At its core, the capping and sealing process is the final, critical step in a filling machine's operation, designed to guarantee product integrity. This process serves two primary functions: it physically contains the product by preventing leaks and it protects the product's quality by creating a barrier against external contaminants.

Capping and sealing are not merely about closing a container. They are a strategic engineering decision that directly impacts product safety, shelf life, and brand reputation, acting as the ultimate gatekeeper between your product and the outside world.

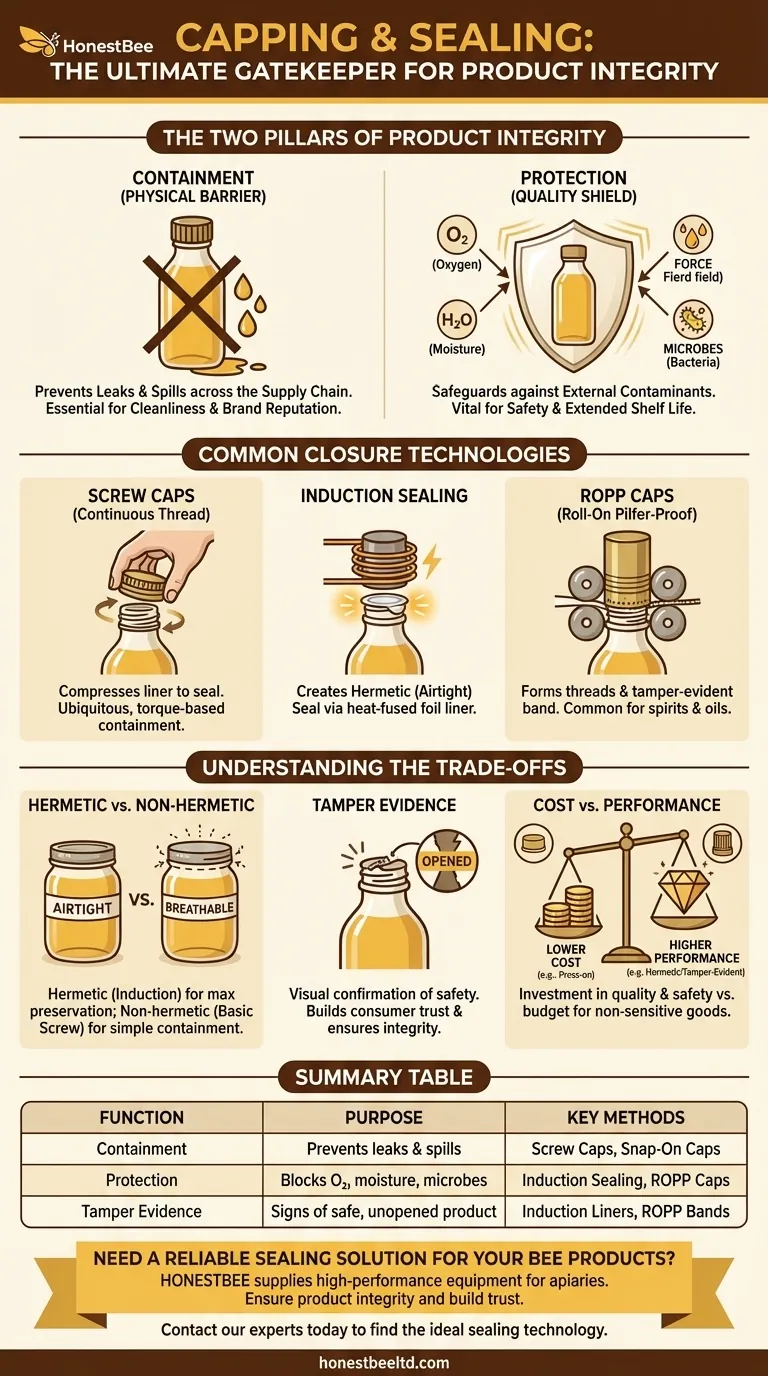

The Two Pillars of Product Integrity

The purpose of any closure system can be broken down into two fundamental responsibilities: containment and protection. While related, they address different risks in the product's lifecycle.

Containment: The Physical Barrier

The most obvious function of a cap is containment. It creates a physical barrier to stop the product from spilling or leaking out of its container.

This is essential not just for the end consumer, but throughout the entire supply chain. A failed seal leads to lost product, damaged secondary packaging, and costly cleanups during shipping and storage. On a retail shelf, a leaky container is unsellable and reflects poorly on the brand.

Protection: The Quality Shield

Beyond simple containment, the seal acts as a protective shield for the product inside. It safeguards the contents from a range of external factors that can degrade quality and shorten shelf life.

This includes preventing the ingress of oxygen, moisture, microorganisms, and other environmental contaminants. For many food, beverage, and pharmaceutical products, this protection is non-negotiable for ensuring safety and efficacy.

Exploring Common Closure Technologies

The method used for capping and sealing depends entirely on the product, the container type, and the required level of protection.

Screw Caps (Continuous Thread)

This is the most ubiquitous closure type, found on everything from water bottles to jars of sauce. The cap is tightened to a specific torque value, compressing a liner inside the cap against the rim of the container to form a seal.

Induction Sealing

For a truly airtight, or hermetic seal, induction sealing is the industry standard. A multi-layer liner is placed inside the cap, with one layer being aluminum foil. After capping, the container passes through an electromagnetic field, which heats the foil and melts a polymer layer, fusing it to the container's rim.

ROPP Caps (Roll-On Pilfer-Proof)

Commonly used for wine and spirits, ROPP caps are unthreaded aluminum shells. The capping machine presses the cap onto the bottle and uses rollers to form the threads directly onto the bottle's neck. This process simultaneously creates a tight seal and a perforated, tamper-evident band at the base.

Understanding the Trade-offs

Choosing the right closure system involves balancing protection, cost, and consumer experience. There is no single "best" method; there is only the best method for a specific application.

Hermetic vs. Non-Hermetic Seals

The most critical distinction is between a hermetic seal and a non-hermetic one. An induction seal is hermetic—it is impermeable to air and gas exchange, which is vital for preserving freshness in products like coffee or cooking oil. A basic screw cap without an induction liner is non-hermetic; it provides good containment but offers minimal protection against oxygen or moisture ingress over time.

Tamper Evidence as a Critical Feature

Many sealing methods are designed to provide clear tamper evidence. ROPP caps and induction seals must be broken to open the container, giving consumers a clear, visual confirmation that the product has not been opened since it left the factory. This is a crucial feature for building consumer trust and ensuring safety.

Cost vs. Required Performance

A simple press-on cap is far less expensive than a multi-part induction-ready screw cap. The decision comes down to a risk-benefit analysis. For non-sensitive industrial products, a basic cap may be sufficient. For high-value pharmaceuticals or oxygen-sensitive foods, the added cost of a hermetic, tamper-evident seal is a necessary investment in product quality and safety.

Matching the Method to Your Product's Needs

Your choice of capping and sealing technology should be driven by the specific demands of your product and market.

- If your primary focus is maximum shelf life and safety (foods, beverages, pharma): An induction seal is the definitive choice for creating a hermetic, tamper-evident barrier.

- If your primary focus is cost-effective containment for non-sensitive goods (dry goods, some chemicals): A standard continuous thread screw cap or snap-on cap offers reliable performance.

- If your primary focus is tamper evidence and a premium feel (spirits, high-value oils): A ROPP capping system provides an excellent seal while clearly demonstrating product integrity.

Ultimately, the right closure strategy transforms a simple package into a secure, reliable, and trustworthy product.

Summary Table:

| Function | Purpose | Key Methods |

|---|---|---|

| Containment | Prevents leaks and spills during shipping and storage. | Screw Caps, Snap-On Caps |

| Protection | Blocks oxygen, moisture, and microbes to preserve quality. | Induction Sealing, ROPP Caps |

| Tamper Evidence | Provides a clear sign the product is safe and unopened. | Induction Liners, ROPP Bands |

Need a reliable sealing solution for your products?

HONESTBEE supplies high-performance capping and sealing equipment to commercial apiaries and beekeeping equipment distributors. We understand that protecting the quality of your honey, propolis, and other bee products is non-negotiable. Our solutions help you achieve the perfect seal to ensure product integrity, extend shelf life, and build consumer trust.

Contact our experts today to find the ideal sealing technology for your operation.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic Honey Frame Uncapper Machine for Beekeeping

- HONESTBEE 24 Head Rotary Bottle Washing Machine

- Lightweight Plastic Uncapping Roller with Tines

- Professional Stainless Steel Uncapping Fork with Wooden Handle

People Also Ask

- What are the benefits of using automated honey filling machines? Boost Efficiency and Preserve Quality

- Are honey-filling machines built with durable materials? Discover Why 304 Stainless Steel is the Industry Standard

- What technical benefits do automated honey filling machines provide? Optimize Your Large-Scale Honey Packaging Today

- What is the working principle of a honey stick packing machine? Automate Your Honey Production Line

- What are the different principles used in honey filling machines? Choose the Right Method for Your Apiary

- What are the primary benefits and features of a honey filling machine? Boost Efficiency with Automated Precision

- Why is precision and consistency a crucial feature in a honey packaging machine? Maximize Profits and Quality

- What is the function of the motor in a honey stick machine? Powering Your Honey Stick Production