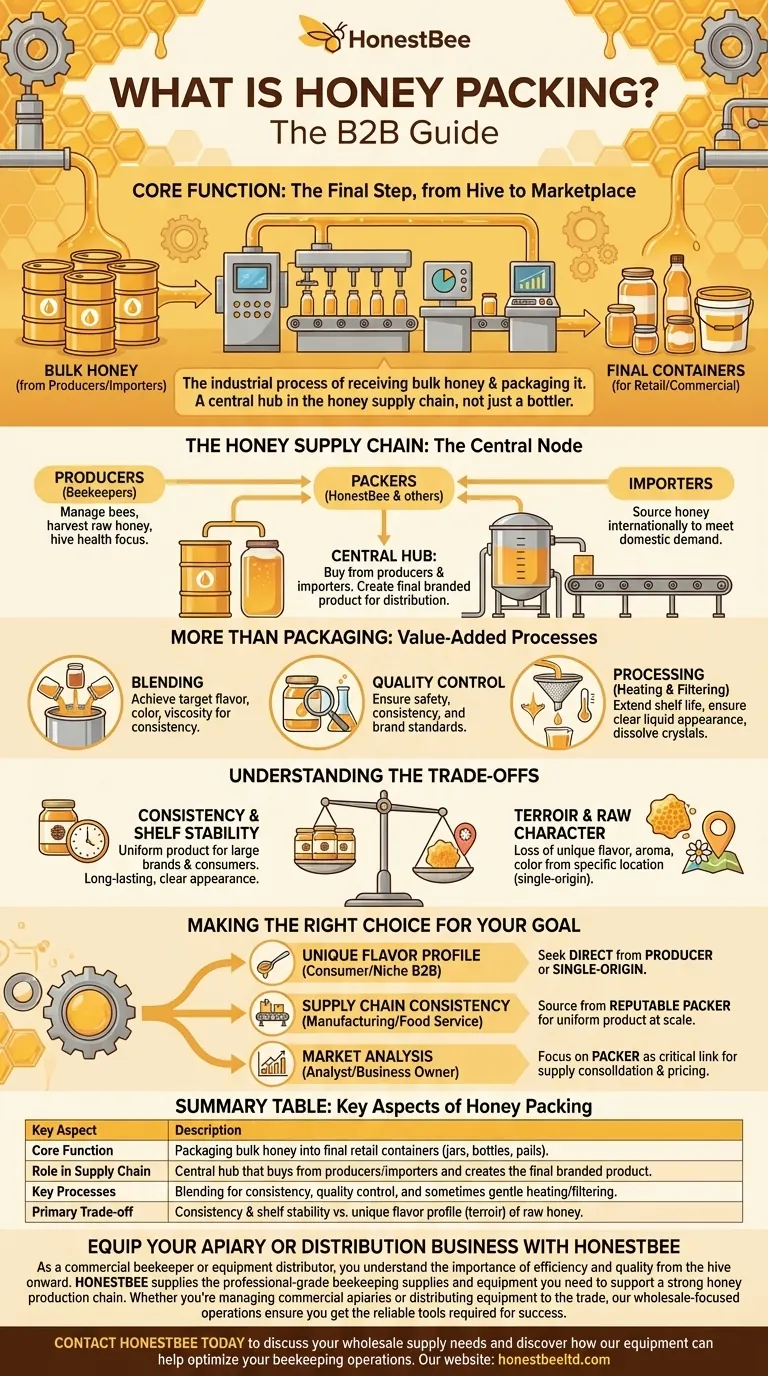

At its core, honey packing is the final, critical step in bringing honey from the hive to the marketplace. It is the industrial process of receiving bulk honey and packaging it into the final containers—such as jars, bottles, or food service pails—that will be sold to either retail consumers or commercial businesses.

A honey packer is more than just a bottler; they are a central hub in the honey supply chain. They often perform crucial functions like blending, quality control, and processing that define the consistency and character of the honey you find on the shelf.

