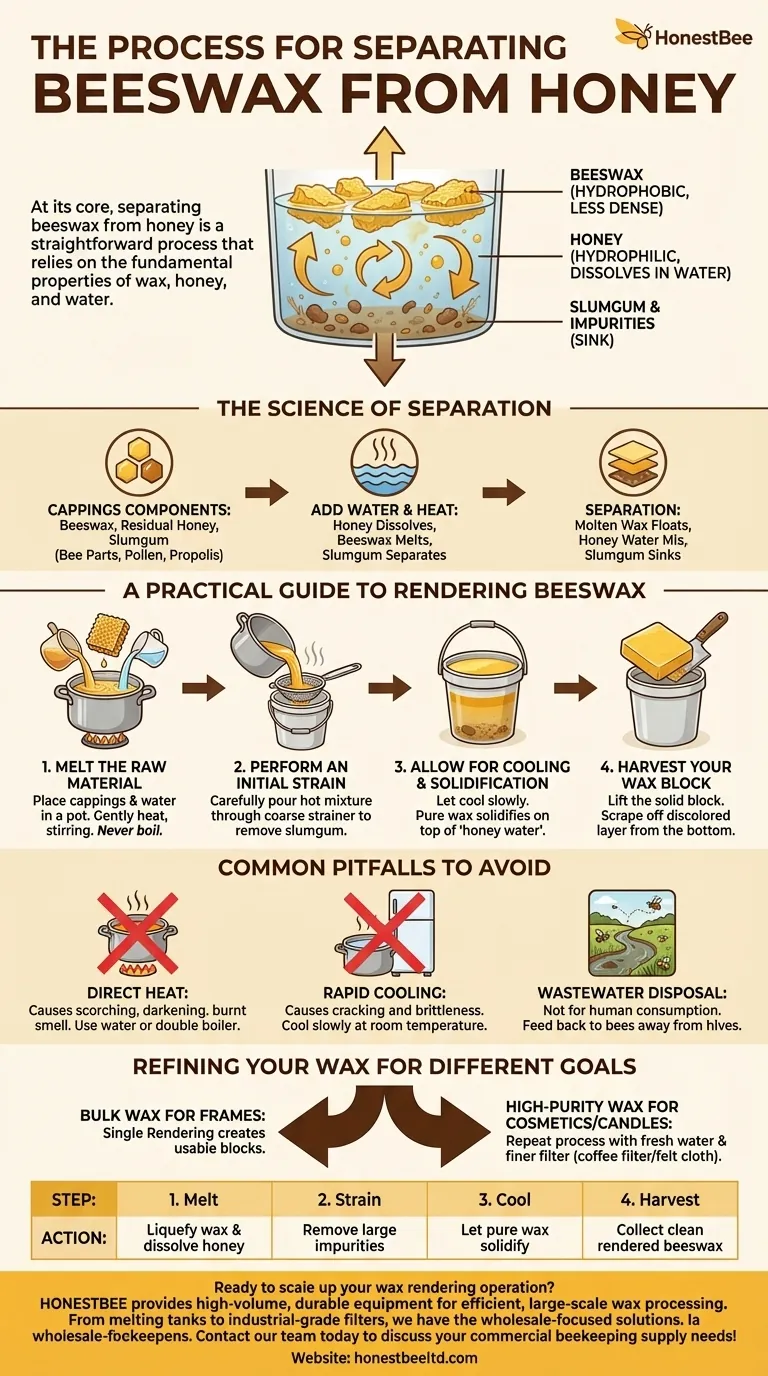

At its core, separating beeswax from honey is a straightforward process that relies on the fundamental properties of wax, honey, and water. By melting the raw comb and cappings in water, the less-dense beeswax naturally floats to the surface, while the water-soluble honey and heavier impurities sink, allowing for easy separation as the wax cools and solidifies.

The entire method hinges on a simple principle: beeswax is hydrophobic (repels water) and lighter than water, while honey is hydrophilic (dissolves in water). This allows water to act as the perfect medium to wash the honey away and float the pure wax to the top for collection.

The Science of Separation

To master the process, it's helpful to understand what you're working with and why the method is so effective. The raw material you collect after a honey harvest is a mix of three primary components.

