At its core, an Automatic Viscous Liquid Filling Machine is designed to automate the entire process of dispensing thick, slow-flowing substances into containers. It replaces manual or semi-automatic labor to provide significantly faster and more precise filling for products like honey, gels, creams, and sauces, ensuring each container receives a consistent and accurate volume.

The true function of this machine is not just to fill containers, but to solve the fundamental manufacturing challenges of inefficiency, product waste, and inconsistent output that are common when handling viscous liquids.

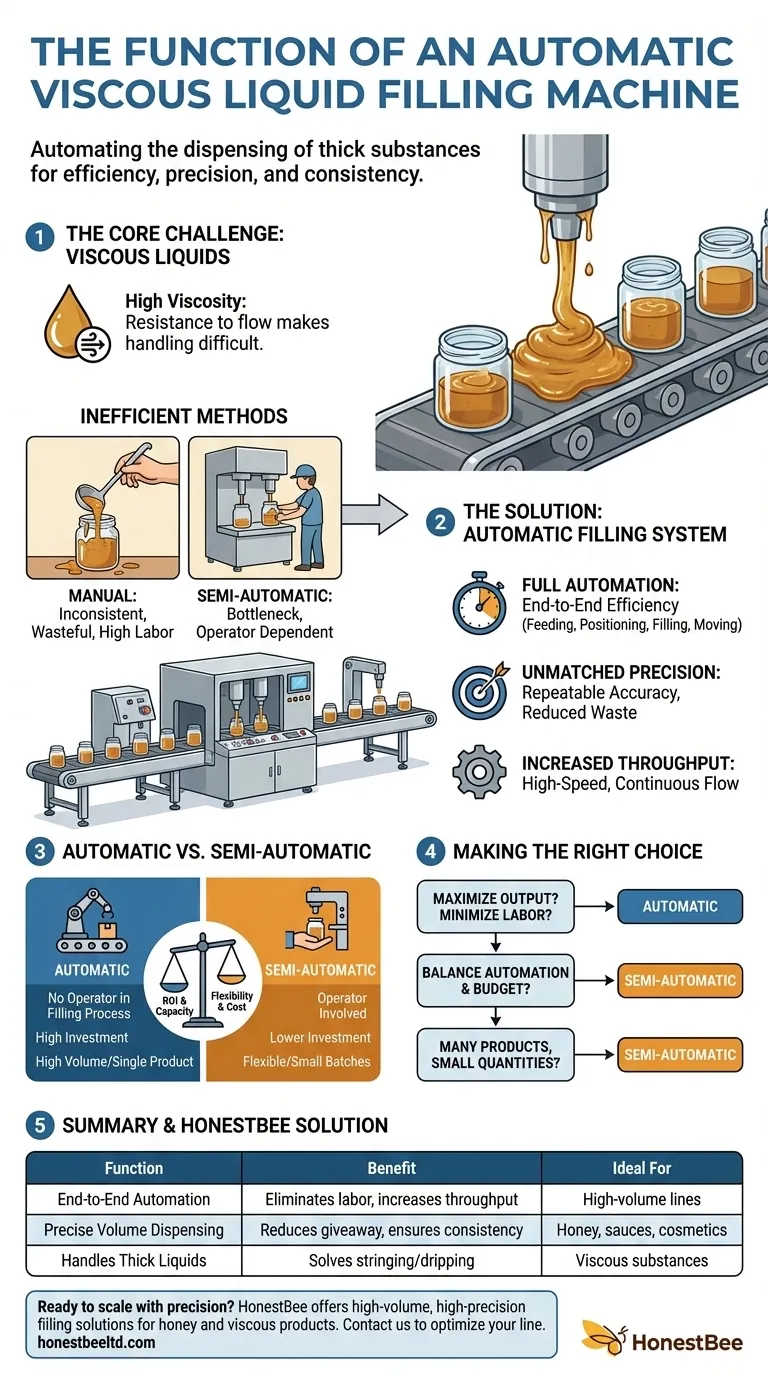

The Core Problem: The Challenge of Viscous Liquids

Understanding why these machines are necessary requires first appreciating the unique difficulties presented by thick liquids. Their resistance to flow makes them inherently hard to manage in a production environment.

Why Thick Liquids Are Hard to Handle

Viscosity, or a fluid's resistance to flow, is the central issue. Unlike water, viscous liquids like molasses or cosmetic creams do not pour quickly or cleanly.

This leads to problems like stringing (where a tail of product follows the nozzle), dripping, and slow fill cycles, all of which contribute to product waste and messy operations.

The Inefficiency of Simpler Methods

Manual filling is highly dependent on operator skill, leading to inconsistent fill levels, significant product spillage, and high labor costs. It is not a scalable solution for growing businesses.

