At its core, a syrup filling machine is specialized equipment designed to accurately and efficiently dispense syrup and other viscous liquids into containers like bottles or jars. It automates a critical step in the production process, moving beyond manual methods to provide consistency and speed required for commercial operations.

The fundamental purpose of a syrup filling machine is to solve the three biggest challenges of manual filling: inconsistent volumes, slow production speeds, and the risk of contamination. It replaces human variability with mechanical precision.

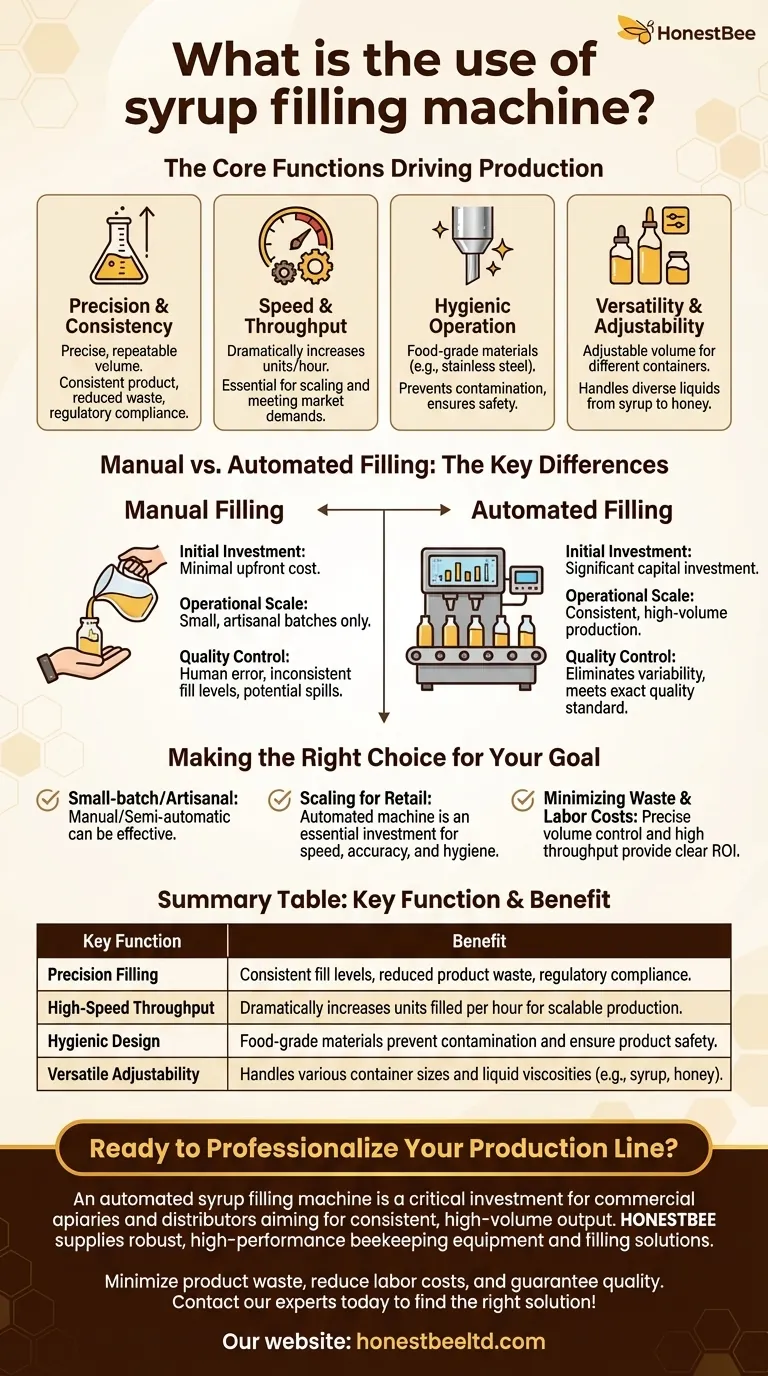

The Core Functions Driving Production

To understand the value of this equipment, we must look at its key operational functions. Each feature is engineered to address a specific bottleneck or quality control issue found in manual or less-advanced production lines.

