At its core, the Auto Flow Beehive design is an evolution of the globally recognized Langstroth hive. It uses the same modular, box-based structure but revolutionizes the honey harvesting process by integrating patented frames. These special frames allow honey to be drained directly from the hive without opening it, fundamentally changing the interaction between the beekeeper and the bees.

The central design principle is to separate the act of honey harvesting from the act of hive intrusion. By creating a mechanical system to release honey on-demand, the Auto Flow design aims to eliminate the stress on the bee colony and the complex labor traditionally required to extract honey.

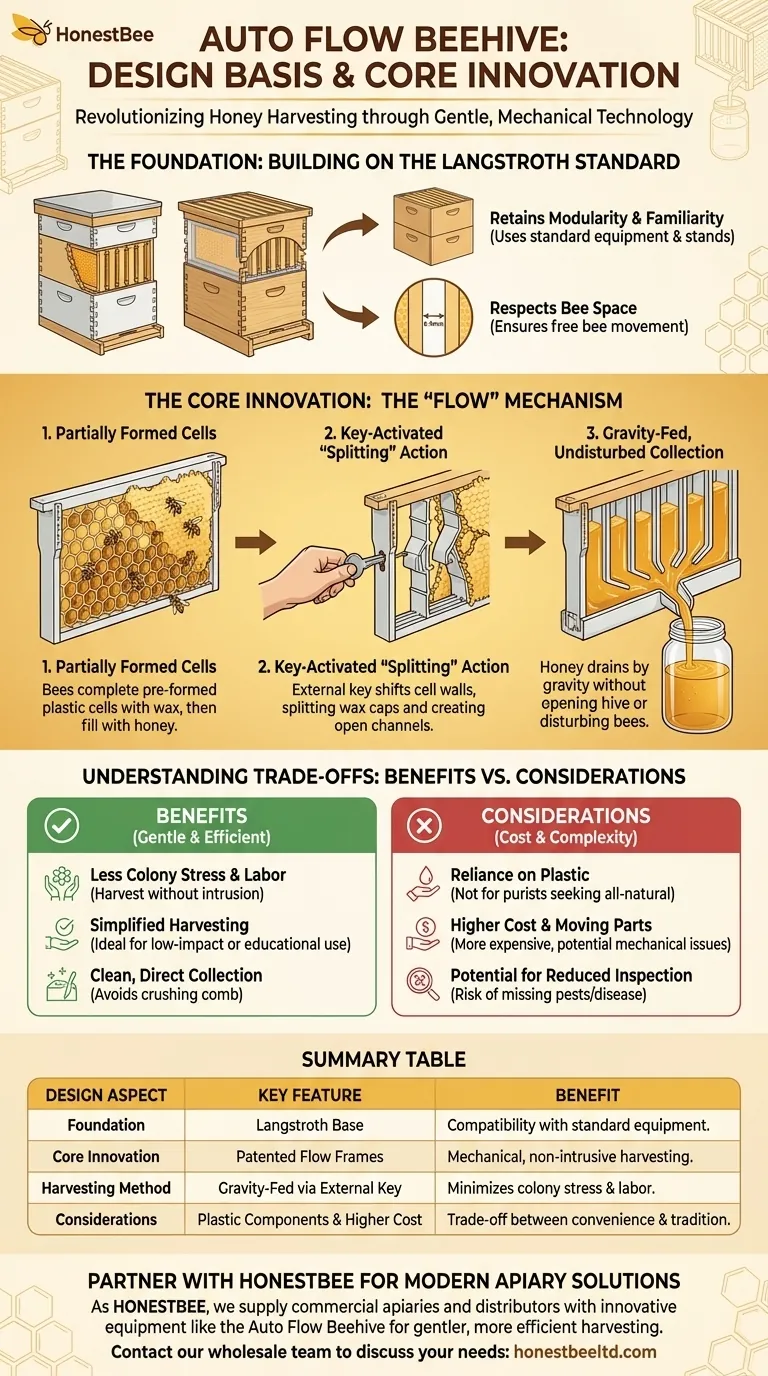

The Foundation: Building on the Langstroth Standard

The decision to base the Auto Flow hive on the Langstroth system was a strategic one, designed to integrate a new technology into an established beekeeping practice.

Retaining Modularity and Familiarity

The Langstroth hive, invented in the 1850s, is the world's most common beehive. It consists of vertically stackable boxes ("supers") containing frames that hold the honeycomb.

By adopting this same footprint, the Auto Flow hive ensures that beekeepers can use existing stands, roofs, and other standard equipment. This makes adoption easier and less disruptive for those already familiar with beekeeping.

