The solar melter method is a technique that uses the sun's natural energy to gently melt and filter raw beeswax. It works by placing crushed combs or raw wax inside an insulated box with a glass top, which traps solar heat. As the wax melts, it flows through a filter into a collection tray, separating the pure wax from debris. This passive and energy-efficient process is particularly favored by beekeepers for processing wax from old honeycombs.

A solar melter provides an economical and low-effort way to render high-quality beeswax by leveraging solar power. Its primary advantage is its gentle, passive heating, which preserves wax quality and requires no electricity, though its effectiveness is entirely dependent on sufficient sunlight.

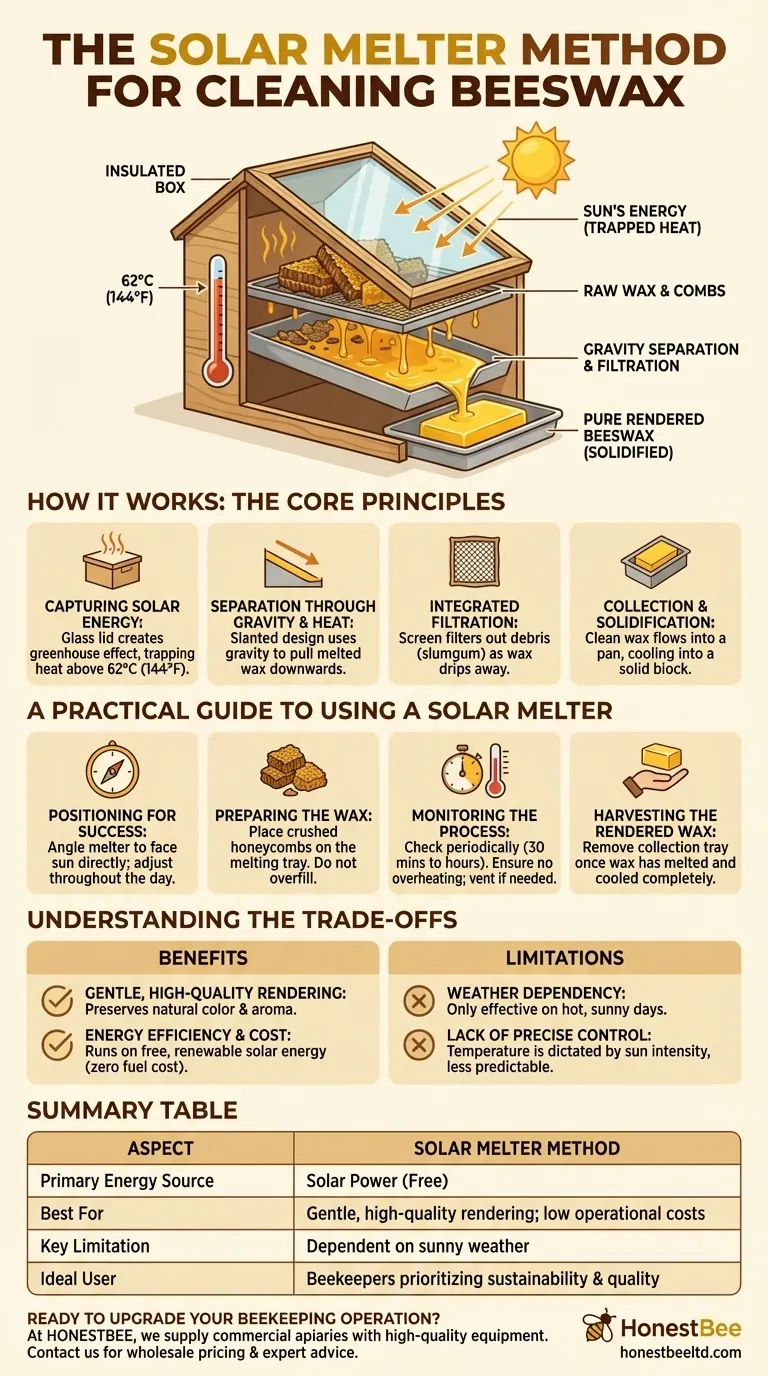

How a Solar Melter Works: The Core Principles

The effectiveness of a solar melter comes from its simple yet brilliant design, which combines several physical principles to separate pure wax from impurities.

Capturing Solar Energy

A solar melter is essentially a well-insulated box with a glass or clear polycarbonate lid. This design creates a greenhouse effect, trapping the sun's heat.

The internal temperature must rise above 62°C (144°F), the melting point of beeswax, to be effective. The insulated walls prevent this captured heat from escaping.

