For most craft and DIY projects, the primary tool used for embossing is a manual or electronic die-cutting machine. These machines apply precise pressure to a "sandwich" of plates, an embossing folder, and your material (like paper) to create a raised, textured design. While these are the most common tools for hobbyists, the term "embossing machine" also covers highly specialized industrial equipment for materials ranging from metal and leather to beeswax.

The specific machine used for embossing is determined entirely by the material being processed and the scale of the operation. While crafters use die-cutting machines for paper, industries use powerful, specialized presses for everything from metal plates to beeswax foundation sheets.

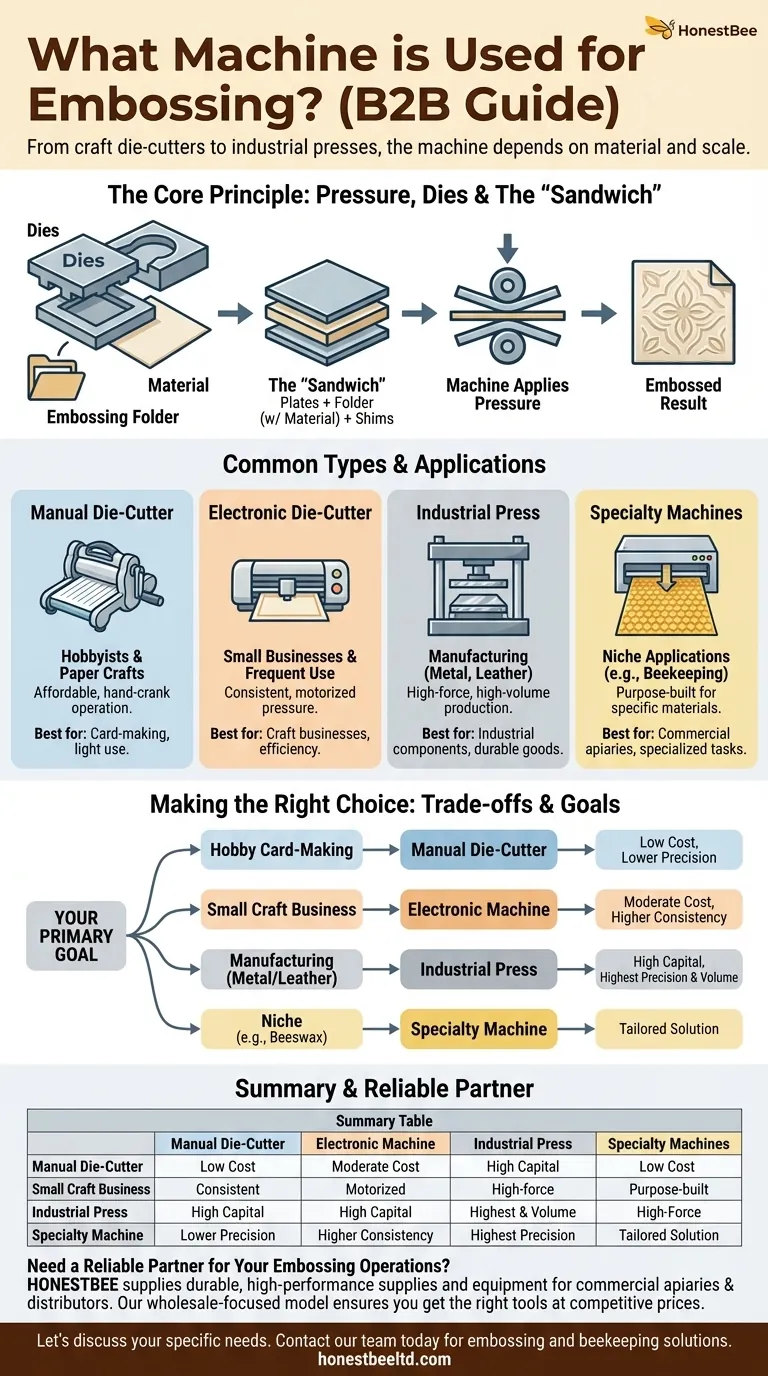

The Core Principle: Pressure and Dies

Embossing, at its heart, is a simple mechanical process. The machine is just a tool designed to apply force in a controlled and repeatable way.