Respecting Bee Space

A key principle of the Langstroth hive is the concept of "bee space"—a precise gap (6-9 mm) that bees will not fill with comb or propolis. The Auto Flow frames and boxes are engineered to maintain this critical dimension, ensuring bees can move freely and perform their natural functions without being impeded by the new technology.

The Core Innovation: The "Flow" Mechanism

The true departure from tradition lies entirely within the specialized "Flow Frames." These frames replace the standard wooden frames in the honey super (the box designated for honey storage).

Partially Formed Plastic Cells

Unlike traditional frames that require bees to build the entire comb from a wax foundation, Flow Frames contain a pre-formed matrix of partially-formed plastic honeycomb cells.

Bees enter the super, complete these cells with their own wax, and then fill them with honey, capping the cells with wax just as they would in a natural comb.

The Key-Activated "Splitting" Action

The patented mechanism is a series of vertical channels and moving parts within the plastic frame. When the beekeeper inserts and turns a special key or lever from outside the hive, the two sides of each cell shift vertically against each other.

This action splits the wax caps and turns the sealed honeycomb cells into open channels, allowing the honey inside to flow downwards.

Gravity-Fed, Undisturbed Collection

Once the cells are split, gravity does the rest. The honey drains through the newly formed channels, out a spout at the bottom of the frame, and through a tube directly into a collection jar.

The bees inside the hive remain largely undisturbed, as the hive is never opened and no smoke is used. Once the honey is drained, the beekeeper turns the key back, resetting the cells to their original position, ready for the bees to clean, repair, and refill.

Understanding the Trade-offs

While the design offers a significant benefit in harvesting ease, it introduces a new set of considerations that every beekeeper must weigh.

Reliance on Plastic Components

The Flow Frames are made from food-grade, BPA-free plastic. For some beekeeping purists who prioritize an all-natural environment of wood and wax, the introduction of plastic into the hive is a significant philosophical and practical drawback.

Cost and Complexity

An Auto Flow hive is considerably more expensive than a traditional Langstroth hive of the same size. The mechanical frames introduce moving parts that could potentially fail or become jammed, particularly if honey crystallizes within the cells.

Potential for Reduced Inspection

The primary benefit—not needing to open the hive for harvest—can inadvertently become a pitfall. Less frequent interaction may lead beekeepers to miss early signs of disease, pests like Varroa mites, or a failing queen, as these issues are typically identified during regular hands-on inspections.

Making the Right Choice for Your Goal

The Auto Flow design is a specialized tool, and its suitability depends entirely on your beekeeping philosophy and objectives.

- If your primary focus is low-impact hobby beekeeping: The Auto Flow hive is an excellent choice that dramatically simplifies honey harvesting and minimizes stress on the bees.

- If your primary focus is natural beekeeping or cost-efficiency: Traditional Langstroth hives with all-wax-and-wood frames remain the superior option, offering lower cost and no plastic components.

- If your primary focus is education and demonstration: This design provides an unparalleled, visible way to show how honey is made and harvested without disturbing the colony.

Ultimately, understanding this design is about recognizing it as a trade-off between convenience and traditional management practices.

Summary Table:

| Design Aspect | Key Feature | Benefit |

|---|---|---|

| Foundation | Based on Langstroth Hive | Ensures compatibility with standard equipment and practices. |

| Core Innovation | Patented Flow Frames with Partially-Formed Cells | Allows bees to fill and cap honey, then mechanically splits cells to drain honey. |

| Harvesting Method | Gravity-Fed System via External Key | Harvests honey without opening the hive, minimizing stress on the colony. |

| Considerations | Plastic Components & Higher Cost | Offers convenience but differs from traditional all-natural, cost-effective hives. |

Ready to modernize your apiary with efficient, bee-friendly equipment?

As HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-quality, innovative solutions through our wholesale-focused operations. The Auto Flow Beehive is a prime example of the advanced equipment we provide to help you achieve gentler honey harvesting and improved operational efficiency.

Let us help you stock the right tools for your customers' success. Contact our wholesale team today to discuss your needs and explore our full product catalog.

Visual Guide

Related Products

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- How does the honey harvesting process in a Flow Hive work? Revolutionize Your Apiary with Gravity Extraction

- What happens when the Flow Key is turned in the frame? A Gentle, On-Tap Honey Harvest

- What are the benefits of using Flow Hives? Experience Gentle, Effortless Honey Harvesting

- What is a bee hive that has a tap? Discover the Flow Hive for Easy Honey Harvesting

- What tips are recommended for successful Flow Hive beekeeping? Master the Hive for a Bountiful Harvest

- What frame size is compatible with Flow Hives? Essential Langstroth Standards for Your Beekeeping Success

- What is the cost comparison between a Flow Hive and a Langstroth hive? Initial Costs vs. Long-Term Value

- How does the Flow Hive address the issue of honey crystallization? Prevent and Manage Crystallization