Separation Through Gravity and Heat

The melter is designed to sit at an angle, facing the sun. The raw honeycomb or wax chunks are placed on a screen or tray in the upper part of the box.

As the sun heats the interior, the wax liquefies. Gravity then pulls the liquid wax downwards, causing it to flow toward a collection point.

Integrated Filtration

The screen or pan holding the raw material serves as the first filter. As the wax melts and drips away, solid impurities like old cocoons, propolis, and other debris (often called "slumgum") are left behind.

Some models may include an additional, finer sieve near the collection spout to remove smaller particles before the wax is collected.

Collection and Solidification

The clean, liquid wax flows out of the main chamber and into a separate collection pan or mold. Here, it is allowed to cool slowly and harden into a solid block of clean, rendered beeswax.

A Practical Guide to Using a Solar Melter

While the process is largely passive, a few steps are crucial for achieving the best results and ensuring safety.

Positioning for Success

The most critical step is to position the melter so that it receives maximum direct sunlight. It should be angled to face the sun directly. You may need to adjust its position throughout the day to track the sun's path across the sky.

Preparing the Wax

Place your crushed honeycombs or chunks of raw wax onto the internal melting tray or mesh. Do not overfill the melter, as this can slow down the process and lead to an inefficient melt.

Monitoring the Process

Although the melter works on its own, it should not be left completely unattended. The process can take anywhere from 30 minutes to several hours depending on the sun's intensity and the volume of wax.

Using a thermometer can help you ensure the temperature doesn't get so high that it scorches the wax or creates a fire hazard, as beeswax is flammable at very high temperatures. If it gets too hot, you can partially vent the lid.

Harvesting the Rendered Wax

Once all the wax has melted and collected in the bottom tray, the process is complete. You can remove the tray and let the wax cool completely. The resulting block will be clean, high-quality beeswax, ready for use or further refinement.

Understanding the Trade-offs

A solar melter is an excellent tool, but it's essential to understand its advantages and limitations compared to other methods, such as a double boiler.

The Benefit: Gentle, High-Quality Rendering

The slow, low-temperature heating of a solar melter is one of its greatest assets. This gentle process prevents the wax from overheating or scorching, which preserves its natural yellow color and pleasant aroma, yielding a premium product.

The Benefit: Energy Efficiency and Cost

The most obvious advantage is that a solar melter runs entirely on free, renewable energy from the sun. It is an environmentally friendly method that requires no electricity or fuel, making its operational cost virtually zero.

The Limitation: Weather Dependency

The primary drawback is its complete reliance on the weather. The melter is only effective on hot, sunny days. It is useless on cloudy days, during rainy weather, or in winter in many climates, making it an unreliable option if you need to process wax on a tight schedule.

The Limitation: Lack of Precise Control

Unlike an electric melter or double boiler where you can instantly adjust the heat, a solar melter's temperature is dictated by the sun's intensity. This lack of precise control makes the process less predictable and requires a more hands-off, patient approach.

Is the Solar Melter Method Right for You?

Choosing your wax rendering method depends on your processing volume, climate, and desired level of control.

- If your primary focus is sustainability and low operational cost: The solar melter is an unparalleled choice, as it requires no electricity or fuel.

- If your primary focus is producing high-quality wax with minimal effort: The gentle, passive heat of a solar melter helps preserve the wax's natural properties and automates much of the filtration process.

- If your primary focus is speed and all-weather reliability: A double boiler or dedicated electric melter provides the on-demand control and year-round usability that a solar melter cannot.

Ultimately, the solar melter is an elegant and effective tool for any beekeeper with access to sunshine and a desire for pure, beautifully rendered beeswax.

Summary Table:

| Aspect | Solar Melter Method |

|---|---|

| Primary Energy Source | Solar Power (Free) |

| Best For | Gentle, high-quality rendering; low operational costs |

| Key Limitation | Dependent on sunny weather |

| Ideal User | Beekeepers prioritizing sustainability and quality |

Ready to upgrade your beekeeping operation?

At HONESTBEE, we supply commercial apiaries and equipment distributors with the high-quality, durable supplies needed for efficient wax rendering and hive management. Whether you're processing wax with a solar melter or scaling up your honey production, our wholesale-focused operations ensure you get the reliable equipment your business depends on.

Let's discuss your needs and how we can support your success. Contact our team today for wholesale pricing and expert advice.

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield

- How is honey harvested from a top bar hive system? Master the Crush and Strain Method for Pure Honey and Beeswax

- What is the primary function of solar or steam wax melters in the initial processing of raw beeswax? Maximize Wax Purity

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures