At its core, a honey extractor motor provides the controlled power and torque needed to spin honeycombs. This action uses centrifugal force to efficiently extract honey without destroying the delicate wax structure of the comb.

The true value of a motor isn't just automation; it's about maximizing efficiency and preserving the honeycomb, a critical resource that directly impacts your hive's long-term health and productivity.

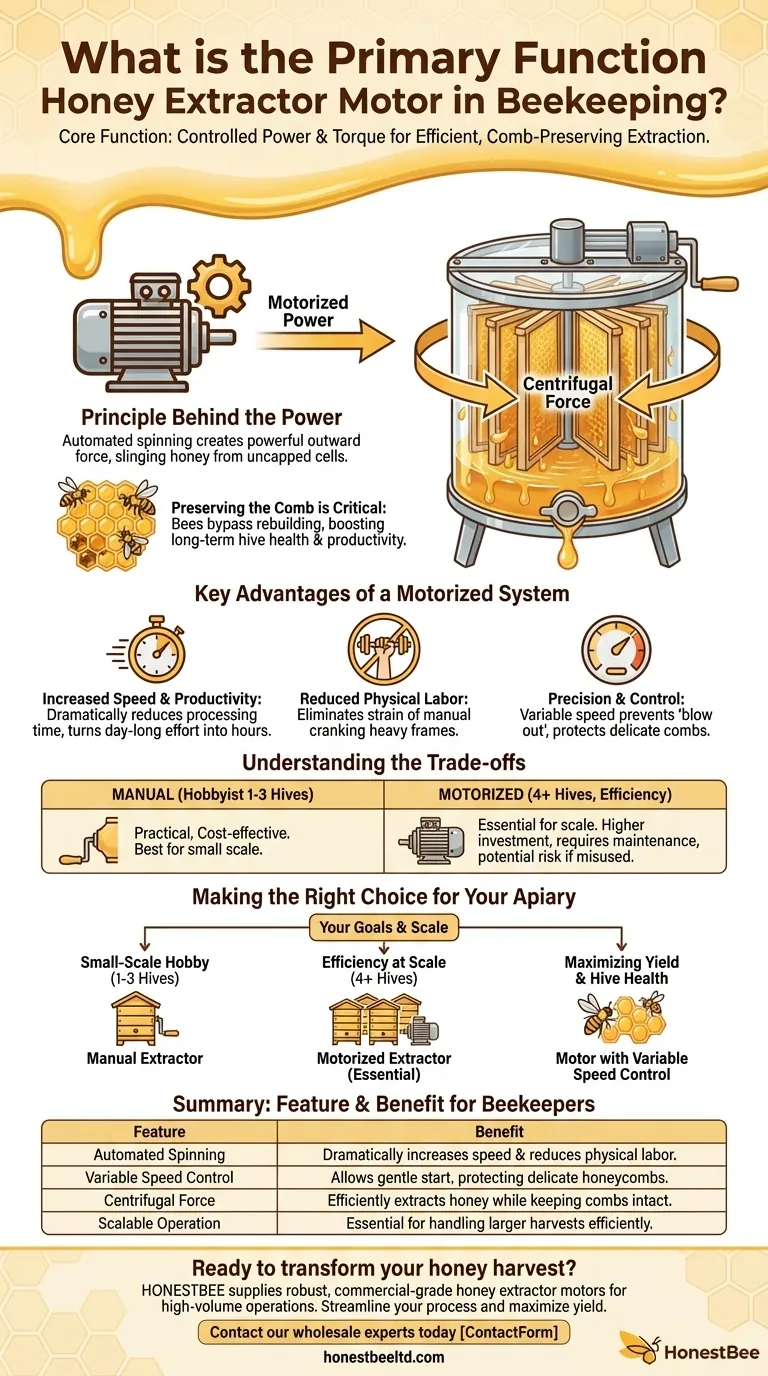

The Principle Behind the Power

A motorized extractor automates a simple physical principle. By understanding how it works, you can appreciate why the motor's control is so essential.

How Centrifugal Force Extracts Honey

When the extractor's basket spins, it creates a powerful outward force. This force slings the liquid honey from the uncapped wax cells to the inner wall of the extractor drum, where it drips down for collection.

Why Preserving the Comb is Critical

The honeycomb is the heart of the operation. Bees expend a tremendous amount of energy and resources to build this wax structure.

By keeping the combs intact, beekeepers can return them to the hive. The bees can immediately begin refilling them with honey, bypassing the lengthy and resource-intensive process of building new comb from scratch.

Key Advantages of a Motorized System

While manual extractors work, a motor introduces significant advantages, particularly as your beekeeping operation grows.

Increased Speed and Productivity

For beekeepers with multiple hives, a motor is a game-changer. It dramatically reduces the time required to process frames, turning a day-long manual effort into a task of a few hours.

Reduced Physical Labor

Manually cranking an extractor, especially one loaded with heavy frames of honey, is physically demanding. A motor eliminates this strain entirely.

Precision and Control

Modern extractor motors offer variable speed control. This allows for a gentle start to extract honey from the first side without the weight of the honey on the opposite side causing the comb to "blow out" and break. The speed can then be increased for maximum extraction.

Understanding the Trade-offs

A motor is a powerful tool, but it is not the right choice for every situation. Objectivity requires acknowledging its limitations.

Manual vs. Motorized

For a hobbyist with one or two hives, a simple hand-crank extractor is often more than sufficient. The added cost and complexity of a motorized system may not be justified.

The Risk of Improper Use

While a motor offers control, it can also cause damage if used incorrectly. Starting the spin too fast can destroy combs just as easily as clumsy manual handling. The operator's skill is still paramount.

Cost and Maintenance

A motorized extractor represents a higher initial investment than a manual model. It also introduces another component that may require maintenance or repair over its lifetime.

Making the Right Choice for Your Apiary

The decision to use a motorized extractor should be based on your specific goals and the scale of your operation.

- If your primary focus is a small-scale hobby (1-3 hives): A manual extractor is often the most practical and cost-effective solution.

- If your primary focus is efficiency at scale (4+ hives): A motorized extractor is essential for reducing labor and dramatically speeding up your processing time.

- If your primary focus is maximizing yield and hive health: A motor with variable speed control provides the precision needed to protect your combs for reuse, boosting your bees' productivity.

Ultimately, the right motor transforms honey extraction from a laborious chore into a streamlined and strategic part of your beekeeping process.

Summary Table:

| Feature | Benefit for Beekeepers |

|---|---|

| Automated Spinning | Dramatically increases processing speed and reduces physical labor. |

| Variable Speed Control | Allows for a gentle start to protect delicate honeycombs from damage. |

| Centrifugal Force | Efficiently extracts honey while keeping wax combs intact for hive reuse. |

| Scalable Operation | Essential for beekeepers with 4+ hives to handle larger harvests efficiently. |

Ready to transform your honey harvest? For commercial apiaries and distributors, the right motorized extractor isn't just a tool—it's an investment in productivity and hive health. HONESTBEE supplies robust, commercial-grade honey extractor motors and equipment designed for high-volume operations. Let us help you streamline your process and maximize your yield. Contact our wholesale experts today to discuss your apiary's needs.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- What are the main types of honey extractor machines? A Guide for Beekeepers

- What are radial honey extractors and what are their features? Maximize Your Honey Harvest Efficiency

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- How should an electric honey extractor be maintained and cared for? Protect Your Investment and Honey Purity

- What are the main types of honey extractors? Choose the Right Model for Your Apiary