How Embossing Works

The process involves pressing a material, such as paper or a thin metal sheet, between two interlocking molds or "dies." One die has a raised design, and the other has a matching recessed design. The machine applies force, permanently reshaping the material to match the pattern.

The "Embossing Folder" in Crafting

For paper crafts, the "dies" are contained within a simple, hinged plastic tool called an embossing folder. The inside of the folder has the raised and recessed pattern. You simply place your paper inside the folder to prepare it for the machine.

The "Sandwich" Concept

The term "sandwich" refers to the specific stack of plates, the embossing folder (with paper inside), and any necessary shims or mats. Each machine manufacturer has a precise, required order for this stack to achieve the correct pressure without damaging the machine or the materials.

Common Types of Embossing Machines

The right machine depends entirely on your goal, from creating a single greeting card to manufacturing thousands of parts.

Manual Die-Cutting & Embossing Machines

These are the most common tools for hobbyists. They operate with a hand crank that feeds the "sandwich" through two pressure rollers. They are relatively affordable, portable, and require no electricity.

Electronic Die-Cutting & Embossing Machines

These are the motorized equivalent of manual machines. With the push of a button, the machine automatically pulls the sandwich through its rollers. This provides more consistent pressure and is easier for users with limited hand strength, though they come at a higher cost.

Specialized Industrial Presses

For commercial and industrial applications, embossing is done on large hydraulic or pneumatic presses. These machines can exert immense force, allowing them to emboss durable materials like sheet metal, leather hides, and thick plastic for applications like license plates, book covers, and industrial components.

Niche Application Machines

Some industries require extremely specialized embossers. For example, the beekeeping industry uses beeswax embossing machines to press a honeycomb pattern onto flat sheets of beeswax, creating a foundation that encourages bees to build their comb. This highlights how a machine is always tailored to its specific task.

Understanding the Trade-offs

Choosing a machine involves balancing cost, precision, and the scope of your work.

Cost and Accessibility

Manual machines are the entry point, offering the lowest cost and widest availability. Electronic machines represent a moderate investment, while industrial presses are significant capital expenditures.

Precision and Consistency

Electronic machines generally offer better consistency than manual versions, as the motor speed and pressure are constant. Industrial presses are engineered for the highest levels of precision and repeatability across thousands of impressions.

Material Versatility

Crafting machines are designed primarily for paper, cardstock, and other thin materials like craft foils. Attempting to use materials that are too thick or rigid can permanently damage the machine. Industrial machines are built specifically for tougher materials.

Making the Right Choice for Your Project

Use your primary goal to guide your decision.

- If your primary focus is hobby card-making and paper crafts: A manual die-cutting and embossing machine offers the best balance of cost and capability.

- If your primary focus is running a small craft business or frequent crafting: An electronic machine will save you time and ensure a more consistent, professional result.

- If your primary focus is manufacturing with metal, leather, or other durable materials: You must research specialized industrial presses designed for your specific material and production volume.

- If your primary focus is a niche application like beekeeping: You will need to source a purpose-built machine designed exclusively for that task.

Ultimately, understanding your specific material and production goal is the key to selecting the correct embossing equipment.

Summary Table:

| Machine Type | Best For | Key Feature |

|---|---|---|

| Manual Die-Cutter | Hobbyists & Paper Crafts | Affordable, hand-crank operation |

| Electronic Die-Cutter | Small Businesses & Frequent Use | Consistent, motorized pressure |

| Industrial Press | Manufacturing (Metal, Leather) | High-force, high-volume production |

| Specialty Machines | Niche Applications (e.g., Beekeeping) | Purpose-built for specific materials |

Need a Reliable Partner for Your Embossing Operations?

Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the durable, high-performance supplies and equipment you need to scale your operations efficiently. Our wholesale-focused model ensures you get the right tools for the job at competitive prices.

Let's discuss your specific needs. Contact our team today to find the perfect embossing and beekeeping solutions for your business.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Automatic In-Line Flat Surface Labeling Machine

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Mini Desktop Bee Hive Frame Forming Making Machine

People Also Ask

- What is the primary function of the manual honeycomb embossing machine? Gain Control Over Your Hive's Foundation

- What additional preparation is needed for the work area when making beeswax sheets? Set Up a Professional Production Line

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets

- What are the benefits of using a machine to produce beeswax foundation sheets? Achieve Superior Hive Health & Efficiency

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production