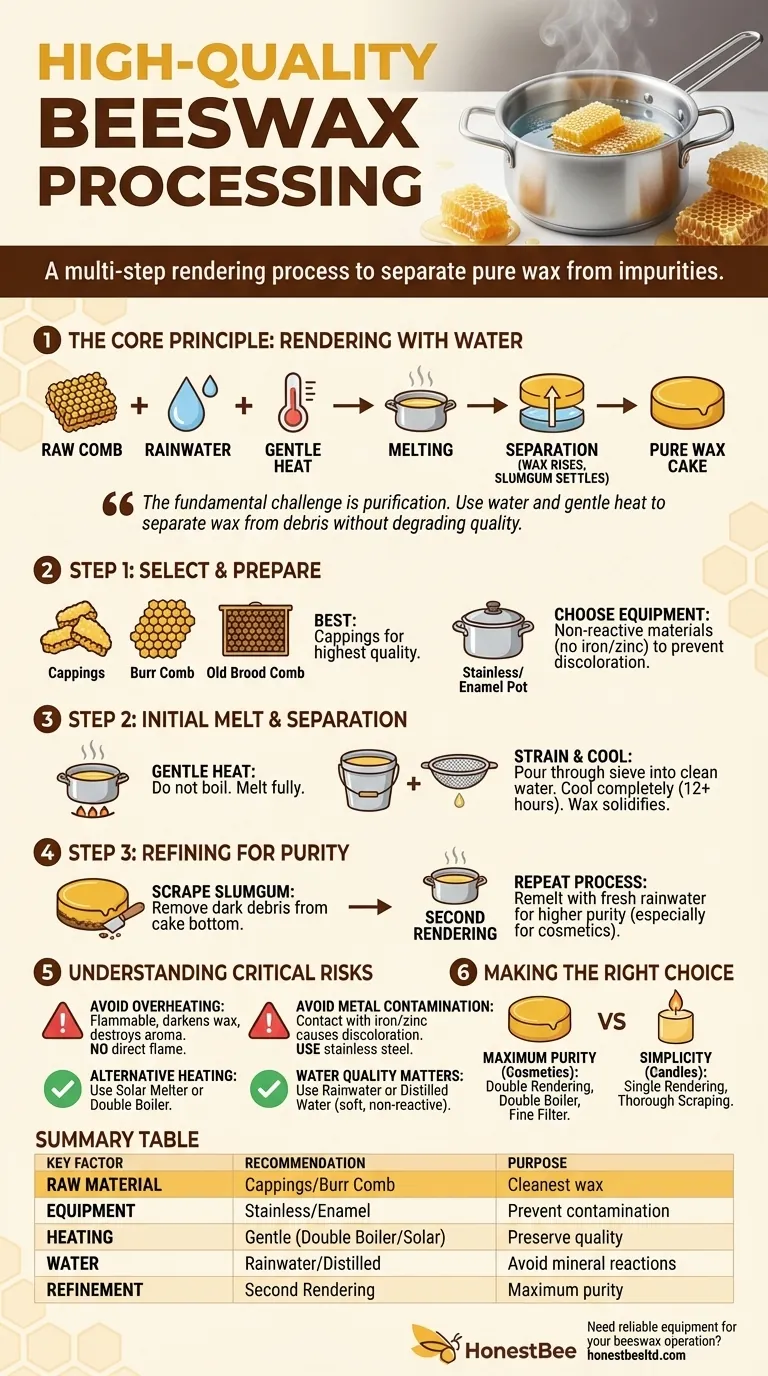

Processing raw beeswax is a multi-step rendering process designed to separate pure wax from impurities like honey, pollen, and propolis. The core method involves melting the raw comb in clean, soft water, allowing the mixture to cool and solidify, and then physically separating the pure wax cake from the debris-laden water and the "slumgum" that settles at the bottom.

The fundamental challenge in beeswax processing is not melting, but purification. The goal is to use water and gentle heat as tools to separate the lightweight, oil-based wax from heavier, water-soluble debris without degrading the wax's quality or color.

The Core Principle: Rendering with Water

Rendering is the process of melting down raw comb to purify the wax. Using water is critical because it serves two functions: it dissolves water-soluble impurities like honey and acts as a medium to allow solid debris to separate from the lighter, molten wax.

Selecting Your Raw Material

The quality of your starting material dictates the ease of processing. Wax can be collected from cappings removed during honey extraction, burr comb, or even old brood comb. Cappings generally yield the cleanest, highest-quality wax.

Choosing the Right Equipment

The container you use for melting is crucial. Pots should be made of stainless steel, aluminum, or enamel. These materials are non-reactive and will not discolor or contaminate the beeswax.

