

|---|---|---|

| Extracted Honey | Pure liquid honey separated from the crushed comb. | Preserves natural aromas, enzymes, and pollen; may require final straining. |

| Compressed Beeswax | A dense, solid block of wax left after pressing. | A valuable resource for candles, balms, or cosmetics; can be rendered for sale or use. |

Ready to produce high-quality honey and beeswax for your commercial apiary or distribution business?

A honey press is an essential tool for beekeepers focused on artisanal quality and zero-waste operations. At HONESTBEE, we supply durable, efficient beekeeping equipment to commercial apiaries and distributors through our wholesale-focused operations.

Contact HONESTBEE today to discuss how our honey presses and other supplies can enhance your harvest and maximize your product yield.

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are the multipurpose uses of a honey press? Boost Your Farm's Efficiency with One Tool

- What is a honey press used for? A Simple Guide to Crush-and-Strain Extraction

- What material is the honey-wax separating screw press constructed from? Premium Acid-Proof Stainless Steel Guide

- What is the recommended cleaning process for a honey press? Pro Tips for Wax Removal and Hygiene

- What are the product advantages of honey pressing vs centrifugal extraction? Unlock Superior Artisanal Quality

- Can a honey press be used for other purposes? 3 Versatile Uses for Beekeepers and Hobbyists

- What is a honey press and what is its purpose? Maximize Honey & Wax Yield from Your Hives

- How does pressing honey help preserve its quality? Retain Rich Flavors and Nutrients Through Low-Aeration Extraction