### The Components in Your Cappings

The waxy material scraped off honeycomb cells, known as cappings, contains beeswax, residual honey, and various impurities like bee parts, pollen, and propolis, collectively called slumgum.

### How Water Simplifies Everything

When this mixture is heated in water, a separation occurs. The honey dissolves into the water. The beeswax melts and, being lighter than both the water and the debris, floats to the top. The heavier slumgum sinks to the bottom or gets trapped between the wax and water layers.

A Practical Guide to Rendering Beeswax

This step-by-step process will guide you through turning your sticky cappings into clean, usable blocks of beeswax. Safety is paramount, as hot wax can cause serious burns.

### Step 1: Melt the Raw Material

Place your wax cappings and comb pieces into a dedicated pot (not one used for food). Cover the wax with water, ensuring there is more water than wax. Gently heat the mixture, stirring occasionally until all the wax has melted. Never boil the mixture, as this can darken and damage the wax.

### Step 2: Perform an Initial Strain

Once the wax is fully melted, you need to remove the largest impurities. Carefully pour the hot liquid mixture through a coarse strainer or a double layer of cheesecloth set over a clean bucket or pot. This will catch the slumgum.

### Step 3: Allow for Cooling and Solidification

Let the strained, hot liquid sit undisturbed. As it cools over several hours, the pure, melted beeswax will rise to the very top and solidify into a hard cake or disc. The "honey water" and any remaining fine sediment will be trapped underneath.

### Step 4: Harvest Your Wax Block

Once the wax is completely solid, you can easily lift the block off the top of the water. The bottom of the wax block may have a thin, discolored layer of fine impurities. This can be easily scraped off with a hive tool or knife.

Common Pitfalls to Avoid

Rendering wax is simple, but a few common mistakes can impact the quality of your final product. Avoiding them ensures you get the best possible result.

### The Danger of Direct Heat

Never melt beeswax over direct heat without water. Wax is flammable and scorches easily, which darkens the color and gives it a burnt smell. Using a double boiler or melting it directly in water mitigates this risk entirely.

### The Mistake of Rapid Cooling

Avoid the temptation to speed up the cooling process by placing the pot in a freezer or refrigerator. Slow, gradual cooling at room temperature results in a solid, crack-free block of wax. Rapid cooling can cause it to crack and become brittle.

### Disposing of the Wastewater

The water left over after you remove the wax block will contain dissolved honey and sediment. It is not suitable for human consumption. Many beekeepers choose to feed it back to their bees in an open area away from the hives to prevent frenzy and robbing.

Refining Your Wax for Different Goals

The method described above produces a clean, crude block of beeswax. Depending on your intended use, you may want to refine it further.

- If your primary focus is bulk wax for starting new frames: A single rendering is perfectly sufficient to create usable blocks.

- If your primary focus is high-purity wax for cosmetics, salves, or high-end candles: You should repeat the process by re-melting your rendered wax block in fresh water and filtering it through a finer material, like a coffee filter or felt cloth, to achieve a superior level of purity.

By understanding this simple rendering process, you can efficiently transform a sticky byproduct of your honey harvest into a valuable, versatile, and beautiful natural resource.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Melt raw comb in water | Liquefy wax and dissolve honey |

| 2 | Strain the hot mixture | Remove large impurities (slumgum) |

| 3 | Allow to cool undisturbed | Let pure wax solidify on top |

| 4 | Harvest the wax block | Collect your clean, rendered beeswax |

Ready to scale up your wax rendering operation? As a trusted supplier for commercial apiaries and distributors, HONESTBEE provides the high-volume, durable equipment you need for efficient, large-scale wax processing. From heavy-duty melting tanks to industrial-grade filters, we have the wholesale-focused solutions to maximize your productivity and product purity. Contact our team today to discuss your commercial beekeeping supply needs!

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What are the features of industrial wax melters? Unlock Precision Purity for Commercial Beeswax Production

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening

- What are the primary products of honey bee farming besides honey? Discover the Hive's Hidden Treasures

- How do water jacket melters function? Achieve Gentle, Scorch-Free Melting for Sensitive Materials