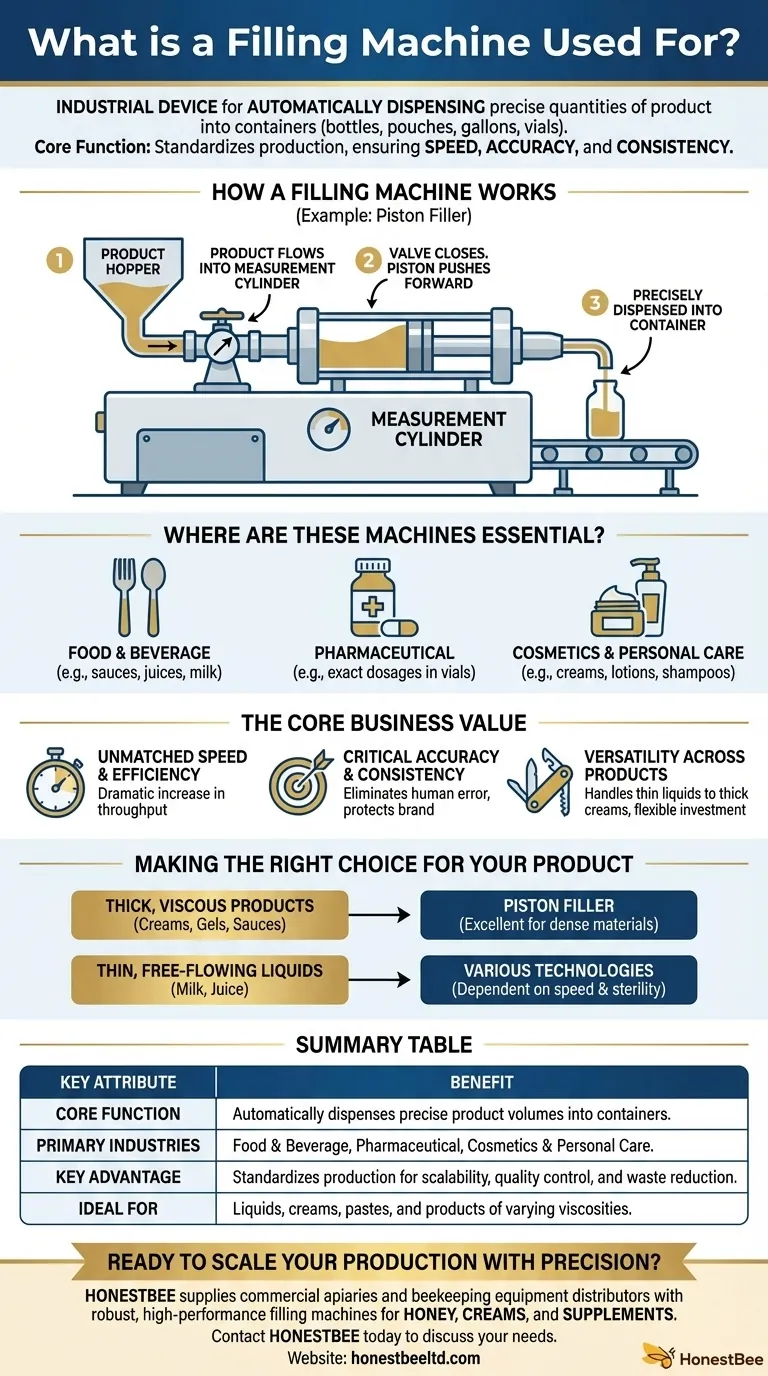

At its core, a filling machine is an industrial device used to automatically dispense a specific quantity of a product into containers like bottles, pouches, gallons, or vials. These machines are a cornerstone of modern production, replacing manual labor to ensure speed, accuracy, and consistency across thousands of units.

The true purpose of a filling machine isn't just to fill containers; it's to standardize the production process. This automation is critical for companies to scale operations, maintain product quality, and minimize waste.

How a Filling Machine Works

Understanding the mechanics of a filling machine reveals why it is so essential for modern industry. While many types exist, the principle of controlled, repeatable dispensing is universal.