Semi-automatic machines improve on this by automating the fill cycle itself, but they still require an operator for tasks like placing and removing each container. This creates a bottleneck that limits overall production speed.

How Automatic Viscous Fillers Solve the Problem

A fully automatic machine is an integrated system designed to overcome these challenges by removing manual intervention from the filling process. It creates a seamless, efficient, and reliable workflow.

Full Automation for End-to-End Efficiency

These systems automate every step of the production process. This typically includes feeding empty containers onto a conveyor, positioning them precisely under the fill nozzles, executing the fill, and then moving them downstream for capping and labeling.

By handling the entire sequence, the machine eliminates the stop-and-start nature of semi-automatic work, creating a continuous and much faster flow.

Unmatched Precision and Consistency

The primary value of automation is achieving repeatable accuracy. Automatic fillers use sophisticated mechanisms like piston or pump systems that dispense an exact volume of product, every single time.

This precision dramatically reduces product giveaway and ensures that every unit sold meets quality and regulatory standards for fill volume.

Increased Speed and Throughput

By automating all processes, these machines operate at a constant, high speed. This allows a business to significantly increase its units produced per hour.

This capability is critical for meeting large orders, satisfying retailer demand, and scaling the entire manufacturing operation without a proportional increase in labor.

Understanding the Trade-offs: Automatic vs. Semi-Automatic

Choosing the right machine involves weighing the benefits of full automation against its costs and complexities. A fully automatic line is not always the best solution for every scenario.

The Role of Manual Intervention

The key difference is the elimination of the operator from the direct filling process. In a semi-automatic setup, a worker is actively involved in handling each container, which offers flexibility but caps the maximum output.

An automatic line runs independently, with operators taking on a supervisory role to manage the overall process and supply bulk materials.

Initial Investment vs. Long-Term ROI

Automatic viscous fillers represent a significant capital investment compared to their semi-automatic counterparts. The cost includes not just the filler but also the necessary conveyors and controls.

However, the return on investment (ROI) is realized through lower labor costs, dramatically reduced product waste, and higher production capacity, which generates more revenue over time.

Flexibility and Batch Size

Semi-automatic machines often provide greater flexibility for small, diverse batches. Changeovers between different container sizes or products can be faster and simpler.

Automatic lines are optimized for high-volume production of a single product or products with similar container specifications. Frequent changeovers can be complex and time-consuming, reducing overall efficiency.

Making the Right Choice for Your Production Line

The decision to invest in an automatic viscous liquid filler depends entirely on your specific production goals, budget, and product mix.

- If your primary focus is maximizing output and minimizing labor: A fully automatic machine is the definitive solution for scaling high-volume production efficiently.

- If your primary focus is balancing automation with a lower initial budget: A semi-automatic machine provides a crucial step up from manual methods, increasing consistency without the cost of a full line.

- If your primary focus is producing many different products in small quantities: The superior flexibility and quicker changeover times of a semi-automatic machine may be the more practical choice.

Ultimately, selecting the right filling technology is about matching the machine's capabilities to your business's operational and strategic goals.

Summary Table:

| Function | Benefit | Ideal For |

|---|---|---|

| End-to-End Automation | Eliminates manual labor, increases throughput | High-volume production lines |

| Precise Volume Dispensing | Reduces product giveaway, ensures consistency | Products like honey, sauces, cosmetics |

| Handles Thick Liquids | Solves problems like stringing and dripping | Viscous substances (e.g., gels, creams) |

Ready to scale your production with precision?

If you're a commercial apiary or beekeeping equipment distributor looking to eliminate inefficiency and product waste, HONESTBEE has the solution. Our automatic viscous liquid filling machines are engineered for high-volume, high-precision filling of products like honey, ensuring consistent results and a strong return on investment.

Contact our experts today to discuss how we can optimize your filling line and boost your profitability.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Professional Durable Customizable Blister Packing Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Semi Automatic Round Bottle Labeling Machine

People Also Ask

- What is the technical necessity of standardized Honey Storage and Filling Machinery? Ensure Product Purity and Precision

- What is the main advantage of an automatic viscous liquid filling machine? Maximize Speed & Precision

- Why is high-precision honey-filling and packaging machinery necessary? Protect Bioactivity & Honey Quality

- How do automated honey filling and packaging machines contribute to the commercialization of honey products?

- Why is honey packaging important? Protect Quality, Build Your Brand & Boost Sales

- How do industrial-grade beehive manufacturing and honey-filling machinery convert ecological value? | HONESTBEE

- How does the horizontal sealing bar operate in a honey stick machine? Master the Final Sealing Step

- What role does a high-precision honey filling machine play? Elevate Forest Honey into Premium Commercial Commodities