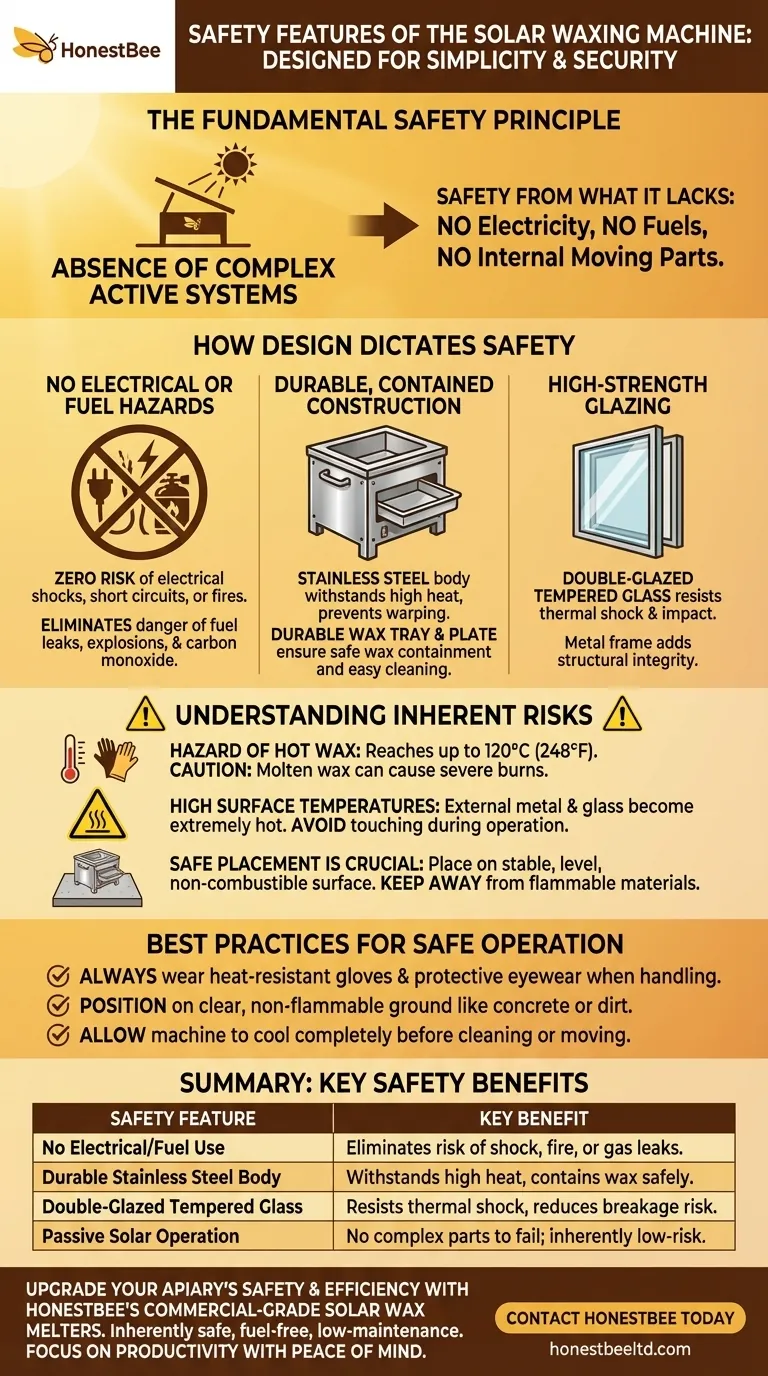

The fundamental safety of a solar waxing machine stems directly from its design simplicity. Its primary safety feature is the complete absence of electrical connections, heating elements, or combustible fuels like gas, which eliminates the most common sources of fire and electrocution risk found in other heating appliances.

A solar wax melter's safety is not based on complex active systems, but on what it lacks: it has no electricity to short-circuit, no fuel to leak, and no internal components to overheat and fail, making it an inherently low-risk device.

How Design Dictates Safety

The safety profile of a solar waxing machine is built into its core components and operational principles. It leverages passive solar energy within a robust, contained structure.

No Electrical or Fuel Hazards

The most significant safety advantage is its power source. By operating entirely on solar energy, it removes entire categories of risk.

There are no electrical connections, which means there is zero risk of short circuits, electrical shocks, or equipment fires caused by faulty wiring or power surges.

Similarly, the machine does not use gas or other fuels, eliminating the danger of leaks, explosions, or carbon monoxide emissions.

Durable, Contained Construction

The materials used are chosen for resilience under high-heat conditions, ensuring the hot wax remains safely contained.

The body is typically made of stainless steel, a material noted for its durability and resistance to high temperatures. This robust construction prevents warping or degradation, ensuring the unit remains structurally sound and "indestructible" over time.

Inside, a durable wax tray and a stainless steel plate for heat distribution are designed to withstand thermal stress and facilitate easy, safe cleaning.

High-Strength Glazing

The glass is a critical component for both efficiency and safety.

Solar melters use double-glazed, tempered glass. This design is highly resistant to thermal shock and physical impact, significantly reducing the risk of the glass shattering and spilling hot, molten wax. The metal frame enclosing the glass adds another layer of structural integrity.

Understanding the Inherent Risks

While the machine's design is inherently safe, the process of melting wax involves high temperatures, which requires operator awareness.

The Hazard of Hot Wax

The primary risk comes not from the device itself, but from its output. The melter is designed to reach temperatures up to 120°C (248°F) in direct sunlight.

Molten wax at this temperature can cause severe burns. It is critical to use appropriate personal protective equipment, such as heat-resistant gloves, when handling the internal tray.

High Surface Temperatures

The external surfaces of the machine, particularly the metal and glass, will become extremely hot during operation. Care must be taken to avoid touching the unit until it has had sufficient time to cool down.

Safe Placement is Crucial

While the machine does not use an open flame, the concentrated heat it generates still requires caution. It should always be placed on a stable, level, and non-combustible surface, well away from dry grass, leaves, or other flammable materials.

Best Practices for Safe Operation

To ensure a completely safe experience, your operational procedures are as important as the machine's design.

- If your primary focus is personal safety: Always wear heat-resistant gloves and protective eyewear when removing the wax collection tray.

- If your primary focus is fire prevention: Position the unit on a clear, non-flammable surface like concrete or dirt, far from any combustible materials.

- If your primary focus is equipment longevity: Allow the machine to cool completely before cleaning or moving it to prevent accidental burns or damage from thermal shock.

By understanding its simple design and respecting the heat it generates, you can operate a solar wax melter with exceptional confidence and safety.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| No Electrical/Fuel Use | Eliminates risk of shock, fire, or gas leaks. |

| Durable Stainless Steel Body | Withstands high heat, prevents warping, contains wax safely. |

| Double-Glazed Tempered Glass | Resists thermal shock and impact, reducing breakage risk. |

| Passive Solar Operation | No complex parts to fail; safety is built into the design. |

Upgrade your apiary's safety and efficiency with HONESTBEE's commercial-grade solar wax melters.

Designed for the demands of commercial beekeepers and distributors, our melters provide a inherently safe, fuel-free, and low-maintenance solution for processing wax. By eliminating electrical and fuel hazards, you can focus on productivity with complete peace of mind.

Ready to enhance your operation's safety profile? Contact HONESTBEE today to learn about our wholesale-focused offerings and durable equipment built for scale.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards