The defining feature of a new generation honey filling machine is its advanced electronic control unit. This central component moves beyond simple mechanical operation, acting as a digital brain that enables a more efficient, precise, and flexible workflow through a wide array of new programmable settings.

While traditional machines successfully perform the basic task of filling jars, the new electronic control unit is a transformative upgrade. It is not just another feature, but a central nervous system that enhances every core function of the machine—improving precision, speed, and overall adaptability.

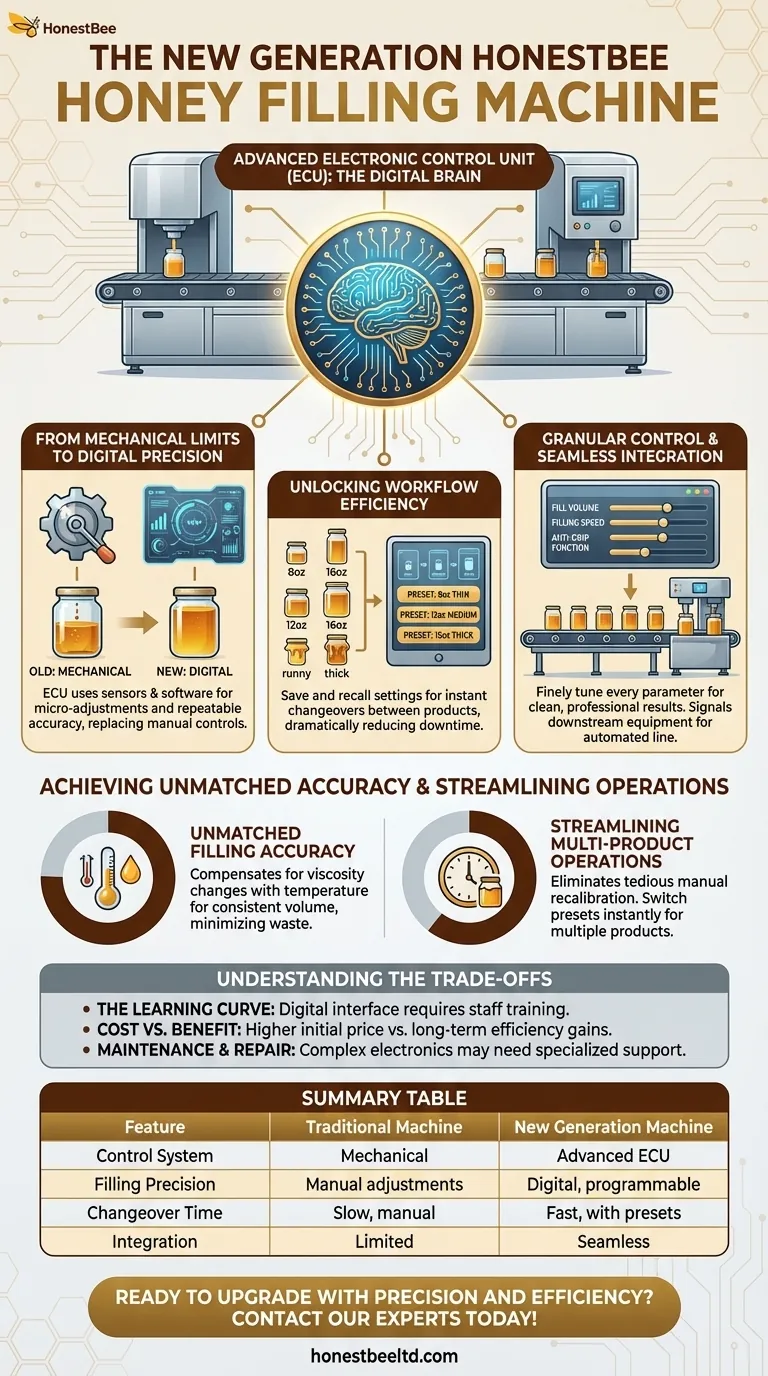

The Role of the Electronic Control Unit (ECU): The New "Brain"

The introduction of a sophisticated ECU marks the primary distinction between modern machines and their predecessors. This unit governs the entire operation, replacing rigid mechanical controls with dynamic digital management.

From Mechanical Limits to Digital Precision

Older machines often rely on manual adjustments and mechanical stops to control volume. The new ECU digitizes this process, using sensors and software for control.

This allows for micro-adjustments and a level of repeatability that is difficult to achieve with purely mechanical systems.

Unlocking Workflow Efficiency

The ECU allows operators to save and recall specific settings for different products. This feature, mentioned in the references as "many different optional settings," is critical for producers handling various jar sizes or honey viscosities.

Changeover between production runs becomes a matter of selecting a preset program, dramatically reducing downtime.

Granular Control Over Filling Parameters

The "brain" of the ECU provides direct command over the machine's "muscles," such as the volumetric or piston filling systems.

Operators can finely tune not just the fill volume, but also the filling speed and anti-drip functions, ensuring a clean and professional result for every single jar.

How This Enhancement Improves Core Functions

The ECU is not an isolated component; its value is measured by how it improves the fundamental tasks of honey production. It elevates the machine from a simple dispenser to an intelligent packaging tool.

Achieving Unmatched Filling Accuracy

Honey's viscosity can change with temperature, which can affect fill volume. An advanced ECU can be programmed to compensate for these variables, ensuring consistent volume and minimizing product waste.

This directly addresses the core function of precise filling, but with a much higher degree of reliability.

Streamlining Multi-Product Operations

For a business that sells honey in 8oz, 12oz, and 16oz jars, the ECU is a game-changer. It eliminates the tedious manual recalibration required by older machines.

An operator can simply switch to the "16oz Jar" setting, and the machine instantly adjusts its parameters for the correct volume and speed.

Integrating with the Entire Production Line

Modern ECUs are designed for connectivity. They can signal downstream equipment, such as automatic capping and sealing mechanisms, to create a seamless and automated production line from filling to final sealing.

Understanding the Trade-offs

While advanced, this new technology is not without its considerations. A clear understanding of the trade-offs is essential for making an informed investment.

The Learning Curve

A machine with an advanced ECU has a digital interface, not just a few knobs and levers. Staff will require training to effectively use the new settings and programming features.

Cost vs. Benefit Analysis

The inclusion of sophisticated electronics and software increases the initial purchase price of the machine. The return on this investment must be calculated based on gains in efficiency, reduced product waste, and labor savings.

Maintenance and Repair

While highly reliable, electronic components can be more complex to diagnose and repair than simple mechanical parts. It is important to consider the manufacturer's technical support and service options.

Making the Right Choice for Your Operation

The decision to invest in a new generation machine depends entirely on your specific production goals and scale.

- If your primary focus is small-batch, single-product production: A simpler machine may be sufficient, but a new-generation model offers superior consistency and future-proofing for growth.

- If your primary focus is efficiency with multiple products: The ECU's ability to save presets and speed up changeovers provides a significant return on investment and is a critical advantage.

- If your primary focus is premium branding and quality control: The unmatched precision of an electronically controlled system is non-negotiable for ensuring every jar meets your high standards.

Ultimately, understanding this technology empowers you to select a machine that is a strategic investment in your operational efficiency and product quality.

Summary Table:

| Feature | Traditional Machine | New Generation Machine |

|---|---|---|

| Control System | Mechanical | Advanced Electronic Control Unit (ECU) |

| Filling Precision | Manual adjustments | Digital, programmable micro-adjustments |

| Changeover Time | Slow, manual recalibration | Fast, with saved presets |

| Integration | Limited | Seamless with capping/sealing equipment |

Ready to upgrade your honey production with precision and efficiency?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides the advanced honey filling equipment you need to scale your operations, reduce waste, and ensure consistent, high-quality results. Our machines are built for the demands of modern beekeeping businesses.

Contact our experts today to find the perfect filling solution for your apiary!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What are the main types of volumetric filling machines? Find the Right Filler for Your Product

- Are honey-filling machines available in both semi-automatic and automatic types? Choose the Right Fit for Your Apiary

- What are the advantages of using industrial-grade high-precision honey filling machines for unifloral honey packaging?

- In what ways do automatic honey-filling machines facilitate professional production? Scale Your Apiary Efficiently

- How do industrial-grade honey filling machines contribute to organic honey production? Scaling with Purity

- What is a piston filling machine and how does it work? Achieve Precise Filling for Viscous Products

- What role do automatic honey-filling machines play? Enhancing Honey Purity and Commercial Sustainability

- What other liquids can the honey filling machine bottle? Versatile Viscous Liquid Packaging Solutions