The Role of the Honey Packer in the Supply Chain

The honey industry is often segmented into three distinct but interconnected groups: producers, importers, and packers. Understanding the packer's function is key to understanding the entire market.

From Bulk to Bottle

The most fundamental role of a honey packer is logistical. They receive honey in large quantities, typically in 55-gallon drums or larger totes, from beekeepers (producers) or importers.

Their facility is equipped with the machinery to transfer, and sometimes process, this bulk honey into consumer-friendly packaging.

The Three Pillars of the Industry

To grasp the packer's significance, it helps to see where they fit.

- Producers (Beekeepers): They manage the bees and harvest the raw honey from the hives. Their focus is on hive health and honey production.

- Importers: They source honey from various countries to meet domestic demand that local production cannot satisfy.

- Packers: They are the central node. Packers buy honey from both domestic producers and international importers, creating the final branded product that is distributed to stores.

More Than Just Packaging

The term "packer" can understate their full role. Large-scale packers are often responsible for creating a specific, consistent product that consumers recognize.

This frequently involves blending honey from different floral sources, regions, or even countries to achieve a target flavor, color, and viscosity. It also ensures the product on the shelf in New York tastes the same as the one in California.

Understanding the Trade-offs

The packer's processes have a significant impact on the final product, leading to important trade-offs between consistency and character.

Consistency vs. Terroir

By blending honey, packers create a reliable, uniform product. This is essential for large food brands and for consumers who expect their favorite honey to taste the same every time.

The trade-off is the loss of terroir—the unique flavor, aroma, and color profile that comes from a specific location and floral source. Single-origin honey reflects a time and place, while blended honey reflects a brand standard.

Processing and Shelf Stability

To ensure a long shelf life and the clear, liquid appearance many consumers prefer, packers may gently heat and filter the honey. Heating helps dissolve sugar crystals and filtering removes pollen and wax particles.

However, this processing can be a point of contention. Over-heating can diminish the subtle flavors and beneficial enzymes found in raw honey. This is why a distinction is often made between a large commercial packer's product and "raw and unfiltered" honey sold directly by a beekeeper.

Making the Right Choice for Your Goal

Understanding the packer's role allows you to make more informed decisions, whether as a consumer, a business owner, or an analyst.

- If your primary focus is a unique flavor profile: Seek out honey sold directly by the producer (beekeeper) or labeled as "single-origin" to experience its natural terroir.

- If your primary focus is supply chain consistency: Sourcing from a reputable packer is the most effective way to guarantee a uniform product at scale for manufacturing or food service.

- If your primary focus is market analysis: The packer is the critical link where supply from producers and importers is consolidated, priced, and transformed into a branded consumer good.

Recognizing the function of the honey packer empowers you to navigate the market with greater precision and insight.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Packaging bulk honey into final retail containers (jars, bottles, pails). |

| Role in Supply Chain | Central hub that buys from producers/importers and creates the final branded product. |

| Key Processes | Blending for consistency, quality control, and sometimes gentle heating/filtering. |

| Primary Trade-off | Consistency & shelf stability vs. unique flavor profile (terroir) of raw honey. |

Equip Your Apiary or Distribution Business with HONESTBEE

As a commercial beekeeper or equipment distributor, you understand the importance of efficiency and quality from the hive onward. HONESTBEE supplies the professional-grade beekeeping supplies and equipment you need to support a strong honey production chain.

Whether you're managing commercial apiaries or distributing equipment to the trade, our wholesale-focused operations ensure you get the reliable tools required for success.

Contact HONESTBEE today to discuss your wholesale supply needs and discover how our equipment can help optimize your beekeeping operations.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What role do honey filling machines play in meeting quality standards? Ensure Global Export Compliance

- Why is a specialized honey filling machine necessary? Meet International Standards and Preserve Premium Honey Quality

- What role do automated honey-filling machines play in trade standards? Ensure Global Export Compliance & Consistency

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- What is the primary function of industrial filling equipment? Maximize Honey Profitability and Market Access