At its core, a honey processing machine is a system of integrated components designed to take raw honey from the comb and turn it into a pure, consistent, and market-ready product. The key components include an extractor for separating honey, a filtration system for removing impurities, a heating element for improving fluidity, a homogenizer for ensuring uniform texture, and an automated packaging unit for bottling.

A honey processing machine is best understood not as a single device, but as a sequential production line. Each component performs a distinct function, working in concert to efficiently extract, purify, and package honey while maintaining strict quality and hygiene standards.

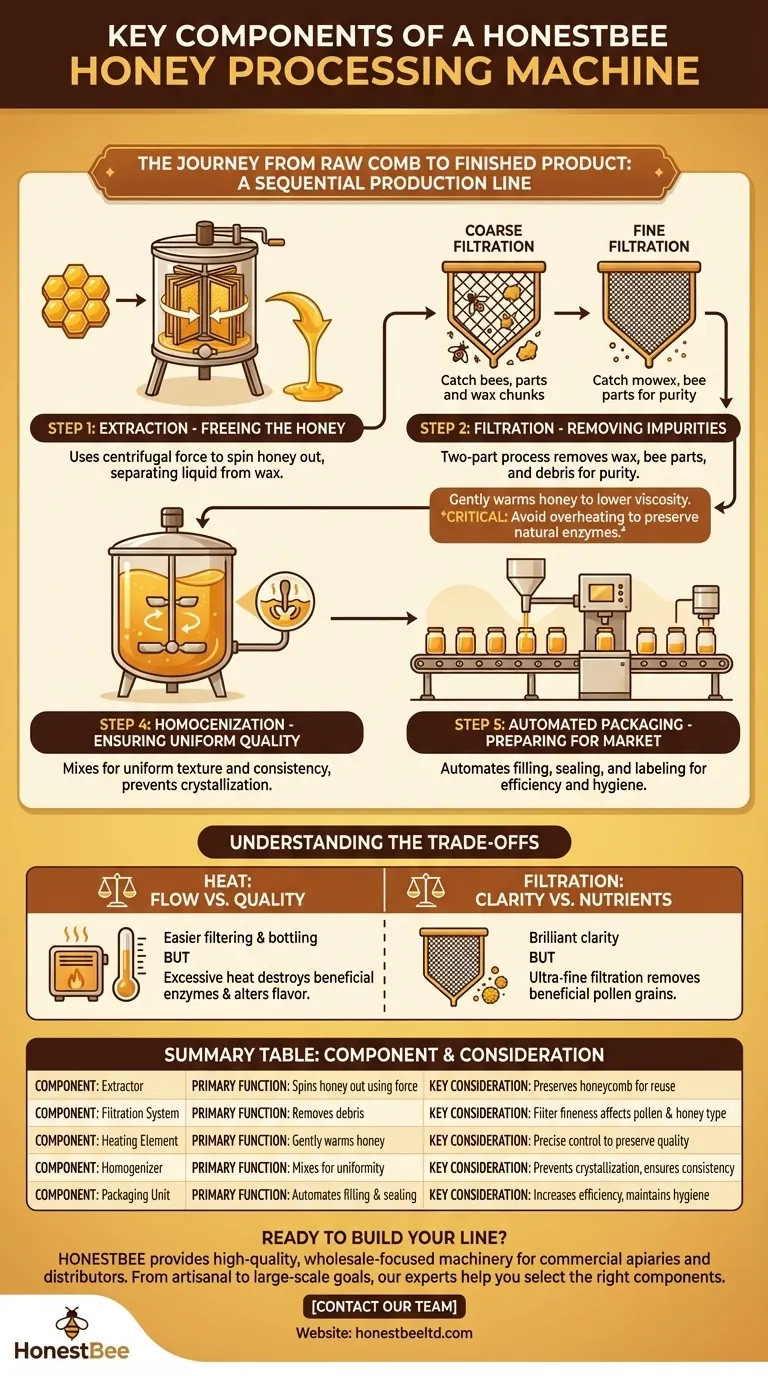

The Journey from Raw Honey to Finished Product

To truly understand the machine, we must follow the path honey takes through it. The process is a logical sequence of refinement, where each component prepares the honey for the next stage.

Step 1: Extraction - Freeing the Honey

The process begins with the honey extractor. This device uses centrifugal force to spin honey out of the honeycomb and wax cells without destroying the comb itself.