The Initial Melt and Separation

Place your raw comb into the pot. You can bundle it in a porous cloth or place it directly in the water. Add roughly twice as much clean rainwater as the volume of your wax.

Heat the mixture slowly until all the wax has melted. Do not boil it. Once fully melted, you can pour the mixture through a rough sieve into a clean bucket to remove the largest pieces of debris.

Allow the bucket to cool completely and undisturbed. This may take 12 hours or more. The pure wax, being lighter than water, will rise to the top and solidify into a single, hard cake.

Refining the Wax for Purity

A single rendering is often not enough for high-quality applications. Further refinement is necessary to produce a truly clean product.

Scraping the Debris

Once the wax cake is fully hardened, remove it from the water. The bottom surface of the cake will be coated in a dark, sludgy layer of fine debris known as slumgum. Scrape this layer off completely with a hive tool or sturdy knife.

The Importance of a Second Rendering

For a higher degree of purity, especially for cosmetics or lip balms, repeat the entire process. Break up your scraped wax cake, place it back in a clean pot with fresh rainwater, and gently melt it again.

This second rendering removes even more fine sediment, resulting in a cleaner, brighter, and more valuable final product.

Understanding the Trade-offs and Critical Risks

Achieving high-quality beeswax requires avoiding common pitfalls that can degrade or ruin your final product.

The Risk of Overheating

Beeswax is flammable and sensitive to high heat. Overheating can darken its color and destroy its delicate aroma. Never heat beeswax directly over a flame. A gentle, slow melt is essential for preserving its quality.

Alternative Heating Methods

To prevent overheating, consider using a solar wax melter, which uses the sun for a very gentle, slow melt. Alternatively, a double boiler provides excellent temperature control by using steam to indirectly heat the pot containing the wax and water.

The Problem with Metal Contamination

Contact with certain metals will permanently damage beeswax. You must avoid all contact with iron and zinc, as they will react with the wax and cause significant discoloration, turning it dark and muddy. This is why stainless steel is the preferred metal for all tools and containers.

Water Quality Matters

The recommendation to use rainwater is intentional. Tap water often contains minerals (i.e., it is "hard") that can react with the wax and affect the final quality. Rainwater or distilled water is soft and free from these reactive minerals.

Making the Right Choice for Your Goal

Your processing method should align with your intended use for the beeswax.

- If your primary focus is maximum purity for cosmetics: Perform a double rendering, use a double boiler for precise temperature control, and filter the final molten wax through a fine material like cheesecloth.

- If your primary focus is simplicity for candles or bulk blocks: A single, large-pot rendering may be sufficient, provided you are thorough when scraping the slumgum from the bottom of the wax cake.

By carefully managing heat and avoiding contamination, you can reliably transform raw comb into a clean, valuable, and versatile natural resource.

Summary Table:

| Key Factor | Recommendation | Purpose |

|---|---|---|

| Raw Material | Use cappings or burr comb | Yields the cleanest, highest-quality wax |

| Equipment | Stainless steel, aluminum, or enamel pots | Prevents metal contamination and discoloration |

| Heating Method | Gentle heat (double boiler or solar melter) | Prevents overheating and preserves wax quality |

| Water Type | Rainwater or distilled water | Avoids mineral reactions that degrade wax |

| Refinement | Perform a second rendering | Removes fine sediment for maximum purity |

Need reliable equipment for your beeswax operation? HONESTBEE supplies high-quality, commercial-grade beekeeping supplies and equipment to commercial apiaries and distributors. From stainless steel melting pots to solar wax melters, our wholesale-focused operations ensure you get the durable tools you need for efficient, high-yield processing. Contact us today to discuss your supply needs and elevate your beeswax quality!

Visual Guide

Related Products

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What are the key features of the electric double boiler for beeswax processing? Achieve Perfect, Safe Melting Every Time

- Why must the relative humidity inside the collector be monitored? 4 Key Reasons for Superior Beeswax Quality

- What are the key features of a direct heat melter? High-Intensity Thermal Solutions for Precision Melting

- Can you melt beeswax in an oven, and what are the risks? Expert Safety Guide for Proper Wax Handling

- What do you use a wax melter for? From Home Fragrance to Professional Beekeeping

- What is the function of the screen installed in a solar wax extractor? Maximize Wax Purity and Production Efficiency

- How does mechanized beeswax processing equipment contribute to resource recovery? Maximize Profit & Hive Efficiency

- What is the Solar Wax Melter and how does it operate? Reclaim Pure Beeswax with Free Solar Energy