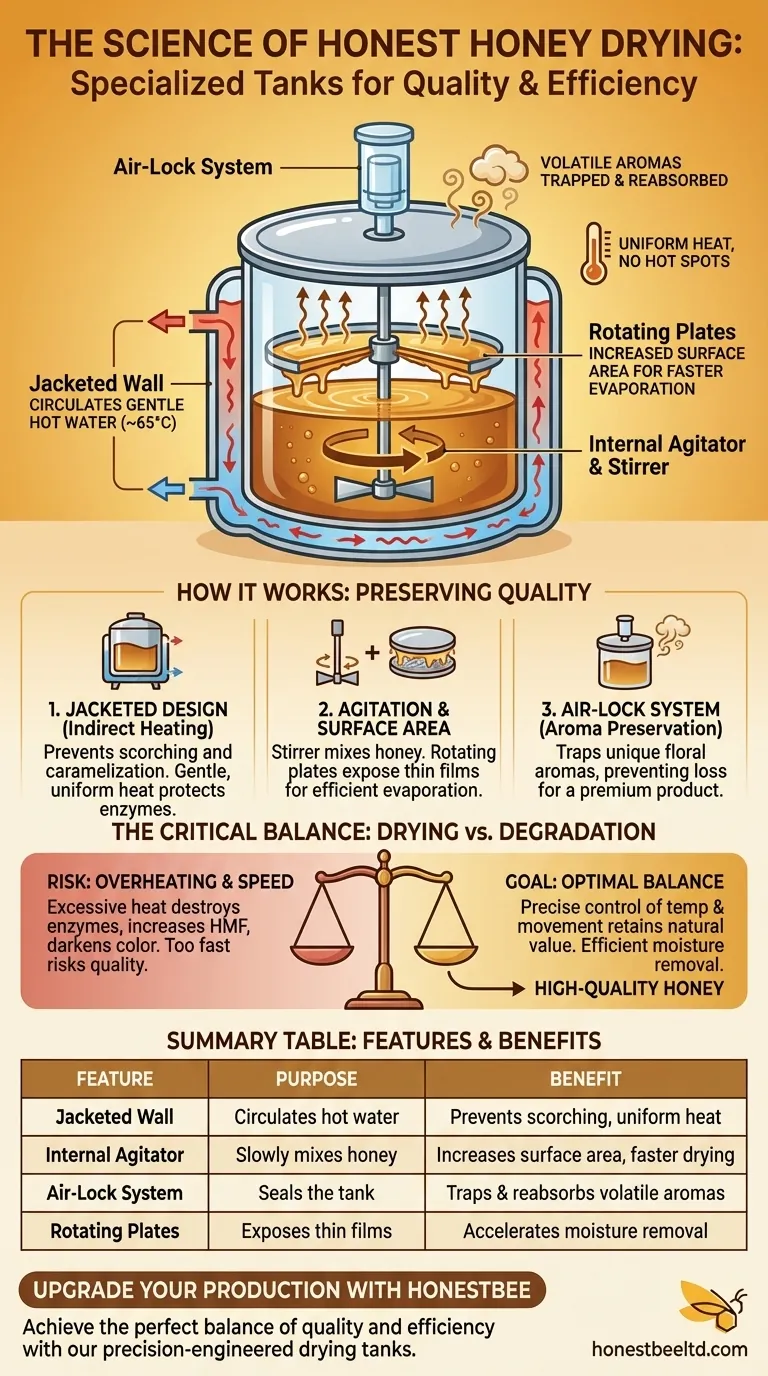

At its core, the honey drying process utilizes a specialized, sealed tank designed for indirect heating and agitation. This is typically an air-lock tank or a jacket-equipped drum that circulates hot water around the honey rather than applying direct heat. This design is critical for gently removing excess water while preserving the honey's delicate aromas, flavors, and beneficial enzymes.

The essential challenge in drying honey is removing water without degrading its quality. The specialized tank solves this by using gentle, indirect heat from a water jacket and internal agitators to increase surface area, ensuring moisture evaporates efficiently while the honey’s valuable characteristics are protected.