Precision and Consistency

A primary function is delivering a precise, repeatable volume of product into every container. This ensures that each unit sold is consistent, which is vital for customer trust and regulatory compliance. This mechanical accuracy drastically reduces product waste caused by overfilling.

Speed and Throughput

These machines are built for speed, dramatically increasing the number of units filled per hour compared to manual labor. This high throughput is essential for businesses looking to scale their operations and meet larger market demands. An automatic machine controls the entire process, from positioning the container to filling it, without human intervention.

Hygienic Operation

Syrup filling machines are constructed using food-grade materials, such as stainless steel, that are easy to clean and sanitize. This design is critical for preventing contamination and ensuring the final product is safe for consumption, meeting strict industry hygiene standards.

Versatility and Adjustability

Modern machines are not limited to one container size or product type. They feature adjustable volume settings to easily switch between different jar or bottle sizes. This versatility allows a single machine to support a diverse product line, from thin syrups to thicker liquids like honey.

Manual vs. Automated Filling: The Key Differences

While manual filling has its place, the transition to an automated system represents a significant strategic decision. Understanding the trade-offs is crucial for any growing business.

Initial Investment

The most obvious difference is the upfront cost. An automated filling machine is a significant capital investment, whereas manual filling requires minimal initial expense. However, the machine's long-term return is measured in reduced labor costs and minimized product loss.

Operational Scale

Manual filling is suitable for very small, artisanal batches where variability might even be part of the charm. However, it is impossible to scale efficiently. An automated machine is a necessity for any operation aiming for consistent, high-volume production for retail or wholesale distribution.

Quality Control

Human error is a major factor in manual filling, leading to inconsistent fill levels and potential spills. A properly calibrated machine eliminates this variability, ensuring every product that leaves the facility meets the exact same quality standard.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in a syrup filling machine depends entirely on your production goals and business scale.

- If your primary focus is small-batch or artisanal production: Manual filling can be effective, but a semi-automatic machine can provide a major consistency boost without the cost of a fully automated line.

- If your primary focus is scaling production for retail: An automated filling machine is an essential investment for achieving the speed, accuracy, and hygiene required to compete.

- If your primary focus is minimizing product waste and labor costs: The machine's precise volume control and high throughput provide a clear and measurable return on investment over time.

Investing in this technology is a deliberate step toward professionalizing your production line and guaranteeing quality at scale.

Summary Table:

| Key Function | Benefit |

|---|---|

| Precision Filling | Consistent fill levels, reduced product waste, regulatory compliance. |

| High-Speed Throughput | Dramatically increases units filled per hour for scalable production. |

| Hygienic Design | Food-grade materials prevent contamination and ensure product safety. |

| Versatile Adjustability | Handles various container sizes and liquid viscosities (e.g., syrup, honey). |

Ready to Professionalize Your Production Line?

An automated syrup filling machine is a critical investment for commercial apiaries and beekeeping equipment distributors aiming for consistent, high-volume output. HONESTBEE supplies robust, high-performance beekeeping equipment, including filling solutions designed for the demands of wholesale operations.

We can help you minimize product waste, reduce labor costs, and guarantee the quality of your honey and syrup products. Contact our experts today to find the right filling solution to scale your business!

Visual Guide

Related Products

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

- Semi Automatic Round Bottle Labeling Machine

- Professional Durable Customizable Blister Packing Machine

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- Why is industrial-grade honey-filling equipment essential? Protect Bioactive Supplements & Potency

- What are the primary advantages of high-precision honey-filling machines? Boost Efficiency & Quality in Commercial Labs

- Why is automated honey filling and labeling machinery essential? Scale Your Honey Export to High-End Global Markets

- What are the benefits of using automated honey filling machines? Boost Efficiency and Preserve Quality

- How do automated filling and sealing machines contribute to the stability of bee pollen? Protect Potency and Shelf Life

- What are the advantages of automated honey filling machines vs manual? Scale Your Supply Chain Value

- How does a heating mechanism in a honey filling machine help? Unlock Speed, Accuracy & Premium Quality

- Why use professional industrial honey-filling machines? Boost Your Production Efficiency and Market Reach