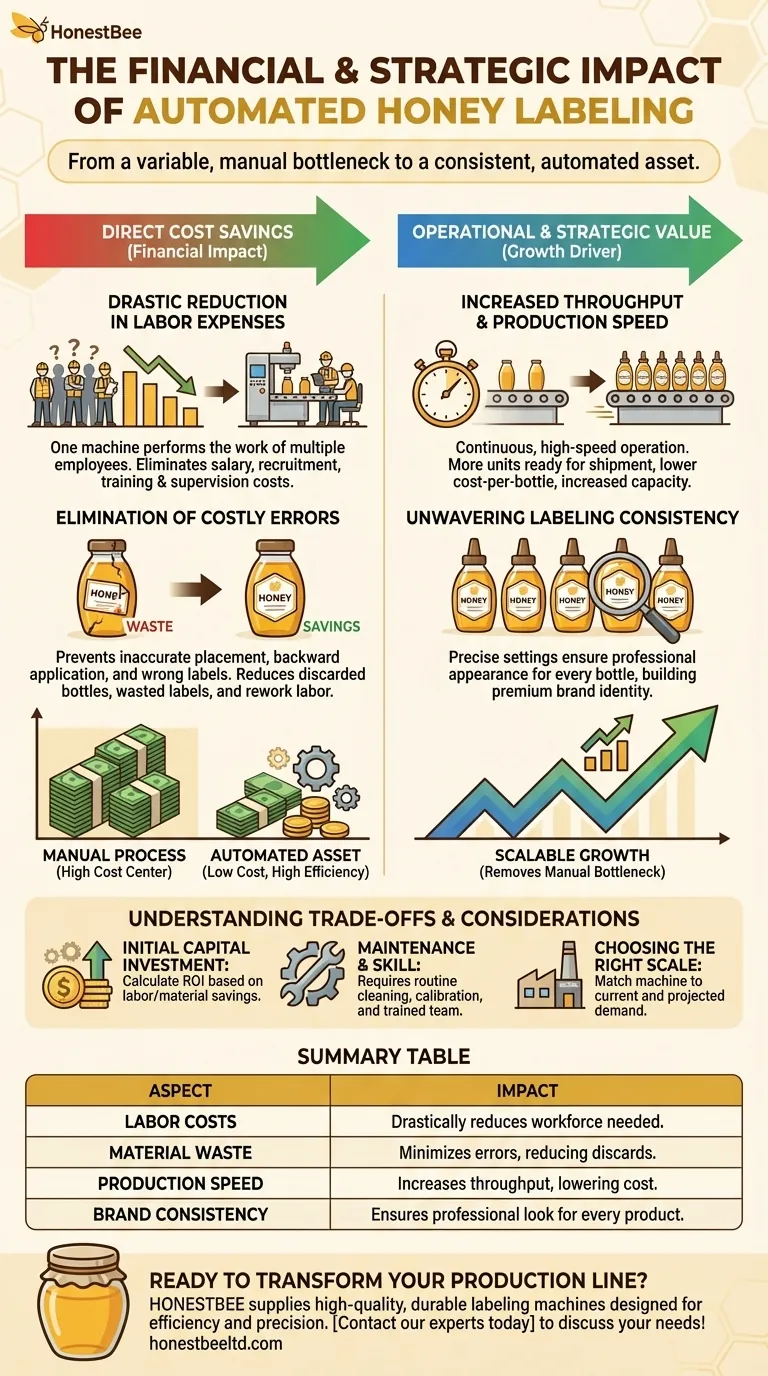

From a financial standpoint, a honey bottle labeling machine directly lowers production costs by automating a labor-intensive process and drastically reducing material waste from human error. This automation allows for a significant reduction in the workforce required for labeling, while the machine's precision ensures that each label is applied correctly, minimizing the costs associated with discarded products and rework.

The true impact of a labeling machine extends beyond simple cost-cutting. It represents a fundamental shift from a variable, manual bottleneck to a consistent, automated asset that enhances production efficiency, product quality, and long-term market competitiveness.

Analyzing the Direct Cost Savings

The most immediate and quantifiable impact of a honey bottle labeling machine is on your direct operational expenses. This is the primary driver for many producers considering the investment.

Drastic Reduction in Labor Expenses

Manual labeling requires a significant workforce, especially as production scales. A single automated machine can often perform the work of multiple employees.

This eliminates not only direct salary costs but also the associated expenses of recruitment, training, and ongoing supervision for a large labeling team.

Elimination of Costly Errors

Manual labeling is prone to human error, including inaccurate placement, backward application, or using the wrong label entirely.