The Basic Principle: Dispensing a Precise Volume

The fundamental job of any filling machine is to take a bulk product—be it a liquid, cream, or paste—and portion it out into exact, predetermined volumes for packaging.

A Common Example: The Piston Filler

A piston filler provides a clear illustration of this process. A valve opens, allowing the product to flow from a large tank, or hopper, into a measurement cylinder.

Once the cylinder is full, the valve to the hopper closes. A piston then pushes forward, forcing the precisely measured product out through a nozzle and into the waiting container. This mechanism is highly versatile and reliable.

Where Are These Machines Essential?

Filling machines are indispensable across numerous industries where product consistency and production speed are paramount.

Food and Beverage

From milk factories to companies producing sauces and juices, filling machines handle products of varying thicknesses (viscosities). They ensure that every bottle of juice or jar of pasta sauce contains the exact same amount of product.

Pharmaceutical Companies

In pharmaceuticals, precision is a matter of safety, not just quality. Filling machines are used to dispense exact dosages into vials and bottles, a task that requires an extremely high degree of accuracy and a sterile environment.

Cosmetics and Personal Care

Products like creams, lotions, and shampoos often have a thick consistency. Piston fillers and similar systems are particularly effective at handling these viscous materials, ensuring each container is filled cleanly and accurately.

The Core Business Value

Investing in a filling machine is a strategic decision driven by significant operational advantages. It addresses core challenges in scaling a business.

Unmatched Speed and Efficiency

An automated filling machine can process hundreds or thousands of containers in the time it would take to fill a handful manually. This dramatic increase in throughput is essential for meeting market demand.

Critical Accuracy and Consistency

Manual filling is prone to human error, leading to under-filled or over-filled containers. This results in wasted product and inconsistent customer experience. A machine repeats its task perfectly every time, protecting brand reputation and the bottom line.

Versatility Across Products

Many filling systems, like the piston filler, are designed to handle a wide range of product types. They can be adjusted to work with thin liquids, thick creams, and even products containing small solid particles, making them a flexible long-term investment.

Making the Right Choice for Your Product

The key to selecting the right filling technology is understanding the physical properties of your product.

- If your primary focus is on thick, viscous products like creams, gels, or sauces: A piston filler is an excellent and reliable choice due to its ability to forcefully and accurately dispense dense materials.

- If your primary focus is on thin, free-flowing liquids like milk or juice: The choice of machine will be heavily dependent on your required speed and the need for a sterile environment, as different technologies are optimized for these factors.

Ultimately, integrating the right filling machine transforms a production line from a manual process into a high-speed, reliable, and scalable operation.

Summary Table:

| Key Attribute | Benefit |

|---|---|

| Core Function | Automatically dispenses precise product volumes into containers. |

| Primary Industries | Food & Beverage, Pharmaceutical, Cosmetics & Personal Care. |

| Key Advantage | Standardizes production for scalability, quality control, and waste reduction. |

| Ideal For | Liquids, creams, pastes, and products of varying viscosities. |

Ready to scale your production with precision?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, high-performance filling machines needed to handle products like honey, creams, and supplements. Our wholesale-focused operations ensure you get the right equipment to boost your efficiency and accuracy.

Contact HONESTBEE today to discuss your filling needs and discover the perfect solution for your business.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- Lightweight Plastic Uncapping Roller with Tines

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What is the significance of specialized honey filling equipment? Scaling from Beekeeping to Commercial Success

- What is a Multi Lane Honey Sachet Packing Machine and when is it used? Maximize Your High-Volume Honey Production

- What advantages do automated honey-filling machines provide? Scale Your Honey Production with Precision and Hygiene

- How do high-precision filtration and filling equipment contribute to honey competitiveness? Elevate Your Product Standards

- Why is the use of industrial-grade automatic filling machines significant for Eucalyptus honey? Ensure Quality & Purity

- What is the role of Automated Honey-filling Machines? Scale Your Honey Brand with Precision and Safety

- What technical challenges do industrial honey-filling machines address? Solving Efficiency and Hygiene in Production

- How do high-precision honey-filling machines maintain product quality? Safeguard Purity and Consistency