This initial step efficiently separates the liquid honey from its solid wax structure, collecting it for the subsequent purification stages.

Step 2: Filtration - Removing Impurities

Once extracted, the raw honey contains various particles like wax, bee parts, and other debris. The filtration system is responsible for removing them.

This is often a two-part process. Coarse filtration removes the larger particles first, followed by fine filtration to ensure a pure, clear final product.

Step 3: Heating - Improving Fluidity

To move efficiently through fine filters and bottling nozzles, honey often needs to be warmed. A gentle heating element or preheating tank is used to slightly lower the honey's viscosity.

The key is control. The goal is to improve flow without overheating the honey, which could destroy its natural enzymes and compromise its quality.

Step 4: Homogenization - Ensuring Uniform Quality

For large batches, a homogenizer or agitation tank ensures the final product is perfectly consistent. It gently mixes the honey to create a uniform texture and quality.

This step also helps melt any tiny crystallization nuclei, which can improve the honey's shelf life and appearance. Some systems use low-temperature concentration to achieve the desired standard.

Step 5: Automated Packaging - Preparing for Market

The final component is the automated packaging unit. This system fills jars or other containers with a precise volume of honey, preparing it for sealing, labeling, and distribution.

This automates a labor-intensive process, significantly increasing productivity and ensuring hygienic handling from the tank to the final container.

Understanding the Trade-offs

While these machines create efficiency and consistency, their operation involves critical decisions that directly impact the final product's quality.

The Double-Edged Sword of Heat

Heating makes honey easier to filter and bottle, and it can delay natural crystallization. However, excessive heat is the primary enemy of high-quality honey.

Overheating destroys beneficial enzymes and can alter the delicate flavor profile. The best systems use precise, low-temperature warming to preserve the honey's natural characteristics.

Filtration Level vs. Nutrient Retention

The degree of filtration is another crucial trade-off. Fine filtration creates brilliantly clear honey, which many consumers prefer.

However, ultra-fine filtration can remove beneficial pollen grains, which are a key feature of raw or artisanal honey. The choice of filter directly defines the type of honey you are producing.

Making the Right Choice for Your Goal

The ideal processing setup depends entirely on your operational scale and your philosophy on honey.

- If your primary focus is raw or artisanal honey: You need a system with minimal intervention, focusing on a quality extractor and coarse filtration while avoiding heat entirely.

- If your primary focus is large-scale commercial production: You need a fully integrated system with precise, controlled heating, fine filtration, and homogenization to guarantee product consistency and shelf stability.

- If your primary focus is efficiency for a small-to-medium operation: A modular approach is often best, starting with a high-quality extractor and filter and potentially adding gentle warming and bottling components as you grow.

Understanding these core components empowers you to control the final product, ensuring it perfectly aligns with your quality standards and business goals.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Extractor | Spins honey out of comb using centrifugal force | Preserves honeycomb for reuse |

| Filtration System | Removes wax, bee parts, and other debris | Filter fineness affects pollen content and honey type |

| Heating Element | Gently warms honey to improve flow for filtering/bottling | Precise temperature control is critical to preserve quality |

| Homogenizer | Mixes honey for uniform texture and consistency | Prevents crystallization and ensures batch uniformity |

| Packaging Unit | Automates filling and sealing of jars/bottles | Increases efficiency and maintains hygiene |

Ready to build or upgrade your honey processing line?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused machinery and components needed for success. Whether your goal is large-scale commercial consistency or artisanal quality control, our experts can help you select the right extractors, filters, and bottling systems to meet your specific production goals and quality standards.

Contact our team today for a consultation and discover how we can help you achieve a more efficient and profitable operation.

Visual Guide

Related Products

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What are the hardware and infrastructure requirements for HACCP in honey processing? Upgrade Your Facility for Export

- What is a honey processing plant? Scaling Your Honey Production with Advanced Commercial Machinery

- How does the determination of diastase activity (Gothe units) guide the optimization of honey processing equipment?

- What traditional beekeeping limitations are addressed by centralized honey processing equipment? Solve Quality & Scale

- How does the introduction of professional honey processing equipment address market constraints and quality issues?

- What role does deep-freezing equipment play in the honey FD pre-treatment? Ensure Perfect Sublimation and Structure

- What specific processing requirements existed for honey used in high-end food? Expert Standards for Premium Formulations

- Why is it necessary to strictly control environmental conditions during the cooling phase after boiling honey?