Each of these errors results in a direct financial loss, whether through discarded bottles and honey, wasted labels, or the labor cost required for rework. Automation provides precise, repeatable accuracy that nearly eliminates this source of waste.

Beyond Costs: The Impact on Operational Efficiency

While cost savings are compelling, the machine's impact on your overall production flow provides a deeper, more strategic advantage.

Increased Throughput and Production Speed

An automated labeling machine works continuously and at a much higher speed than any manual process.

This increases your overall production throughput, meaning more units can be labeled and made ready for shipment in less time. This directly lowers the cost-per-bottle and increases your capacity to meet larger orders.

Unwavering Labeling Consistency

Advanced labeling machines use precise settings to control the exact placement and fit of every label.

This ensures that every bottle that leaves your facility has the same professional appearance. This level of consistency is impossible to achieve with manual labor and is critical for building a premium brand identity.

Understanding the Trade-offs and Considerations

As with any capital investment, a labeling machine is not a universal solution. An objective analysis requires understanding the potential downsides.

The Initial Capital Investment

The most significant barrier is the upfront purchase price of the machine. This requires a careful calculation of your return on investment (ROI) based on projected labor and material savings.

Maintenance and Operational Skill

These machines are not "plug-and-play." They require routine cleaning, maintenance, and calibration to perform optimally.

Your team will also need training to operate the machine efficiently, handle changeovers for different bottle sizes, and troubleshoot minor issues.

Choosing the Right Scale

A machine designed for a massive factory will be an inefficient and overly expensive choice for a small-batch apiary. Conversely, a small machine will become a bottleneck for a rapidly growing operation. Selecting a machine that matches your current and near-future scale is critical.

The Strategic Value: Enhancing Market Competitiveness

The long-term benefits of automated labeling are about positioning your business for growth and strengthening your brand in a crowded market.

Improved Product Aesthetics and Brand Perception

A perfectly applied label signals quality and professionalism to the consumer before they even open the bottle. This enhanced shelf appeal can directly influence purchasing decisions and support a premium price point.

Enabling Scalable Growth

A manual labeling process is a common bottleneck that prevents a business from scaling effectively. An automated labeling machine removes this barrier, allowing you to increase production capacity without a proportional increase in labor costs.

Making the Right Choice for Your Operation

The decision to invest in a honey bottle labeling machine should be aligned with your specific business goals.

- If your primary focus is immediate cost reduction: Calculate your payback period by comparing the machine's total cost against your annual savings on labor and wasted materials.

- If your primary focus is scaling production: Prioritize a machine's throughput (bottles per minute) to ensure it can handle your projected future demand.

- If your primary focus is brand quality: Focus on machines known for their precision and consistency to ensure a premium look for every product.

Ultimately, investing in a labeling machine is a strategic decision that transforms a manual cost center into a driver of efficiency, quality, and growth.

Summary Table:

| Aspect | Impact |

|---|---|

| Labor Costs | Drastically reduces workforce needed for manual labeling. |

| Material Waste | Minimizes errors, reducing discarded bottles and labels. |

| Production Speed | Increases throughput, lowering the cost per bottle. |

| Brand Consistency | Ensures a professional look for every product. |

Ready to transform your honey production line and boost your profitability? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable labeling machines designed for efficiency and precision. Our wholesale-focused operations ensure you get the right equipment to scale your business, reduce costs, and enhance your brand. Contact our experts today to discuss your specific needs and receive a personalized quote!

Visual Guide

Related Products

- Automatic In-Line Round Bottle Labeling Machine

- Automatic Dual Sided In Line Labeling Machine

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- 10L Stainless Steel Electric Honey Press Machine

- Automatic Honey Frame Uncapper Machine for Beekeeping

People Also Ask

- What role do specialized packaging materials play in stingless bee by-products? Preserve Bioactive Potency and Value

- Why is it essential to integrate a high-performance automatic labeling system? Secure Trust and Compliance in Honey

- How does a honey bottle labeling machine help reduce human errors? Ensure Flawless Branding and Precision

- Why are botanical source and harvest year labels essential? Unlock Premium Honey Value and Traceability

- Why is commercial-grade honey packaging equipment essential? Ensure Product Stability in Long-Distance Logistics

- How can one troubleshoot wrinkled or torn packaging film during operation? Expert Fixes for Smooth Packaging Lines

- How do professional packaging designs and labeling materials affect the marketing of honey products? Boost brand value!

- How does the implementation of Industrial Packaging and Certification Equipment affect the market positioning of honey?