How a Honey Drying Tank Actually Works

To understand the equipment, you must first understand the goal: reducing the water content of honey (often from 25-30% down to around 19%) without "cooking" it. The design of the drying tank is entirely focused on this delicate balance.

The Jacketed Design for Indirect Heating

The most critical feature is the jacketed wall. Instead of applying a flame or heating element directly to the tank's surface, hot water is circulated through an outer jacket that surrounds the inner drum holding the honey.

This method provides gentle and uniform heat, preventing hot spots that could scorch or caramelize the honey. A conventional approach heats the water to around 65°C (149°F) to facilitate evaporation without damaging the honey's composition.

The Role of Agitation and Surface Area

Inside the tank, mechanical components are used to speed up the process. A central stirrer or agitator continuously and slowly mixes the honey.

This constant motion ensures all the honey comes into contact with the heated walls for even drying. Some dryers also incorporate a system of rotating plates, which pick up thin films of honey and expose them to the air in the tank's headspace, dramatically increasing the surface area for faster water evaporation.

The Air-Lock System for Aroma Preservation

High-quality honey is defined by its unique floral aromas, which are volatile and can easily be lost during heating. The process takes place in a sealed or air-lock tank to trap these compounds.

By keeping the system closed, the fragrant aromas are contained and reabsorbed into the honey, while the water vapor is managed separately. This is essential for producing a premium final product.

The Critical Balance: Drying vs. Degradation

Using this equipment correctly involves navigating a crucial trade-off. The goal is to remove water as efficiently as possible without triggering the chemical reactions that degrade the honey.

The Risk of Overheating

If the temperature rises too high or is applied for too long, the honey's quality suffers significantly. Excessive heat destroys natural enzymes, can increase undesirable compounds like HMF (hydroxymethylfurfural), and darkens the honey's color, all of which are negative quality indicators.

The Challenge of Speed

While faster agitation and higher temperatures will speed up moisture removal, they also increase the risk of quality degradation. The most effective operations find the optimal balance that meets production timelines without compromising the honey’s natural integrity.

Making the Right Choice for Your Goal

The specific parameters you use depend entirely on the intended quality and scale of your final product.

- If your primary focus is artisanal quality: Prioritize lower temperatures and slower, gentler agitation within a well-sealed air-lock system to retain the maximum aroma and preserve all natural enzymes.

- If your primary focus is commercial efficiency: Utilize a system with rotating plates to maximize surface area, but carefully monitor the temperature to ensure it remains within the safe threshold to prevent quality degradation.

Ultimately, mastering the honey drying process is about precise control over temperature and movement to protect the product's natural value.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Jacketed Wall | Circulates hot water for indirect heating | Prevents scorching, ensures uniform heat |

| Internal Agitator | Slowly mixes honey | Increases surface area for faster evaporation |

| Air-Lock System | Seals the tank during drying | Traps and reabsorbs volatile aromas |

| Rotating Plates (Optional) | Exposes thin honey films to air | Accelerates moisture removal for efficiency |

Upgrade Your Honey Production with Professional Drying Equipment

Struggling to balance drying efficiency with honey quality? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, precision-engineered honey drying tanks. Our jacketed and air-lock systems are designed to protect your honey's delicate flavors and enzymes while meeting your production scale demands.

Let us help you achieve the perfect balance between quality and efficiency. Contact our experts today to discuss a tailored solution for your operation.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Stainless Steel Honey Storage Tank with Lid for Honey

- Stainless Steel Uncapping Tank with Stand and Strainer

People Also Ask

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation

- How to remove humidity from honey? Protect Your Harvest from Fermentation

- How does a honey dryer remove moisture from honey? Achieve Perfect Honey Stability with Controlled Drying

- How much honey can a honey dryer process and by what percentage does it reduce moisture? Optimize Your Honey Production

- What is the recommended drying temperature and moisture content for honey? Preserve Quality & Prevent Fermentation